Negative refraction single-element polarization beam-splitting prism and polarization beam-splitting method

A beam-splitting prism and negative refraction technology, which is applied in the direction of polarizing elements, can solve the problems of composite prisms that consume large raw materials, low device laser damage resistance threshold, and general mechanical properties, and achieve high technical performance and reliability, anti-light High damage threshold, adjustable beam splitting angle and multiple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

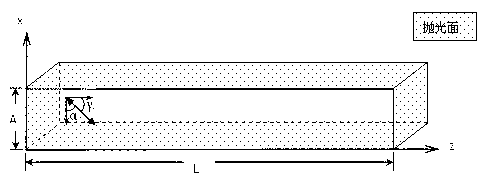

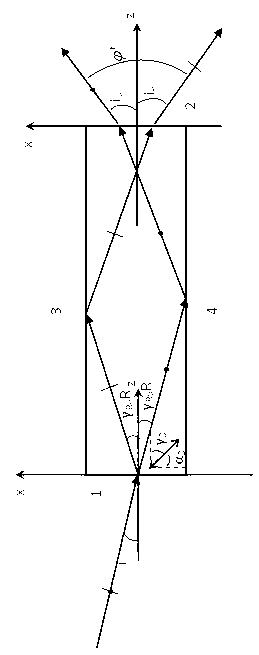

[0023] A polarizing beam splitting prism with a negative refraction unit. Its structure and splitting light path are as follows: figure 1 and 2 shown. The double arrows in the figure indicate the direction of the optical axis of the uniaxial birefringent crystal, and the cosine of the direction of the optical axis is (cosα 0 , cosγ 0 ). The design idea is as follows: unpolarized light enters the end face 1 of the prism at an incident angle i, and the light e is negatively refracted, and the refraction angle is γ Re , and then totally reflected by the interface 3 to the end face 2, and then by the refraction angle i e shoot. o The light is refracted at the end face 1, and is totally reflected to the end face 2 through the interface 4, at the refraction angle i o shoot.

[0024] Such as figure 1 The shown unit negative refraction polarizing beam splitter prism is made of a monolithic rectangular parallelepiped structure made of Iceland stone crystal. Reflector 3 and bo...

Embodiment 2

[0027] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that the crystal optical axis angle is 25 degrees, and the beam splitting angle is 15.87 degrees.

Embodiment 3

[0029] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that the crystal optical axis angle is 30 degrees, and the beam splitting angle is 18.39 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com