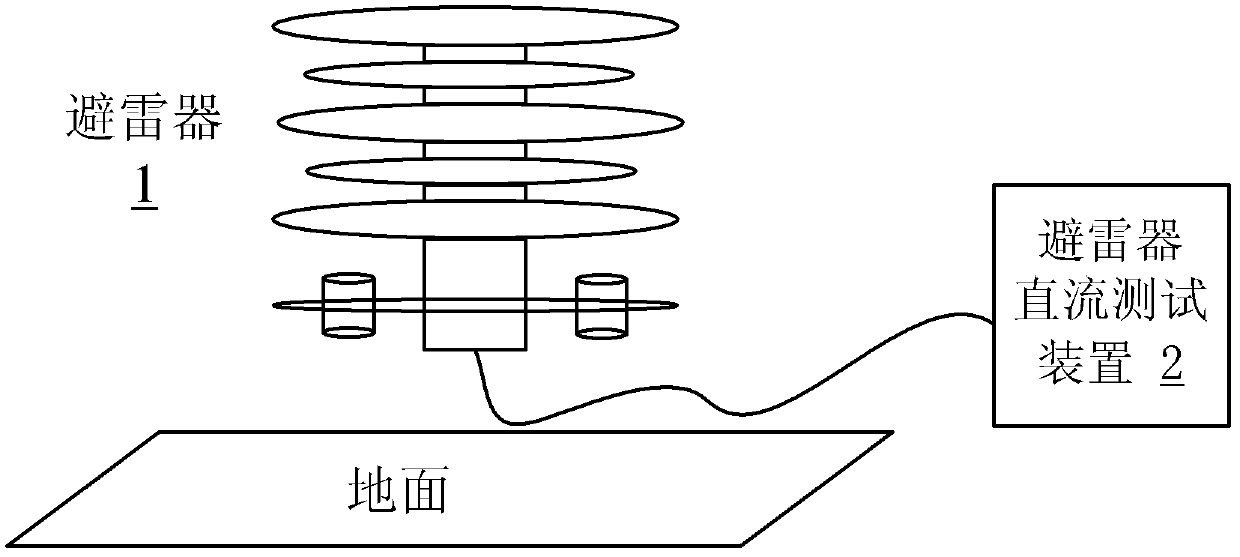

Lightning arrester direct current test system

A DC test and arrester technology, applied in the field of electric power applications, can solve the problems of unfavorable standardized test sites, low safety, and aggravated discharge conditions, and achieve the effects of avoiding floating potential discharge, reducing floating potential, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

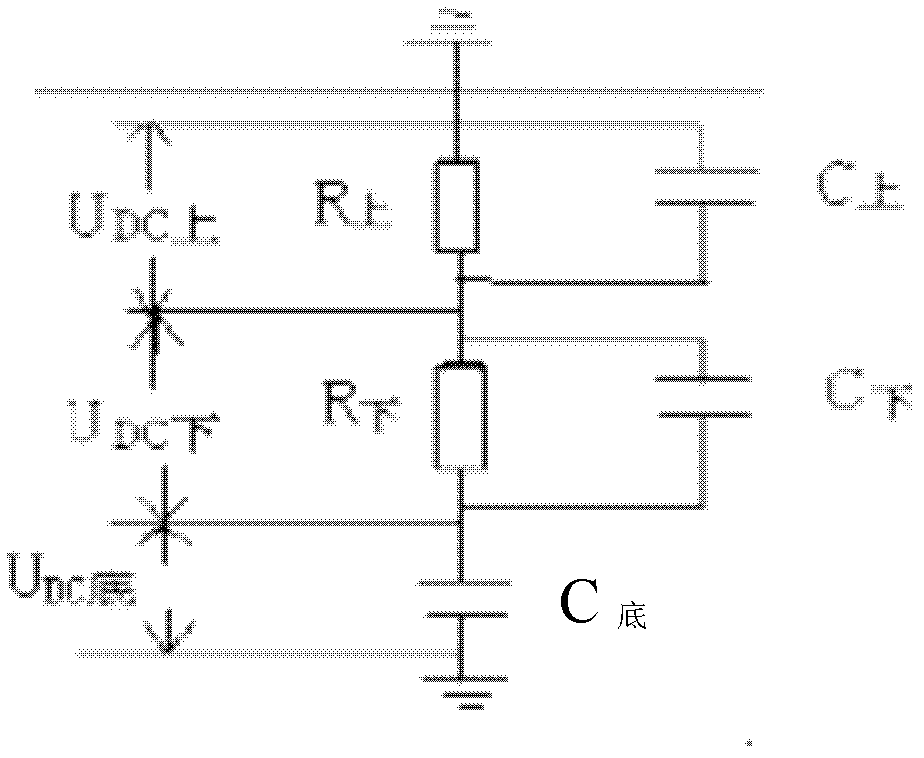

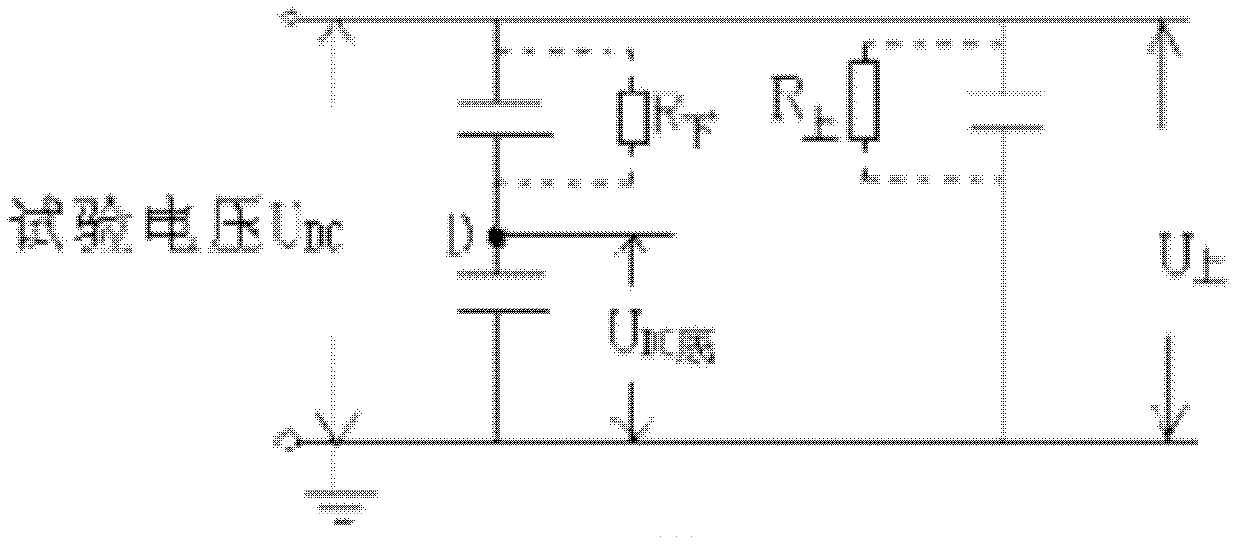

[0026] figure 1 It is a schematic diagram of the internal circuit of the arrester when the traditional test method is adopted according to the related technology, please refer to figure 1 When the traditional test method is adopted, when the test voltage applied to the arrester (for example, 220kV zinc oxide arrester) is less than or equal to the initial operating voltage, the upper and lower sections can be regarded as both composed of pure capacitors; When the test voltage is increased to be greater than the initial operating voltage, the upper and lower sections can be regarded as lossy capacitors, and the base can be regarded as a pure capacitor. Under normal circumstances, the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com