Measuring device and calibration method for optical lens distortion

A measuring device and optical lens technology, applied in the field of optical lens, can solve problems such as inaccurate correction effect and inability to obtain corrected images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

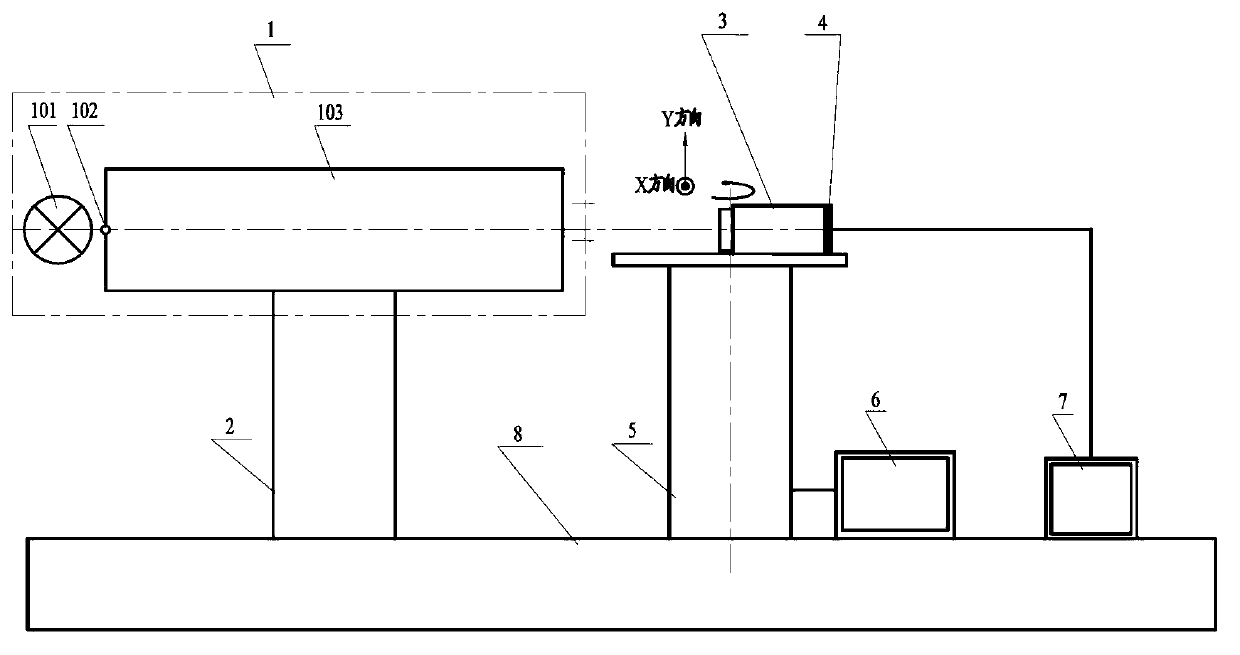

[0037] see first figure 1 , figure 1 It is a structural schematic diagram of the lens distortion measuring device to be tested in the present invention. It can be seen from the figure that the optical lens distortion measuring device of the present invention comprises a single starlight simulator 1, an adjustment frame 2, a lens to be tested 3, a CCD camera 4, a one-dimensional air bearing turntable 5, an angle encoder 6, a computer 7 and an optical The platform is composed of 8, and the positional relationship of the above components is as follows:

[0038] The adjustment frame 2 and the one-dimensional air-floating turntable 5 are placed on the optical platform 8, and the single star simulator 1 is composed of an integrating sphere light source 101, a collimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com