Sand coated iron mould casting device and casting technology of three-part-box ring type casting

A sand-coated iron mold and casting process technology, which is applied in the field of sand-coated iron mold casting, can solve the problems of losing the sand-coated iron mold technology, large sand core size, and inability to release the mold smoothly, so as to reduce human influence factors, Less dust, good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing of specification sheet and specific embodiment:

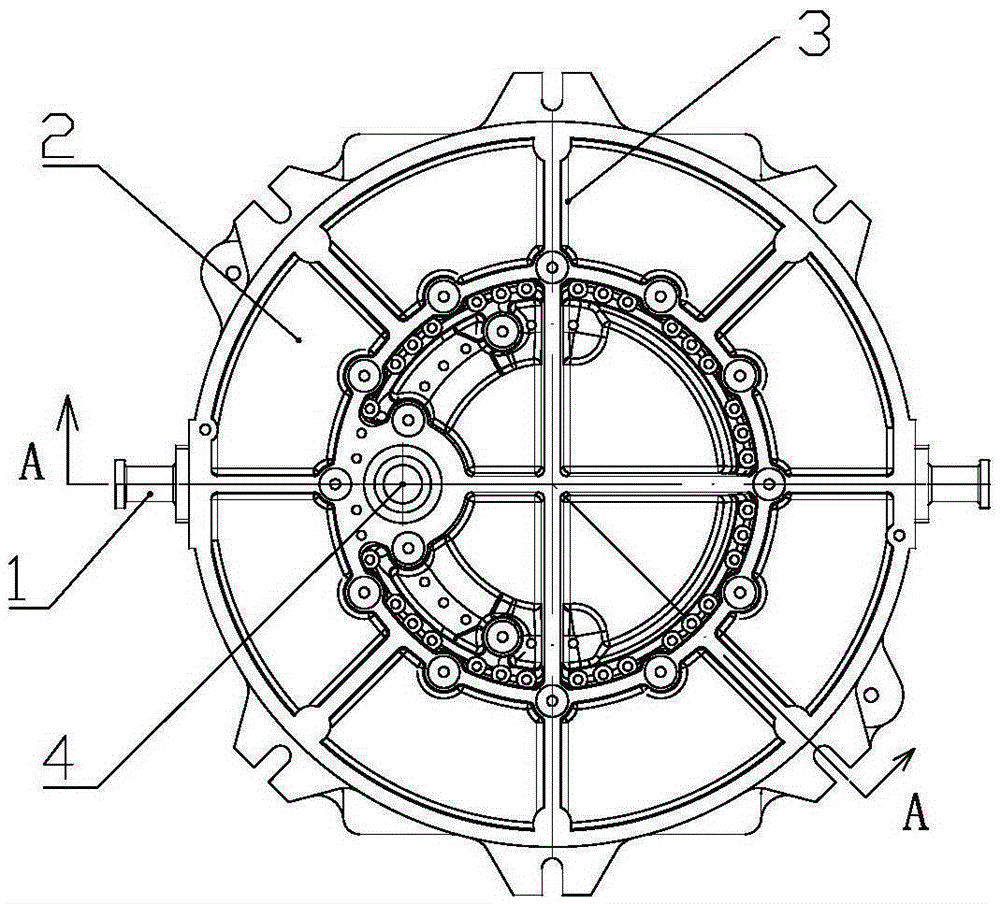

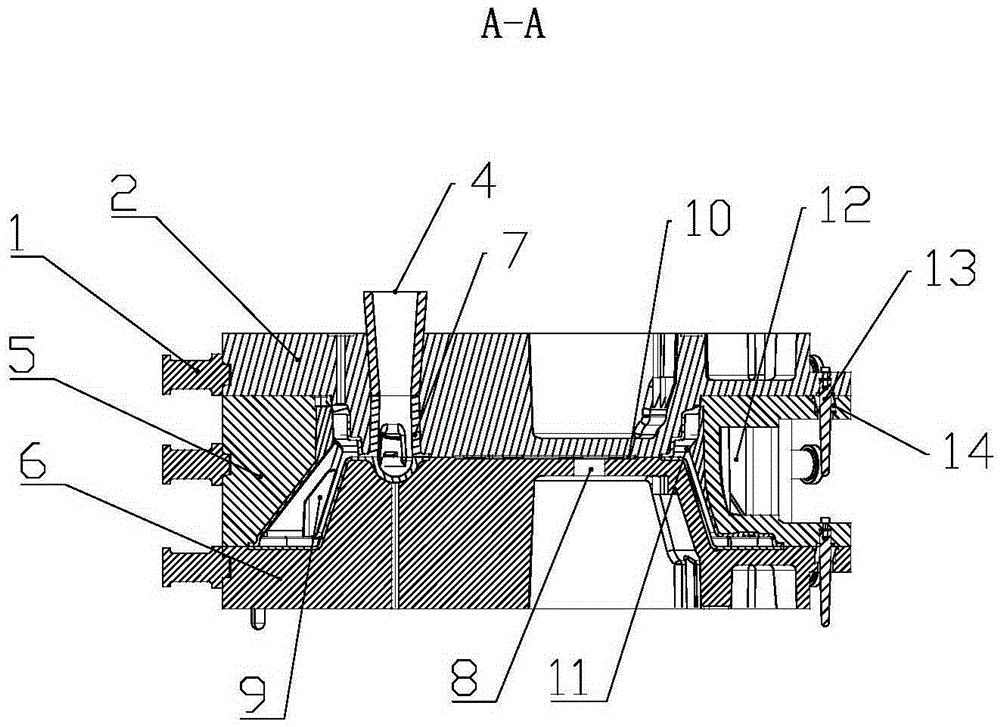

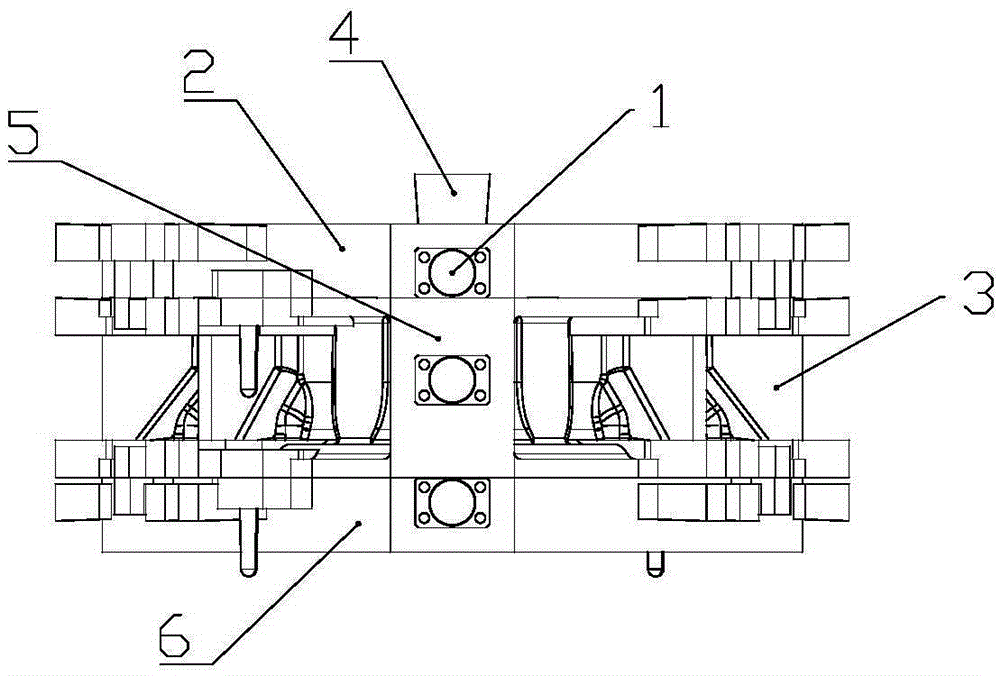

[0045] like figure 1 , figure 2 and image 3As shown, the iron mold sand-covered casting device for three open-box ring castings includes an upper sand box 2, an upper mold forming the cavity of the upper sand box, a lower sand box 6 and a lower mold forming the cavity of the lower sand box, and the upper mold There is a pouring system on the top, and it also includes a middle sand box 5 and a middle mold forming a middle sand box cavity. The middle sand box 5 is located between the upper sand box 2 and the lower sand box 6; the middle mold is provided with a columnar middle mold. Block 15, the back side of the middle mold movable block 15 is provided with a middle mold insert, and the middle mold movable block 15 and the middle mold insert are close together; between the middle sand box 5 and the upper sand box 2 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com