Three-dimensional scanner measuring method and device

A measurement method and technology of a measurement device, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as large errors, and achieve the effect of avoiding huge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical scheme of the present invention and its principles are further described in detail below in conjunction with the accompanying drawings of the embodiments:

[0034] 1. The principle of sinusoidal virtual light field generation

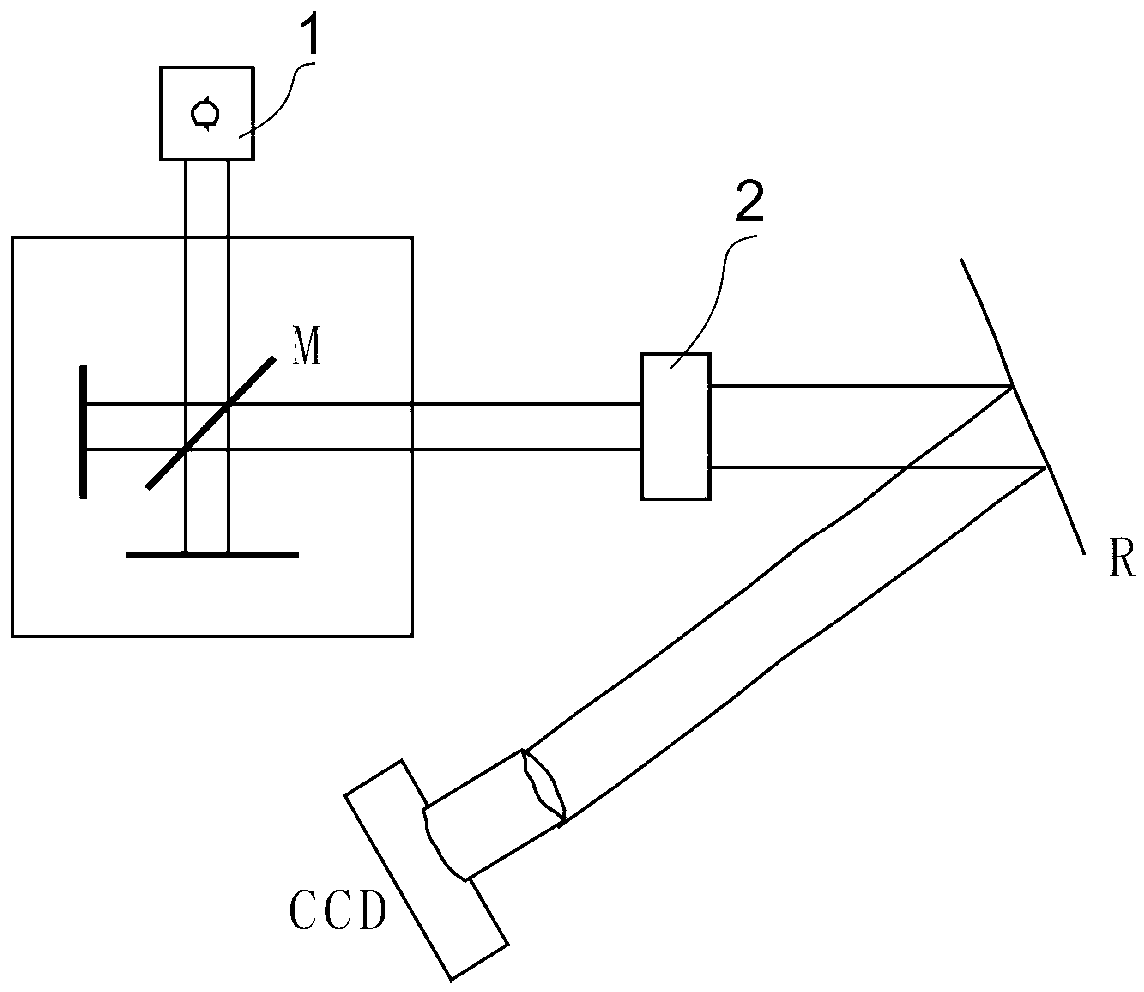

[0035] Illumination objects are projected for virtual sinusoidal gratings using a Michelson interferometer generation method. Such as figure 1 As shown, the required spatial carrier frequency can be obtained by adjusting the mirror M. R in the figure is the reference plane. The virtual sinusoidal grating is projected onto the reference plane R by the projection system, and then captured by the CCD camera. Finally, the captured data is sent to the computer for processing. The light intensity distribution can be expressed as:

[0036]

[0037] The above formula expresses the grating position offset due to the projection optical axis being perpendicular to the reference plane R.

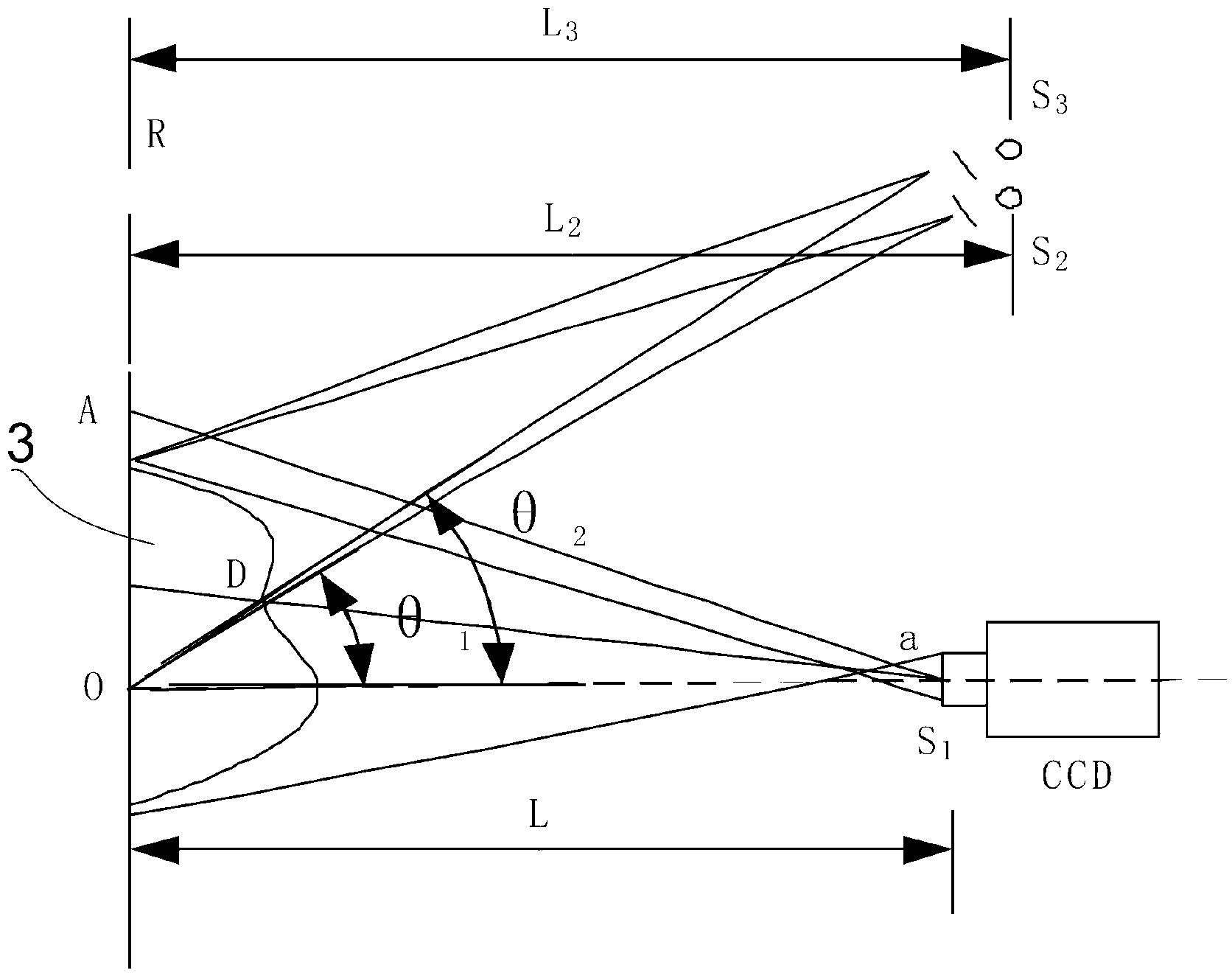

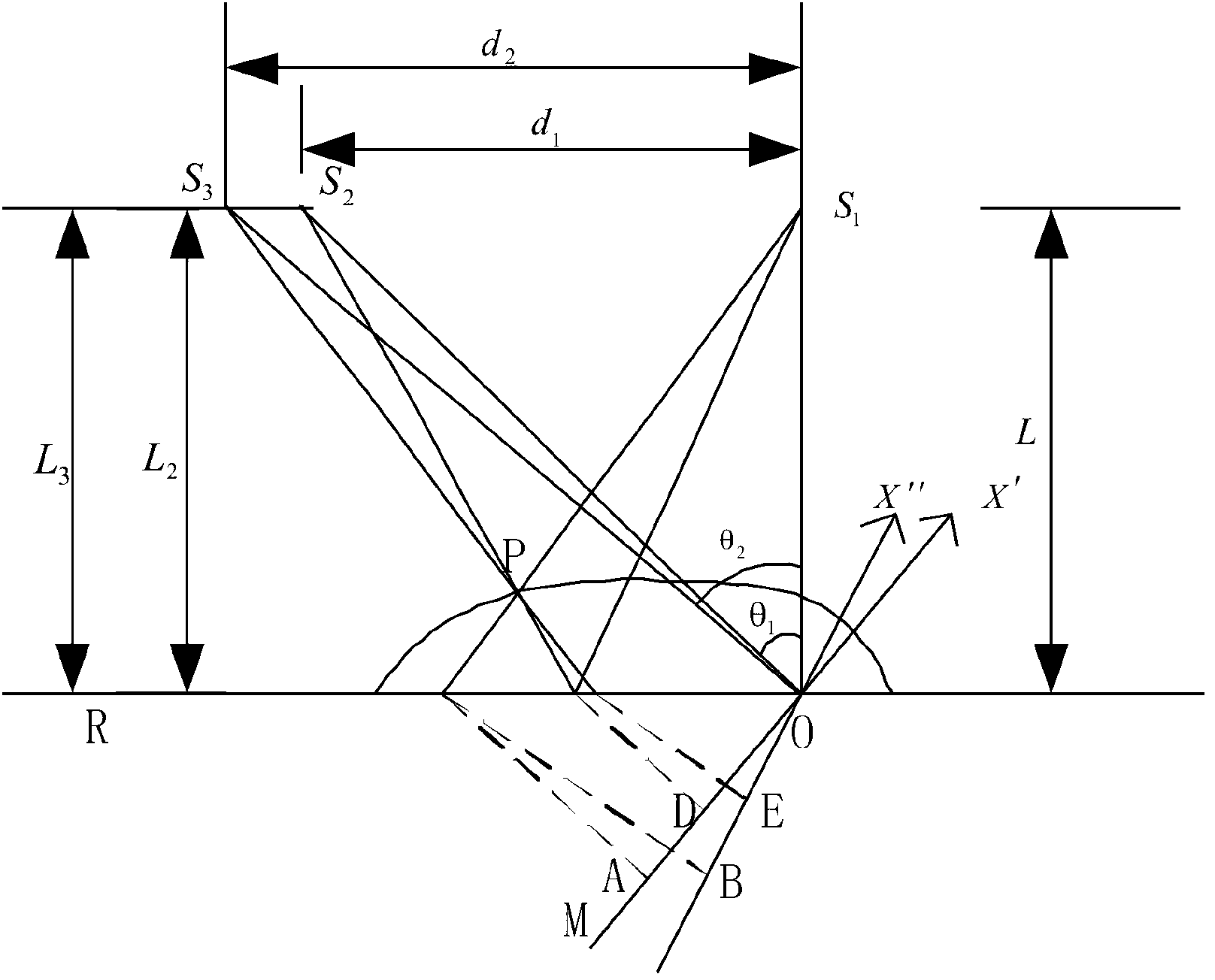

[0038]2. Measuring principle of small angle grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com