An overall yaw offshore floating wind farm

A wind farm and yaw technology, which is applied in wind power generation, wind motor combination, wind engine, etc., can solve the problems of large tower wind resistance, increased operating costs, and heavy workload at high altitude, so as to reduce personal safety accidents and reduce Maintenance cost and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be further described with reference to the accompanying drawings. These drawings are all simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

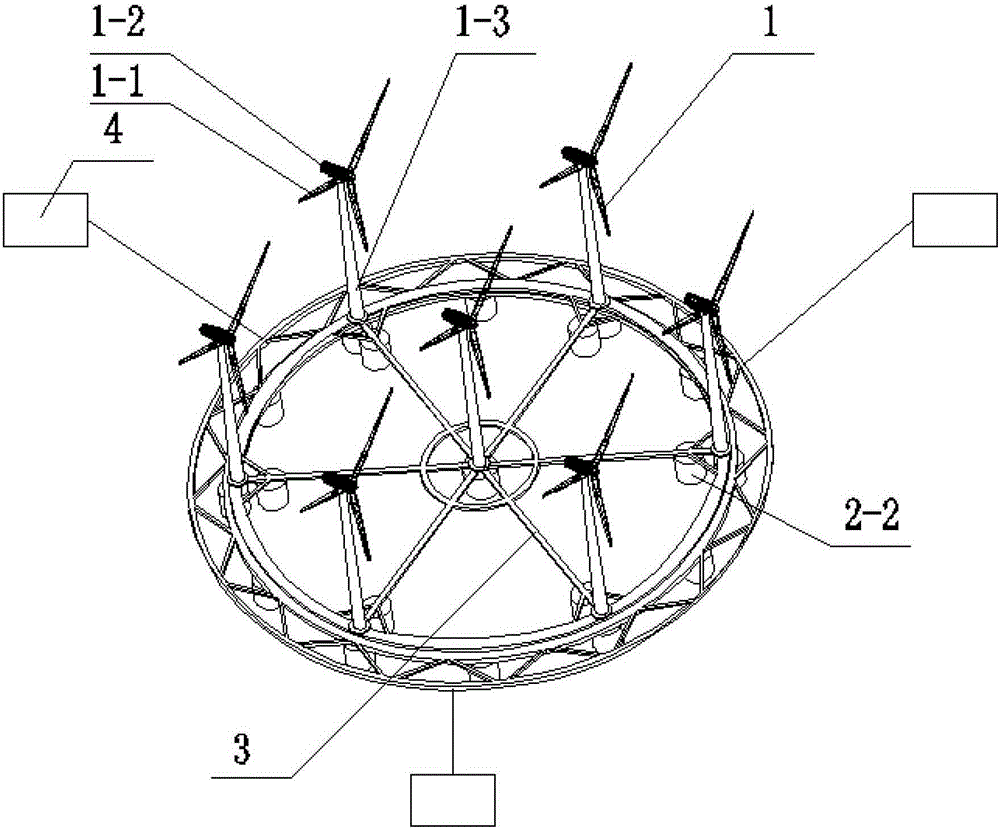

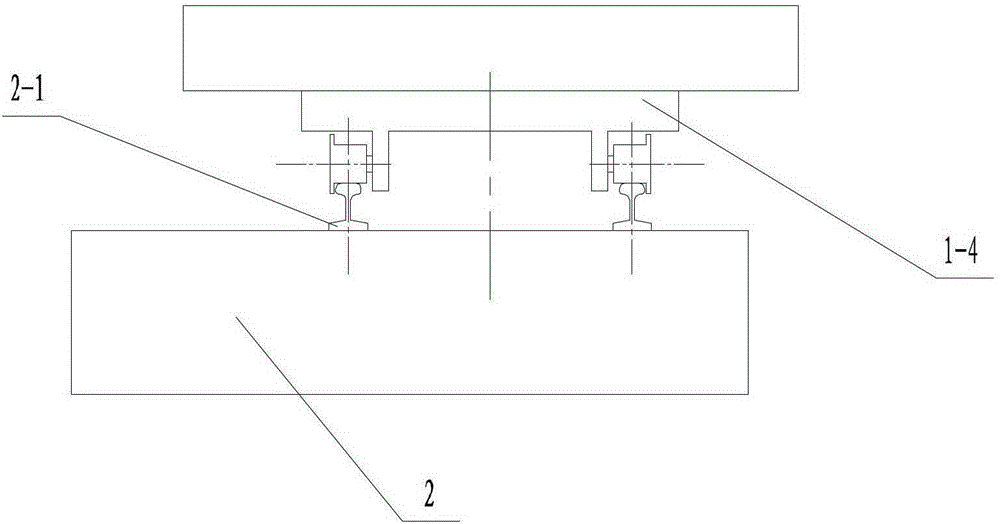

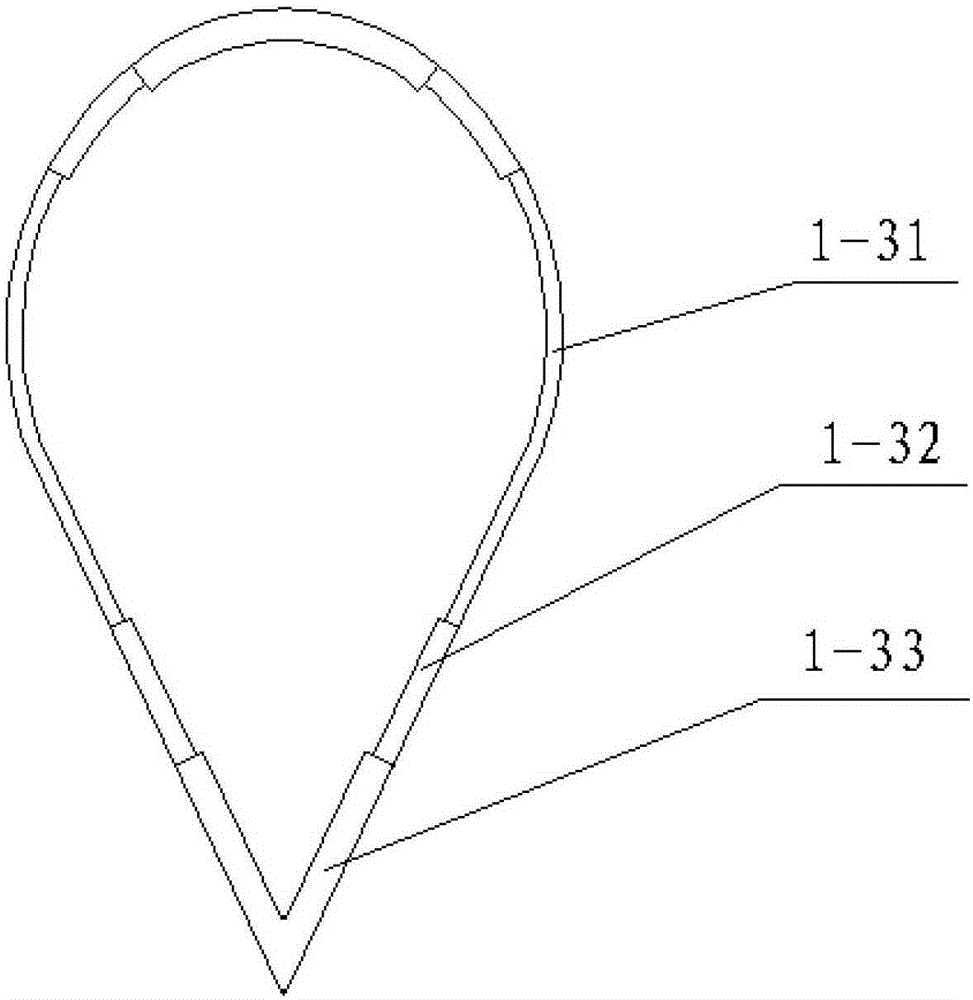

[0032] like figure 1 figure 2 As shown, an integral yaw type offshore floating wind farm has a plurality of yaw type wind turbines 1 and an annular floating platform 2, and each yaw type wind turbine 1 includes a wind wheel 1-1, a nacelle 1- 2. Tower 1-3, bogie 1-4, wind turbine 1-1 is installed on nacelle 1-2, nacelle 1-2 is fixed on tower 1-3, and the bottom of tower 1-3 is installed on the bogie 1-4 on. The bogies 1-4 of each yaw wind turbine 1 are mechanically connected by trusses or rods 3 . The annular floating platform 2 includes an annular track 2-1, a plurality of buoys 2-2 supporting the annular track, the annular track 2-1 is installed on the plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com