Using method of auxiliary ladder of steel tube tower

A technology for steel pipe towers and auxiliary ladders, applied in ladders, buildings, building structures, etc., can solve the problems of inaccessible bolt installation positions, ineffectiveness, time-consuming and labor-intensive, etc., and achieves reduction of labor intensity and safety risks. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

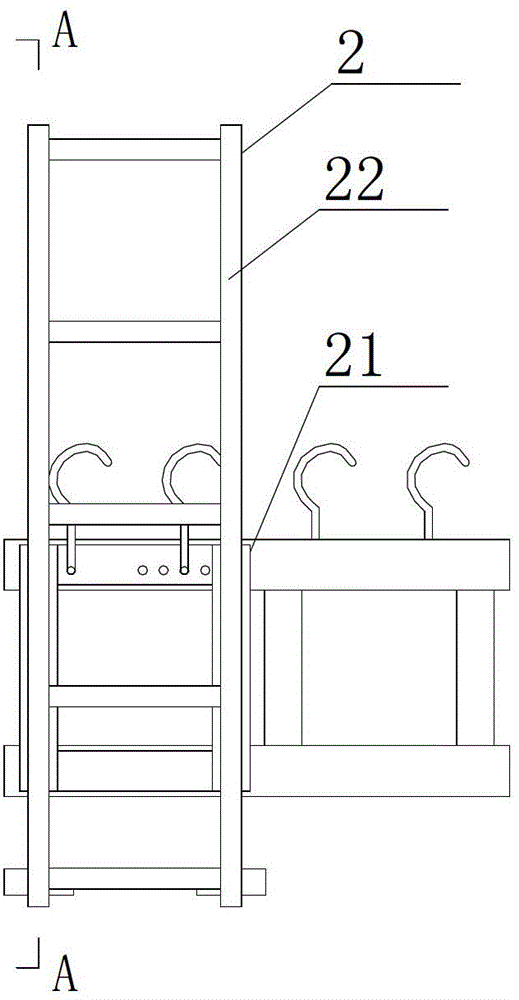

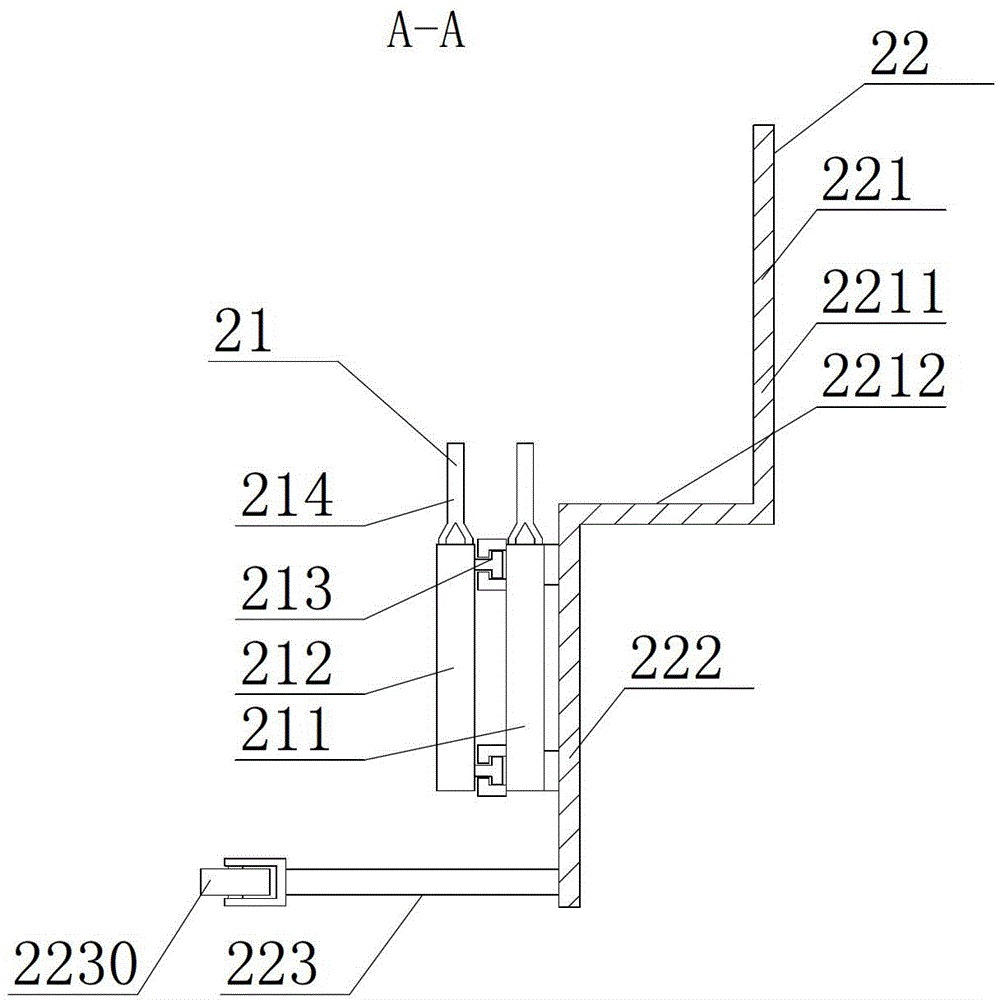

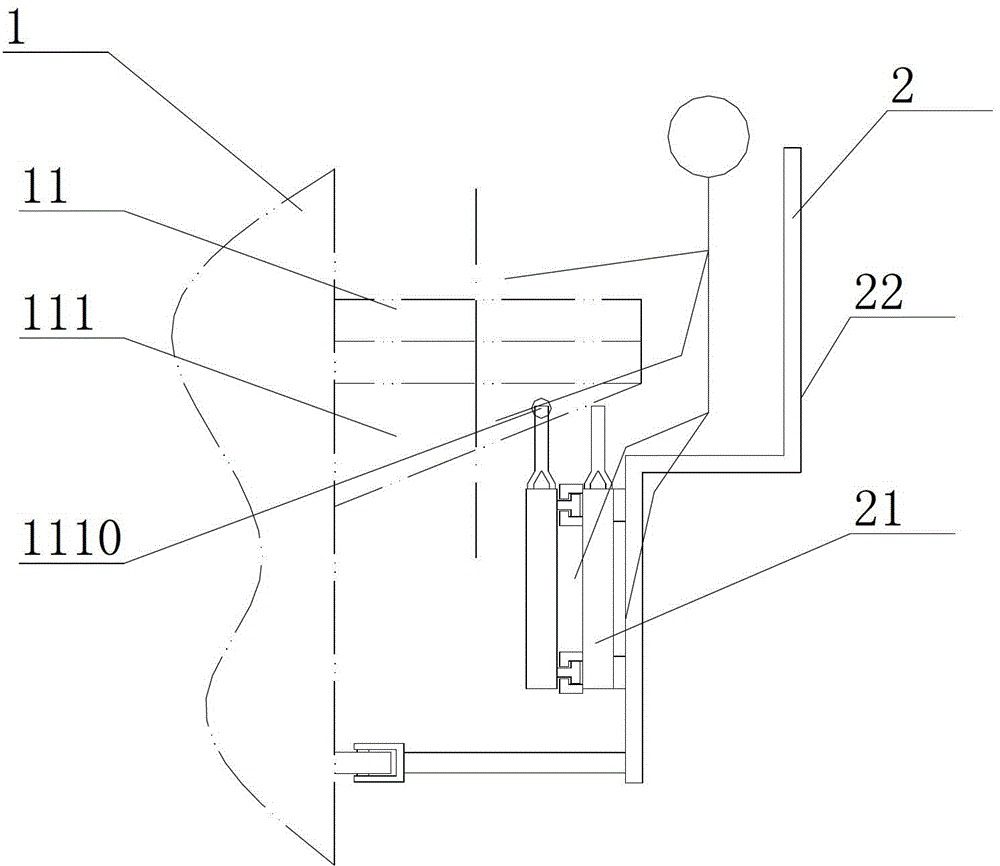

[0045] The present invention as Figure 1-14 As shown, the end face of the steel pipe tower 1 is provided with a flange 11, and the flange 11 is provided with a number of evenly distributed bolt mounting holes 110, and a reinforcing rib is provided below the adjacent mounting holes 110. 111, the reinforcing rib 111 is provided with eyelets 1110; the auxiliary ladder 2 includes a movable hanger 21 and a supporting ladder 22;

[0046] The movable hanger 21 includes a pair of hangers and at least one slide rail assembly 213; the top of the hanger is provided with at least a pair of hooks 214 (the mouth of the hook is provided with a lock), and a pair of the hangers 214 Rotation connection (can be hinged or connected by rotating pin) is on the top of the hanger; the slide rail assembly 213 is arranged between a pair of hangers, so that a pair of hangers are slidably connected by the slide rail assembly 213;

[0047] The pair of hangers is divided into hanger one 211 and hanger tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com