Plug of beverage vessel

A plug body and container technology, which is applied in the field of plug body of beverage containers, can solve problems such as insufficient pressure release, achieve the effect of suppressing splashing and reducing the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

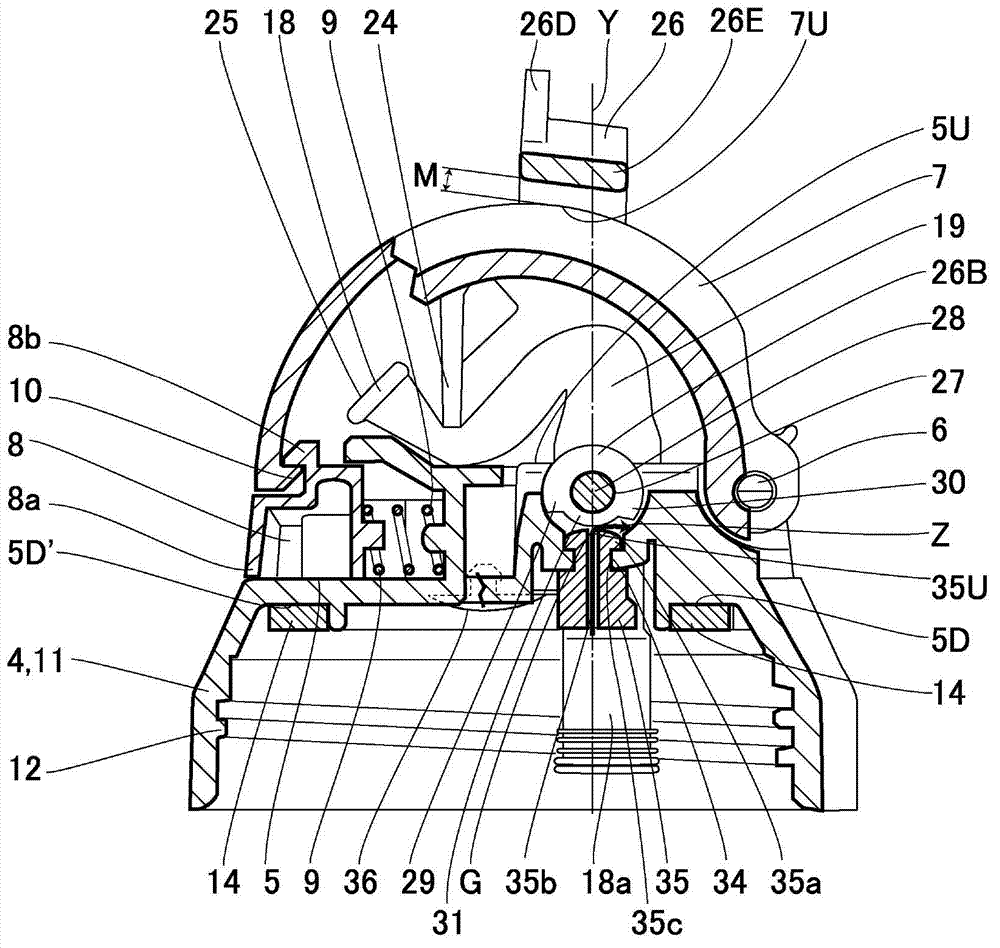

[0045] exist Figure 1-9Among them, symbol 1 is a portable beverage container related to the present invention as a whole, which includes: a metal vacuum-insulated container body 2; and a plug body 4 made of synthetic resin, which is covered on the upper part of the container body Container opening 3. In addition, the base end side of the substantially hemispherical cover 7 is rotatably rotated by the hinge shaft 6 provided as a left and right pair on the upper part of the rear end side of the first top part 5 . In shaft support state. Accordingly, the lid 7 is set in a state that can be moved up and down and freely opened and closed. Here, a lock mechanism 8 is provided on a side opposite to the hinge shaft 6, and the lock mechanism 8 can hold the lid 7 in a closed state by a hook-shaped locking portion 8b provided on the front side. The locking portion 8 b is integrally provided with an operating portion 8 a that exposes the front side and receives an outward bias via a s...

Embodiment 2

[0082] Other embodiments will be described below. The same parts as in the first embodiment are designated by the same symbols, and detailed description thereof will be omitted.

[0083] in such as Figure 10 to Figure 14 In the illustrated embodiment 2, the drinking spout unit 19 is inserted into the drinking spout mounting hole 20 which penetrates through the substantially central portion of the plug body 11 and is cylindrical in plan view. The lower part of the second top 5U. The upper portion of the suction pipe unit 19 is formed in a shape corresponding to the tapered upper mounting hole 44 . In addition, the suction pipe unit 19 further has a fitting concave portion 43 capable of fitting into the fitting convex portion 42 . Furthermore, the crimping lower portion 45 integrally formed with the straw unit 19 is pressed and abutted against the lower portion of the plug body 11 , thereby suppressing the straw unit 19 from being pulled out from the mouthpiece mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com