Full-automatic inner and outer bag packing machine capable of making outer bags for pesticides

A fully automatic, bag-making device technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve problems such as high cost, inability to meet mass production requirements, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

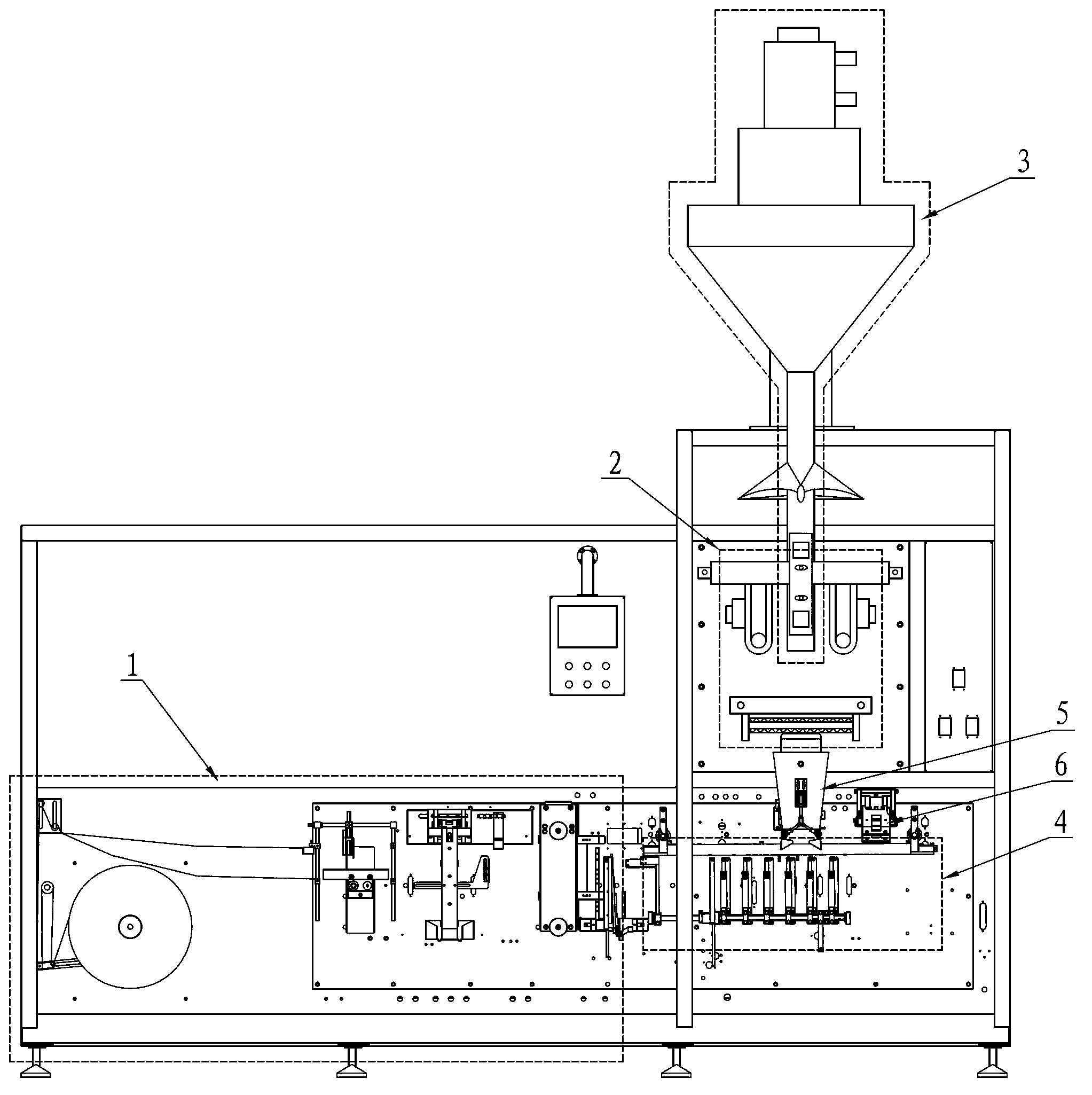

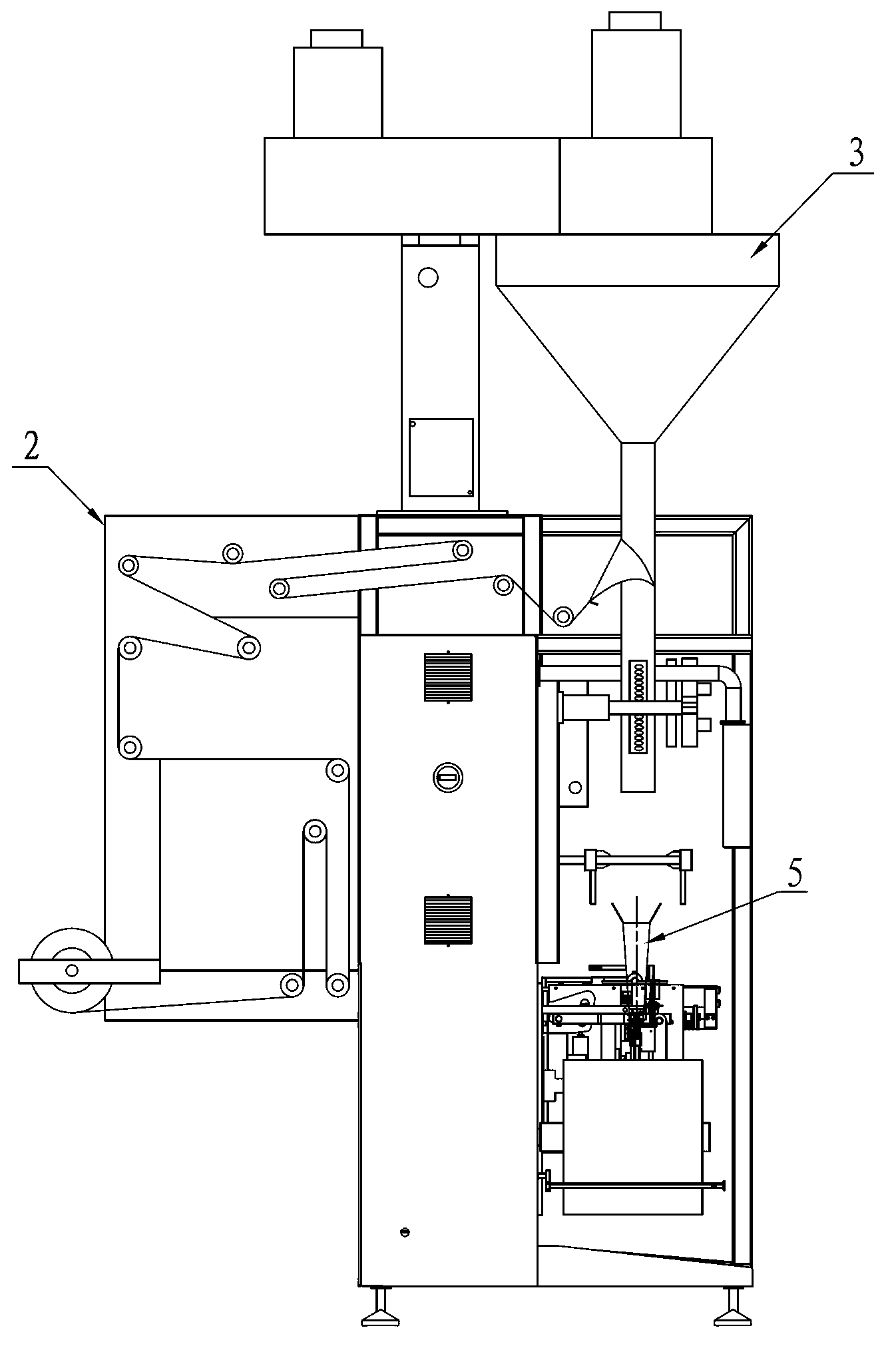

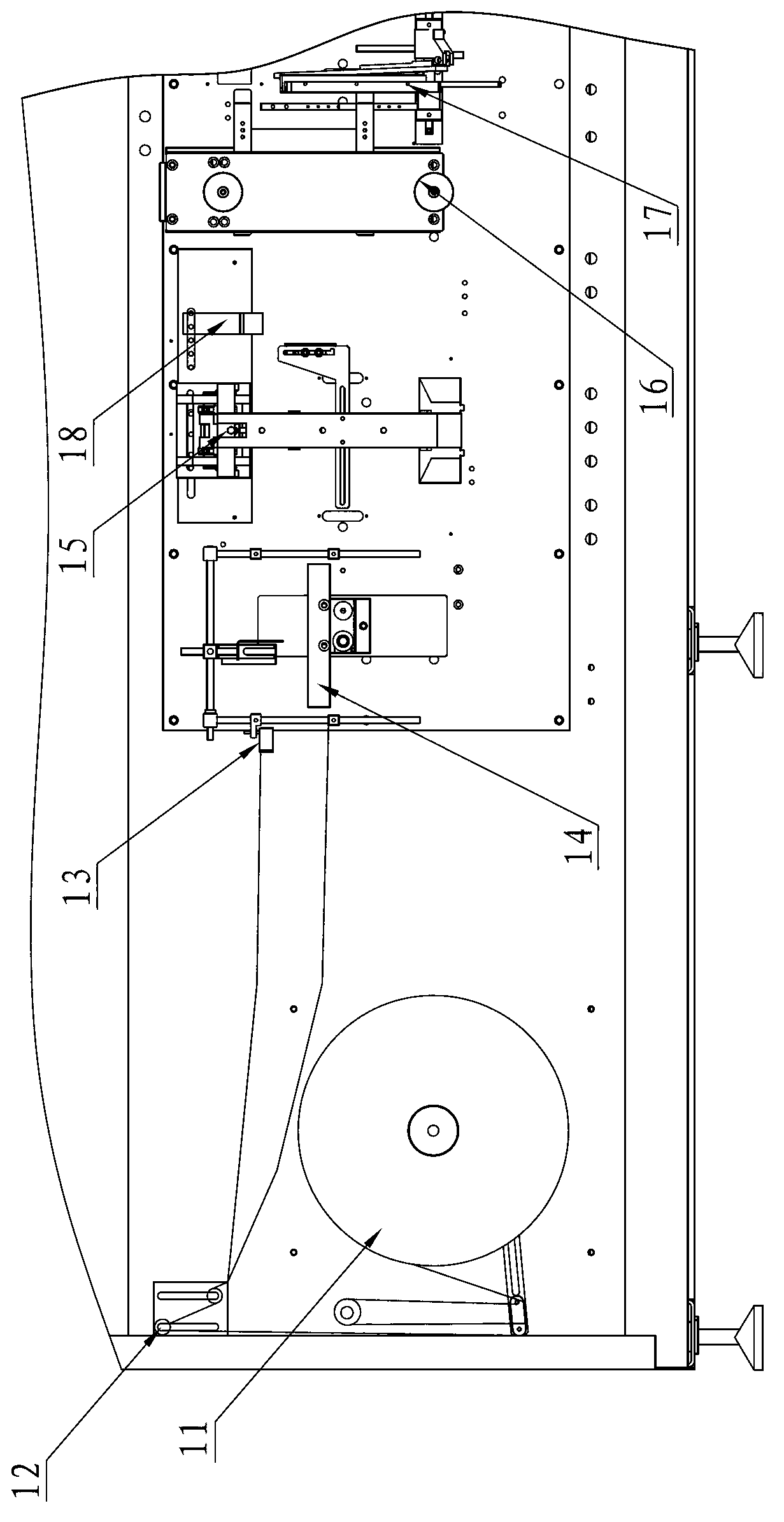

[0033] Example 1: An outer bag-making type automatic inner and outer bag packaging machine for pesticides, comprising a horizontal outer bag making device 1; a vertical inner bag making device 2; an inner bag material metering and filling device 3; a reciprocating outer bag traction Bag clamping device 4, inner bag quasi-injection outer bag device 5 and outer bag top sealing device 6; horizontal outer bag bag making device 1 and reciprocating outer bag traction bag clamping device 4 are linearly distributed along the horizontal direction; inner bag materials The metering and filling device 3 and the vertical inner bag making device 2 are distributed collinearly along the vertical direction, and the inner bag material metering and filling device 3 and the vertical inner bag making device 2 are collinearly compounded, and the inner bag is accurately fed to the outer bag device 5 Set below the inner bag material metering and filling device 3; the horizontal outer bag bag making de...

Embodiment 2

[0034] Embodiment 2: The difference from Embodiment 1 is that the inner bag material metering filling device 3, in this example, the inner bag material metering filling device 3 is a single-head liquid filling unit, a single-head liquid filling unit The middle liquid filling nozzle is arranged in the inner bag mold core 24 in the vertical inner bag bag making device 2 .

[0035] There are many embodiments of the present invention, and the inner bag material metering and filling device 3 and the inner bag quasi-throwing outer bag device 5 also have many other functional substitution structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com