Method and device for quickly replacing oil gas pipe section

A replacement method and pipe section technology, which is applied in auxiliary devices, measuring devices, surveying and navigation, etc., can solve the problems of oil and gas pipeline explosion, low work efficiency, and low precision of pipe sections, and achieve the effect of safe replacement and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

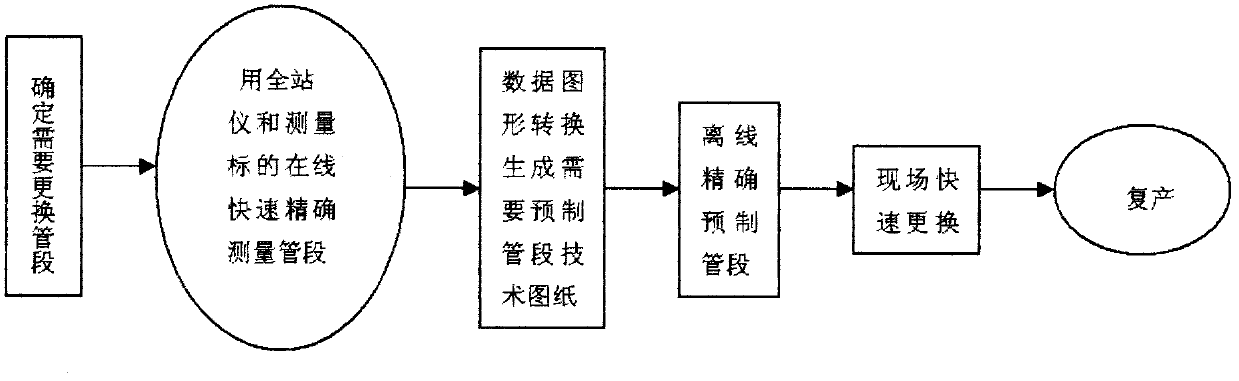

[0032] figure 1 It is a block diagram of the process route for rapid replacement of oil and gas pipeline sections, which consists of determining the replacement pipeline section, laser online rapid and precise measurement of the pipeline section, data-graphic conversion, off-line accurate prefabricated replacement pipeline section, on-site quick replacement of the pipeline section, pipeline pressure test and leak test, etc.

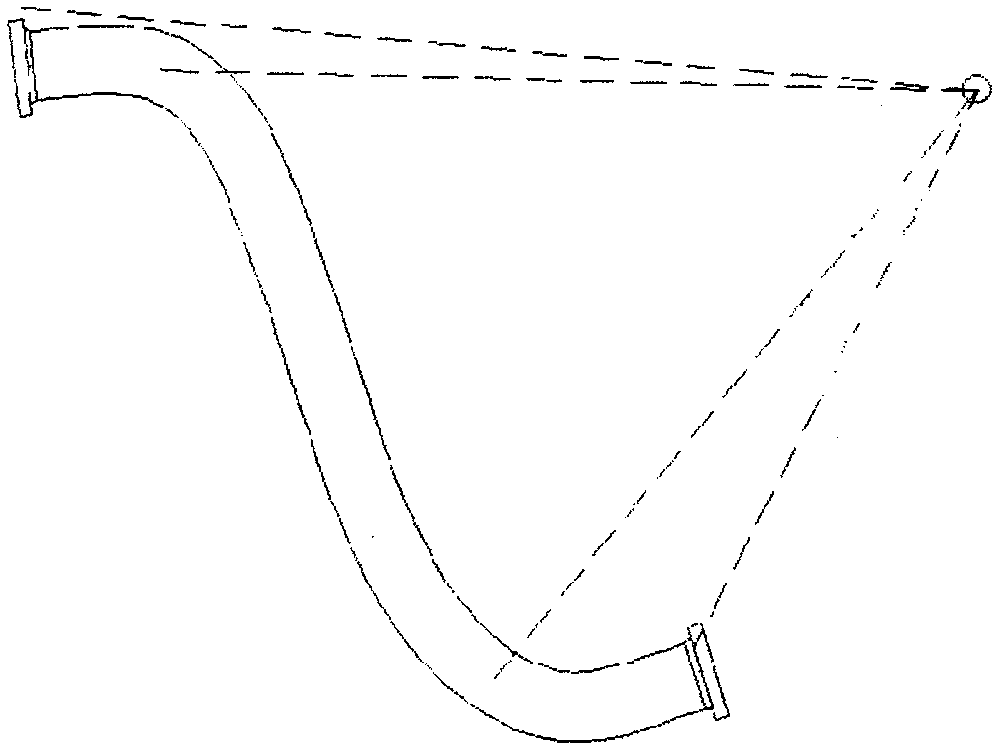

[0033] figure 2 , 3 Schematic diagram of the measurement of the spatial geometry parameters of the pipe section for the laser total station and the measurement target. figure 2 It is a schematic diagram of measuring the orientation of a pipe section with a total station. After placing the total station at a position where it can measure the overall picture of the pipe section, fix it with a measuring tripod and position it, and select at least 4 points on the pipe section to be measured that can reflect the obvious geometric characteristics of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com