TiO2 nano particle/TiO2 nanotube array and application thereof

A nanotube array and nanoparticle technology, which is applied in chemical/physical processes, surface reaction electrolytic coatings, physical/chemical process catalysts, etc. To achieve the effect of improving the photoelectric catalytic degradation efficiency, increasing the light source irradiation, and improving the photoelectric catalytic degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

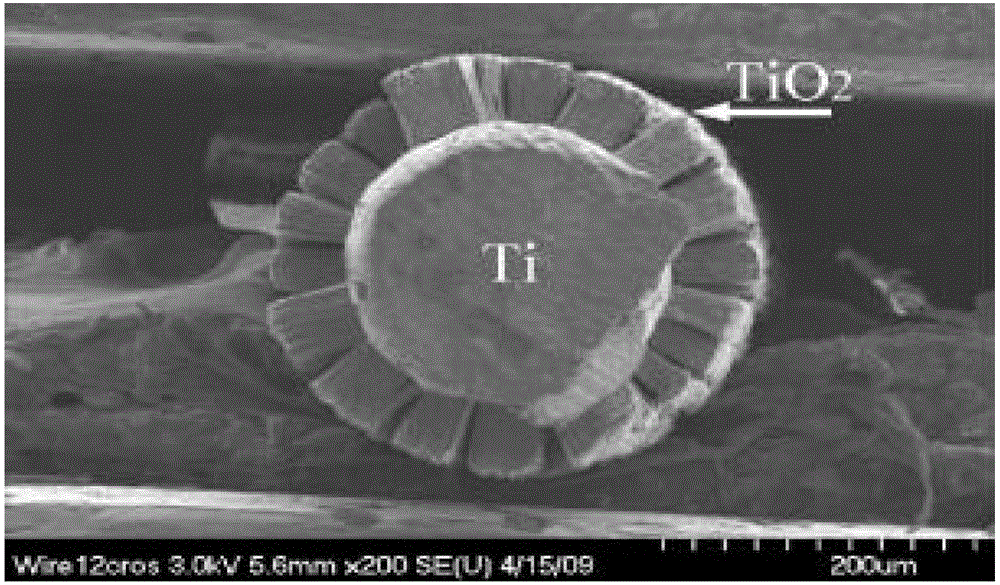

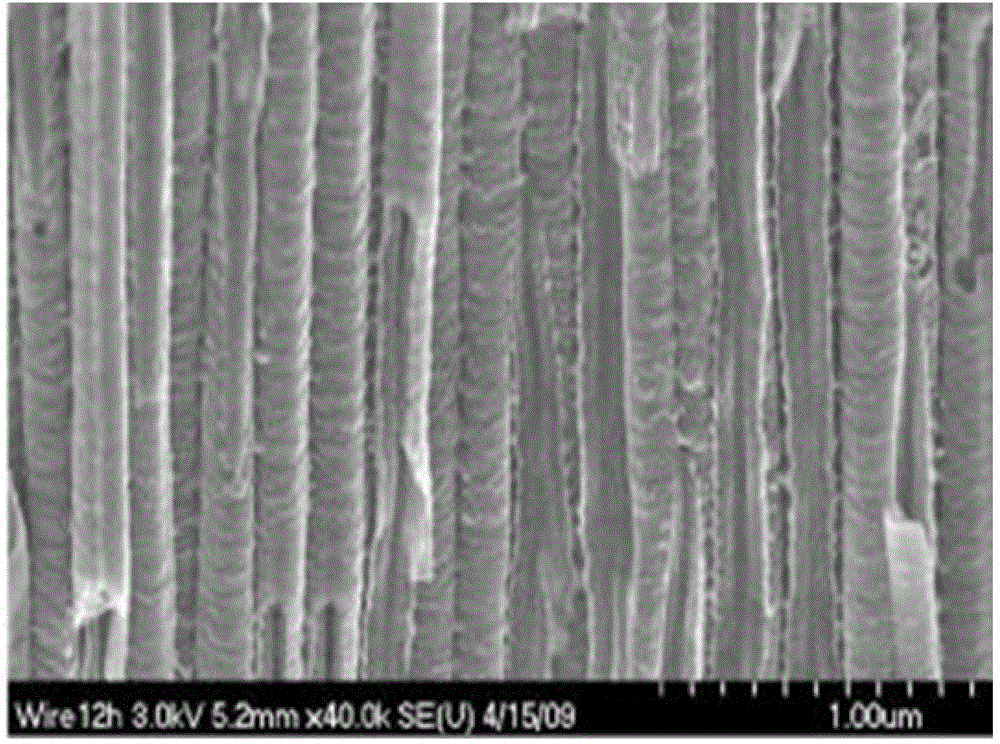

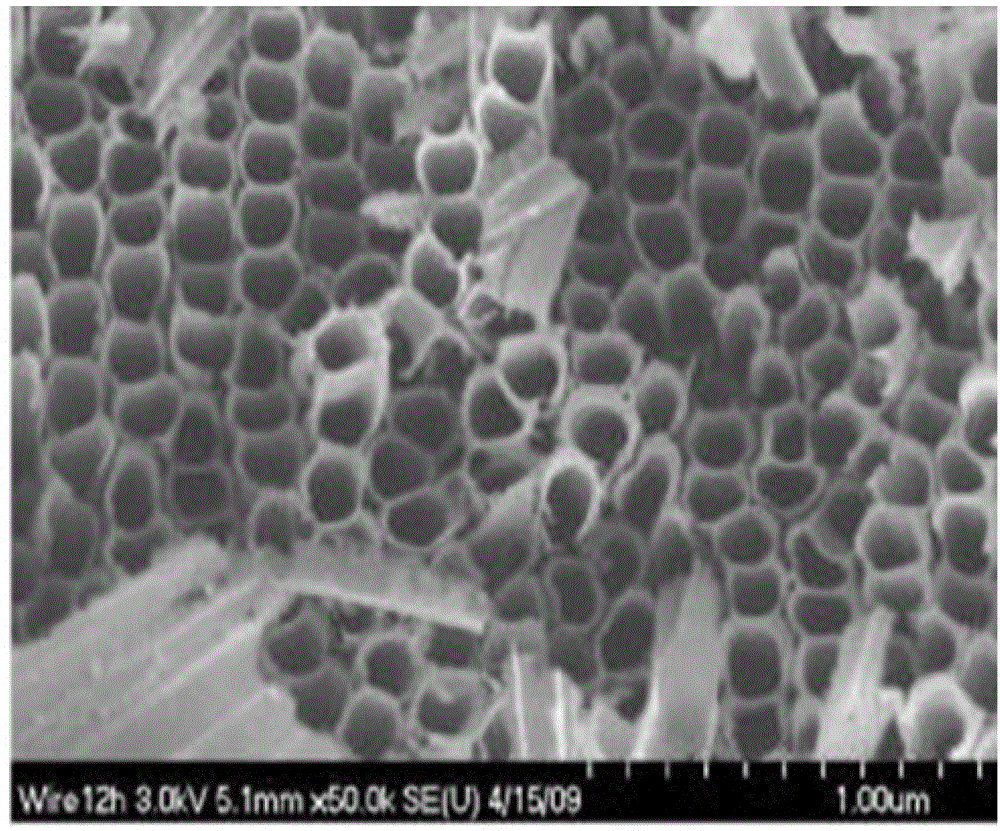

[0042] Example 1TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0043] (1) Pretreatment of titanium wire

[0044] Take a metal titanium wire with a diameter of 2cm and a length of 30cm. After polishing it smoothly, it is ultrasonicated in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, it is polished in a polishing solution for 1 minute, and then deionized water. Clean and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0045] (2) TiO 2 Fabrication of nanotube arrays

[0046] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 20cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 2cm; the program boost method is adopted Raise to 70V, anodize for 3 hours; rinse the titanium wire w...

Embodiment 2

[0060] Example 2TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0061] (1) Pretreatment of titanium wire

[0062] Take a metal titanium wire with a diameter of 0.02cm and a length of 25cm. After polishing it smoothly, ultrasonically clean it in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, polish it in a polishing solution for 2 minutes, and then deionize it. Wash with water and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0063] (2) TiO 2 Fabrication of nanotube arrays

[0064] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 15cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 3cm; the programmed voltage increase method is adopted Raise to 90V, anodize for 2 hours; rin...

Embodiment 3

[0074] Example 3TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0075] (1) Pretreatment of titanium wire

[0076] Take a metal titanium wire with a diameter of 3cm and a length of 25cm. After polishing it smoothly, it is ultrasonicated in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, it is polished in a polishing solution for 3 minutes, and then deionized water. Clean and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0077] (2) TiO 2 Fabrication of nanotube arrays

[0078] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 20 cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 0.7 cm; the voltage is increased by a program After the reaction, rinse the titanium wire with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com