Chromatism-free patterning carbon nanotube transparent conductive film and preparation method thereof

A technology of transparent conductive film and carbon nanotube film, which is applied to conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve the problems of low light transmittance, low yield, and inability to use conductive layers. Achieve high light transmittance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

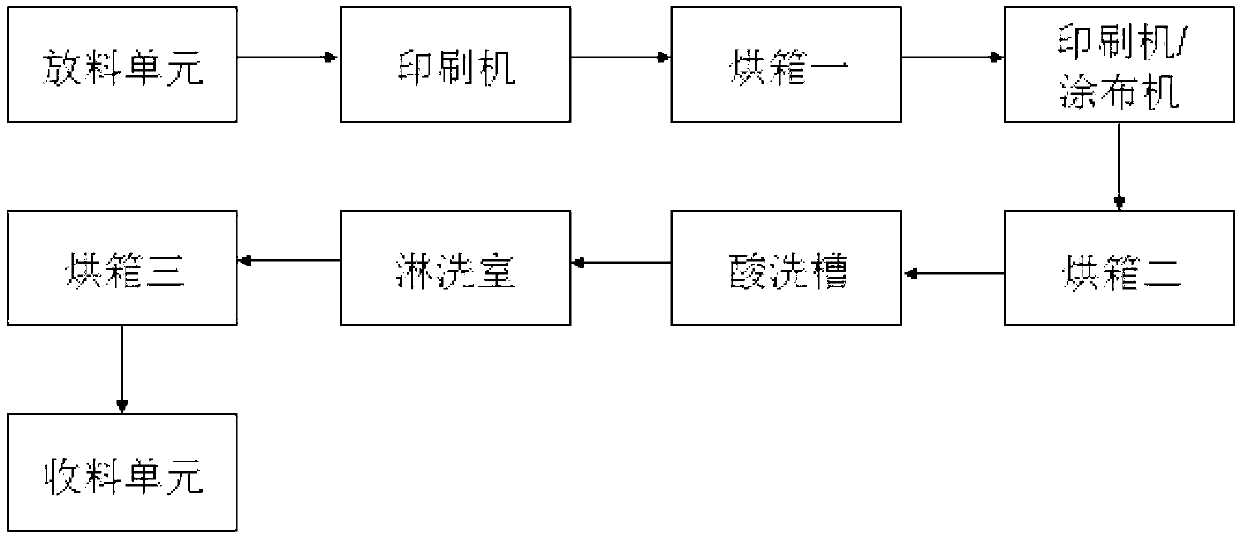

[0054] As one of the better specific application solutions, refer to figure 1 , the preparation method may specifically include the following steps:

[0055] (1) Use pigments to adjust the color of the hydrophobic ink;

[0056] (2) Print the toned hydrophobic ink onto the surface of the flexible transparent substrate 4 by flexographic printing to form an insulating area and form a set negative pattern structure, and dry in an oven to form a patterned insulating material layer 1;

[0057] (3) Apply the carbon nanotube dispersion 2 on the surface of the substrate (including the insulating layer area and the electrode pattern area) by using the method of dimple coating, and use the principle of oil-water separation to automatically form the required electrode pattern, and then dry it in an oven Forming a transparent conductive layer 3 (patterned carbon nanotube film);

[0058] (4) Pickling to remove impurities such as surfactants remaining on the surface of the carbon nanotube ...

Embodiment 1

[0072] Example 1 Add an appropriate amount of carbon black MD-1808 to simethicone oil containing a curing aid, stir well, and pour it into the ink tank of a flexographic printing machine; the prepared carbon nanotube dispersion ( Concentration is 0.5wt%) and joins in the ink tank of dimple coater; Start the machine button, adjust the mechanical speed to be 5m / min, adjust the unwinding tension to be 5kg, and the winding tension to be 5.5kg, adjust the drying of oven one The temperature is 120°C, and the drying temperature of the second and third ovens is adjusted to 100°C; when the temperature of the oven rises to the set temperature, press the start button, and under the traction of the guide film, the PET (ethylene glycol phthalate) film Walking process can refer to figure 2 . First, the silicone oil is printed on the PET film by a flexographic printing machine to form a set negative pattern. The printed PET film enters the oven 1 and is dried under hot air at 120°C, and th...

Embodiment 2

[0073] Example 2 Add an appropriate amount of carbon black MD-1808 to the methyl chlorophenyl silicone oil containing curing aids, stir well, and pour it into the ink tank of the flexographic printing machine; disperse the configured carbon nanotubes Liquid (concentration is 0.5wt%) joins in the ink tank of gravure printing machine; Start the machine button, adjust the mechanical speed to be 5m / min, adjust the unwinding tension to be 5kg, and the winding tension to be 5.5kg, adjust the drying of oven one The temperature is 120°C, and the drying temperature of the second and third ovens is adjusted to 100°C; when the temperature of the oven rises to the set temperature, press the start button, and under the traction of the guide film, the PET (ethylene glycol phthalate) film Walking process can also refer to figure 2 . First, the silicone oil is printed on the PET film by a flexographic printing machine, and a set negative pattern is formed. The printed PET enters the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com