A maintenance control device for a locomotive auxiliary motor equipment maintenance line

An auxiliary motor and equipment maintenance technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of cluttered management status, low coordination efficiency, no locomotive auxiliary motor maintenance line system control, etc., to achieve resource allocation. The effect of high efficiency and high coordination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

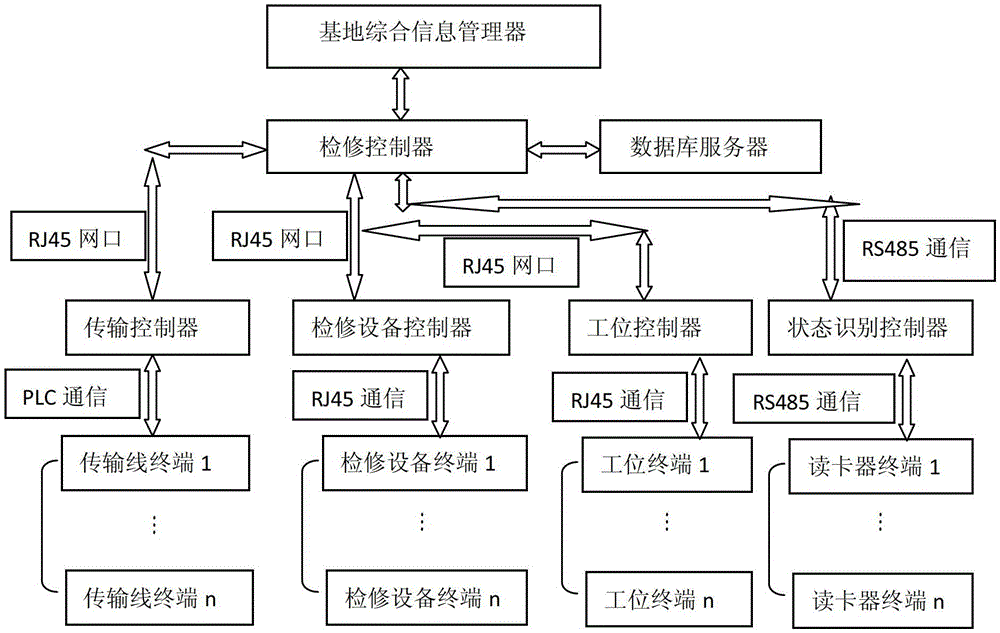

[0020] combine Figure 1~3 The first embodiment of the maintenance control device for the maintenance line of the auxiliary motor equipment of the locomotive according to the present invention is described as follows.

[0021] A maintenance control device for a maintenance line of an auxiliary motor equipment of a locomotive, comprising: an information terminal device for collecting information on a maintenance line terminal of an auxiliary motor equipment and issuing control instructions; a device for receiving and analyzing information from the information terminal equipment and issuing control instructions Maintenance controller; the signal transmission end of the information terminal equipment is connected with the signal transmission end of the maintenance controller.

[0022] The maintenance controller also includes the function of an application server to display and classify the information of equipment maintenance line terminals.

[0023] In this embodiment, the info...

Embodiment 2

[0026] combine Figure 1~3 The second embodiment of the maintenance control device for the maintenance line of the auxiliary motor equipment of the locomotive according to the present invention is described as follows.

[0027] A maintenance control device for a maintenance line of an auxiliary motor equipment of a locomotive, comprising: an information terminal device for collecting information on a maintenance line terminal of an auxiliary motor equipment and issuing control instructions; a device for receiving and analyzing information from the information terminal equipment and issuing control instructions Maintenance controller; the signal transmission end of the information terminal equipment is connected with the signal transmission end of the maintenance controller.

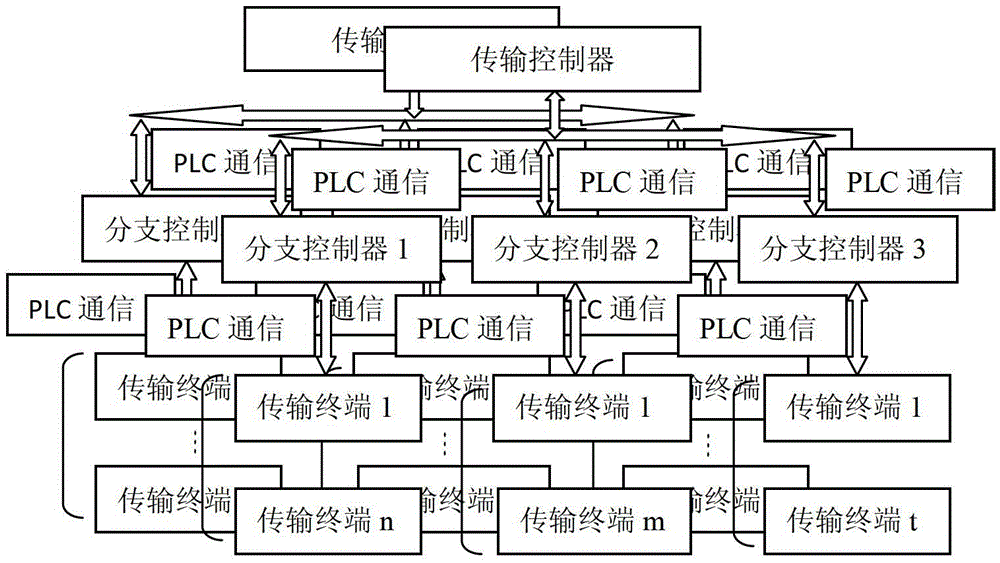

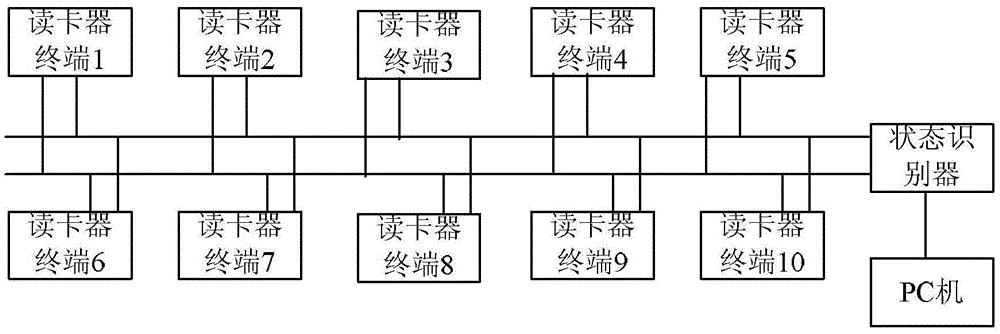

[0028] In this embodiment, the information terminal equipment includes: a transmission controller for collecting information on transmission line terminals and issuing control instructions; an inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com