Microwave power sensor with multi-cantilever structure

A microwave power and sensor technology, applied in the direction of electric power measurement by thermal method, can solve the problem of microwave signal consumption, etc., to achieve the effects of improved compatibility and repeatability, determinable error range, and wide operating frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

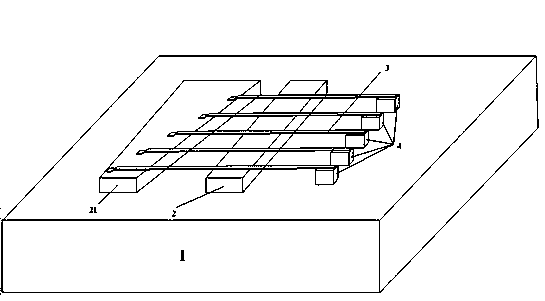

[0015] The multi-cantilever beam structure microwave power sensor of the present invention uses GaAs or Si material as the substrate 1, is provided with the microstrip line 2 on the substrate 1, connects several mutually parallel, different lengths and microstrip lines on the cantilever beam anchor region 21 The cantilever beams 3 perpendicular to the strip line 2, the group of cantilever beams 3 are suspended above the microstrip line 2, and the pressure welding fast 4 is placed under the free ends of the cantilever beams 3.

[0016] The manufacturing process of the microwave power sensor with the multi-cantilever beam structure is compatible with the standard Si process or GaAs process.

[0017] The multi-cantilever beam structure microwave power sensor is different from the previous online microwave power sensor based on MEMS technology. This structure uses cantilever beams of different lengths suspended above the microstrip line to induce microwave power and generate displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com