A Curvature Sensor of Multi-Double-End Fixed Beam Structure

A curvature sensor and a fixed beam technology, applied in the field of curvature sensors, can solve the problems of inability to measure the precise value of the geometric shape, inability to measure online, and large volume, and achieve the effects of convenient and easy detection, excellent mechanical properties, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

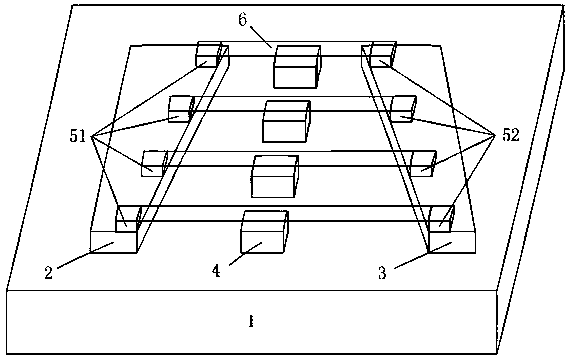

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention provides a curvature sensor based on a plurality of double-end fixed beam structures, the curvature sensor includes a flexible substrate 1, trapezoidal metal 2, 3, metal contact block 4, double-end fixed beam anchor area 51, 52. Double-ended fixed support beam 6, the number of trapezoidal metals 2 and 3 is two, the trapezoidal metal 23 and the metal contact block 4 are arranged on the surface of the flexible substrate 1, and the two trapezoidal metals 2 and 3 are placed on the metal contact block 4 On both sides, double-end fixed beam anchorage areas 51 and 52 are respectively placed on the trapezoidal metal 23, and a plurality of parallel and suspended double-end fixed beam anchorage areas 51 and 52 are arranged above the metal contact block 4. Support beams 6, multiple double-ended fixed-supported beams 6 have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com