Method for synchronous measurements on dynamic and static elastic parameters of rocks

An elastic parameter, synchronous measurement technology, used in the application of stable tension/pressure to test the strength of materials, and the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc. problem, to achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

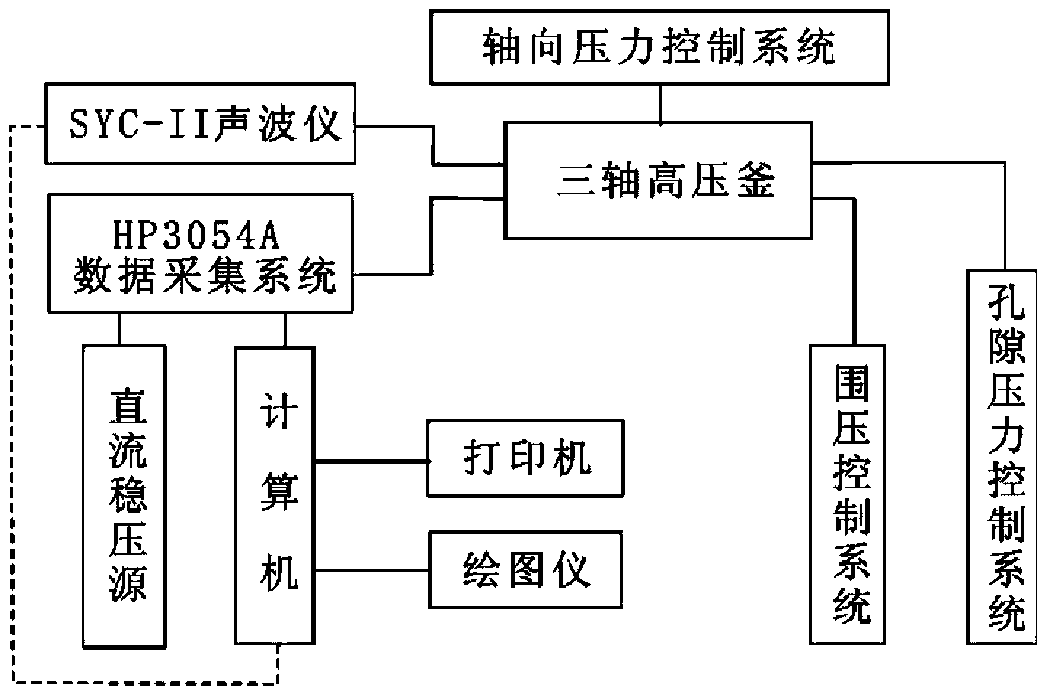

[0039] refer to figure 1 , which shows a schematic structural diagram of a rock triaxial compression test device, which may specifically include the following system:

[0040] Triaxial autoclave 10;

[0041] Axial pressure control system 11;

[0042] Confining pressure control system 12;

[0043] Pore pressure control system 13;

[0044] Computer acquisition and control system 14;

[0045] The axial pressure control system 11 , confining pressure control system 12 , pore pressure control system 13 , and computer acquisition and control system 14 are all connected to the triaxial autoclave 10 .

[0046] Such as figure 1 As shown, in a specific implementation, the computer acquisition and control system 14 may include an aco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com