Auxiliary management system for coal mining gas

A management system and gas technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of gas monitoring system such as missed detection in empty shifts, inability to perform real-time monitoring, poor monitoring effect, etc., and achieve good monitoring effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

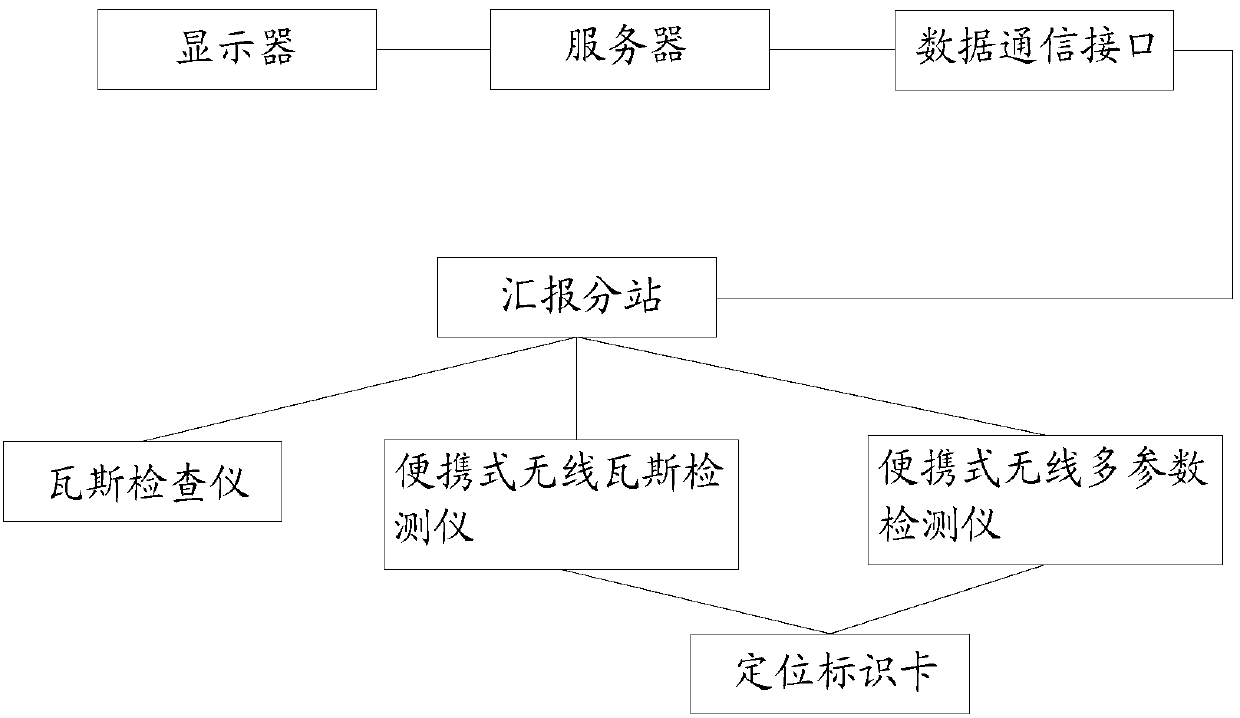

[0015] Such as figure 1 As shown, the coal mine gas auxiliary management system provided by the present invention includes a server located on the ground, a reporting substation located underground, a positioning identification card placed in a key gas management area, a gas inspection instrument carried by a full-time gas inspector, and operation management personnel. Portable wireless gas detector and portable wireless multi-parameter detector.

[0016] The location identification card has a built-in address code used to identify a specific detection location. In this embodiment, the built-in address code of the location identification card is a unique 16-digit hexadecimal code. The reporting substation is equipped with metal keyboard input or touch screen input. One end of the server is connected to a display that displays real-time data parameters, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com