A track beam emergency repair and replacement system

A technology for rail beams and steel box beams is applied in the field of emergency repair and replacement systems for rail beams to achieve the effect of improving blindness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

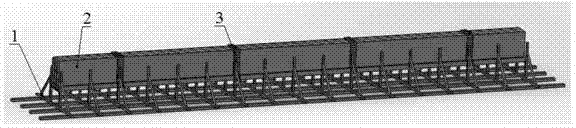

[0024] Embodiment 1 Replacement of damaged track beams by using prefabricated steel box girders

[0025] In this embodiment, the single-span span L of the emergency track beam structure is 10m to 50m; the segment length L1 of the steel box girder is 1m to 50m; the curvature radius R of the steel box girder is 50m to ∞m; the number of types of prefabricated steel box girder segments is N1 is 2 to 60; the number of linear types of connecting plates N2 is 2 to 60, the number n1 of each type of steel box girder segment is 1 to 50, and the number n2 of each type of steel box girder connecting plates is 1 to 200.

[0026] Specific use steps:

[0027] Step 1 Emergency repair and replacement of the command center. If any track beam in the straddle monorail transit system is damaged, the emergency repair and replacement command center will issue an emergency response to coordinate the evaluation and removal of the damaged track beam and the emergency track beam material library of var...

Embodiment 2

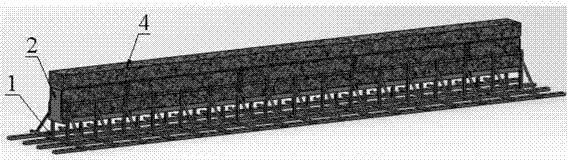

[0034] Example 2 The damaged track beam is replaced by a steel box-concrete composite structure

[0035] In this embodiment, the single-span span L of the emergency track beam structure is 10m to 50m; the segment length L1 of the steel box girder is 1m to 50m; the curvature radius R of the steel box girder is 50m to ∞m; the number of types of prefabricated steel box girder segments is N1 is 2 to 60; the linear type number N2 of the connecting plate is 2 to 60, the number n1 of each type of steel box girder segment is 1 to 50, and the number n2 of each type of steel box girder connecting plate is 1 to 200; both sides of the steel box girder are outsourced The thickness h1 of the concrete is 10 mm to 850 mm; the thickness h2 of the concrete on the top of the steel box girder is 10 mm to 2000 mm.

[0036] Specific use steps:

[0037] Step 1 Emergency repair and replacement of the command center. If any track beam in the straddle monorail transit system is damaged, the emergency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com