Pneumatic-vacuum combined type washing machine

A combined, washing machine technology, applied in the field of washing machines, can solve problems such as low washing ratio and entanglement of clothes, and achieve the effects of increasing water flow intensity, preventing wrinkles and solving difficulty in drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

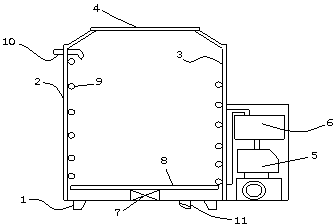

[0013] see figure 1 Among them, an air pressure and vacuum combined washing machine, including a machine foot 1, a casing 2, an inner cylinder 3, a sealing cover 4, an air compressor 5, an air storage tank 6, a bearing 7, a rotating disk 8, a nozzle 9, and a vacuum pump, It is characterized in that: the lower end of the housing 2 is fixed with the organic foot 1, the inner cylinder 3 is vertically placed in the housing 2, the upper part of the inner cylinder 3 is a cylinder mouth ring, the cylinder mouth ring is equipped with a sealing cover 4, and the lower part of the inner cylinder 3 is provided with a rotating disk 8 , the rotating disk 8 is placed in the bearing 7 at the bottom of the inner cylinder 3, and nozzles 9 arranged in different directions are distributed on the cylinder wall of the inner cylinder 3, and the nozzles 9 are connected to the gas storage tank 6 through a pipeline, and valves are installed on the pipeline , the air storage tank 6 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com