Swinging washing machine

A washing machine and swing-type technology, applied in the field of washing machines, can solve the problems of entanglement of clothes and low washing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

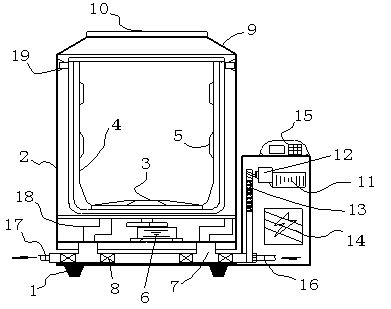

[0012] See figure 1 Among them, a swing type washing machine is mainly composed of a swing bucket, a base, and a swing mechanism. It is characterized in that the lower end of the swing bucket is connected to the base through a movable joint, and a swing mechanism is arranged between the swing bucket and the base to form a swing bucket. The horizontal axis is tilted back and forth with respect to the vertical line. At least one movable joint is arranged at the lower end of the swing bucket to connect with the base. The movable joint is connected by a hollow shaft 7 in the middle to form a three-way connection with two hollow shafts 7 The ends are erected in the two-end bearings 8 arranged on the base as a movable support point, and the through pipe is fixed at the lower end of the swing bucket.

[0013] The through pipe directly communicates with the inside of the housing 2 of the swinging bucket through a water pipe. One or both ends of the hollow shaft 7 are further co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com