Sinking type fabric draw-off mechanism of full-forming intelligent flat knitting machine

A technology of pulling mechanism and flat knitting machine, which is applied in the direction of weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of uneven product, limited swing range, floating yarn, etc., so as to ensure the quality of weaving and knitting , prevent the effect of yarn floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

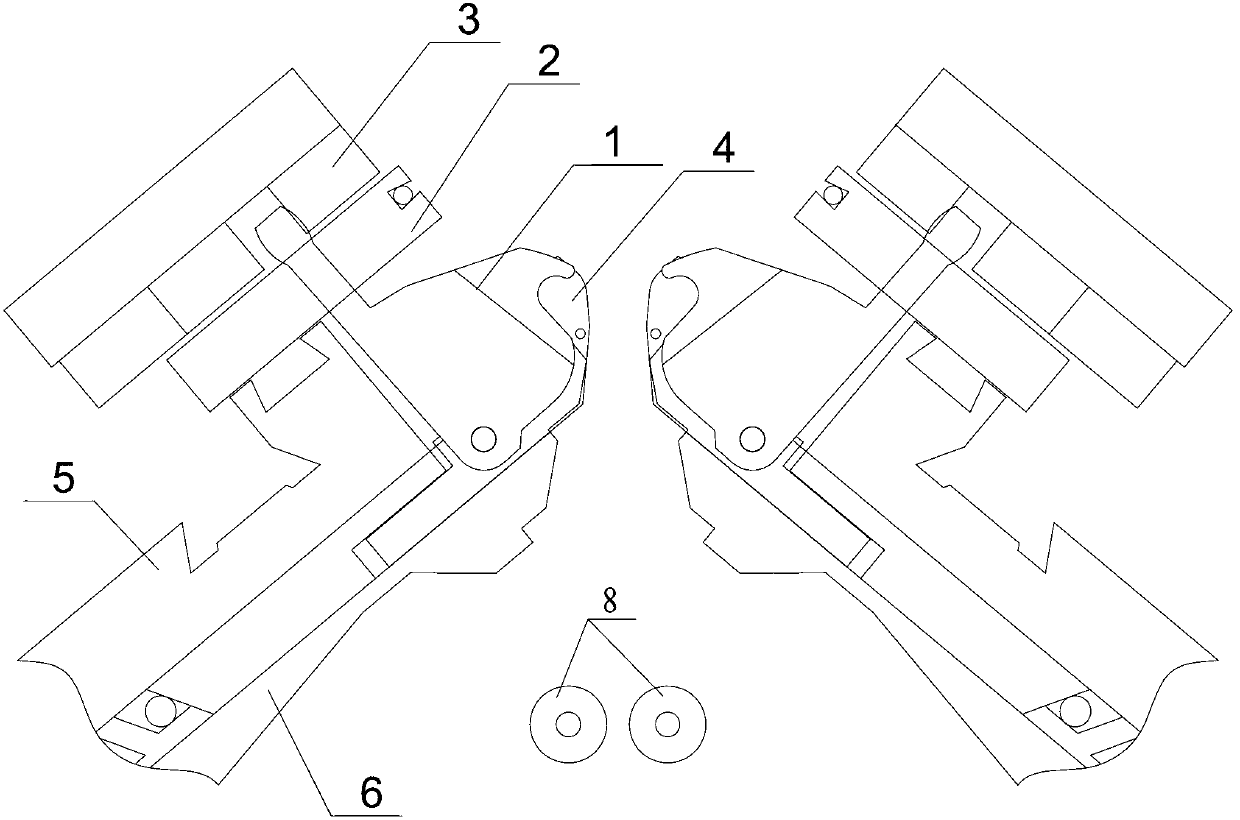

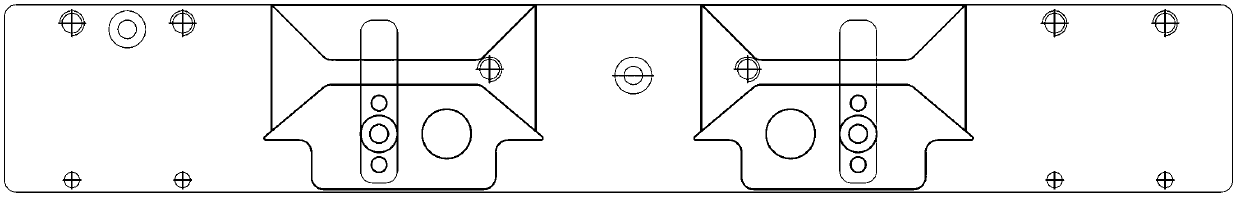

[0028] Such as figure 1 As shown, the subsidence type fabric pulling mechanism of the fully formed intelligent flat knitting machine of the present invention includes a subsidence mechanism installed on the two needle beds respectively and a pair of winding rollers 8 below the needle beds, and the subsidence mechanism includes One sinker 7 and the Shengke triangle 3 that cooperates with the playing bell 7-1 of this sinker.

[0029] The sinker is hinged on the small needle plate 2 (the hinge port 2-1 of the small needle plate is as Figure 14 shown), while the sinker of a conventional flat knitting machine is hinged on the needle bed 6; the distance between the sinker’s lifting bell 7-1 and the hinge point 7-2 ( Figure 16 Shown by the line segment C in the middle), which is equal to the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com