An amphoteric acrylic resin leather tanning agent

An acrylic resin, acrylic technology, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, tanning treatment, etc. The effect of dosage, excellent water solubility, and excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

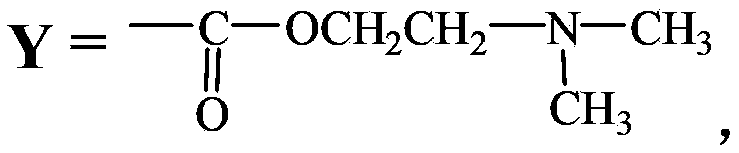

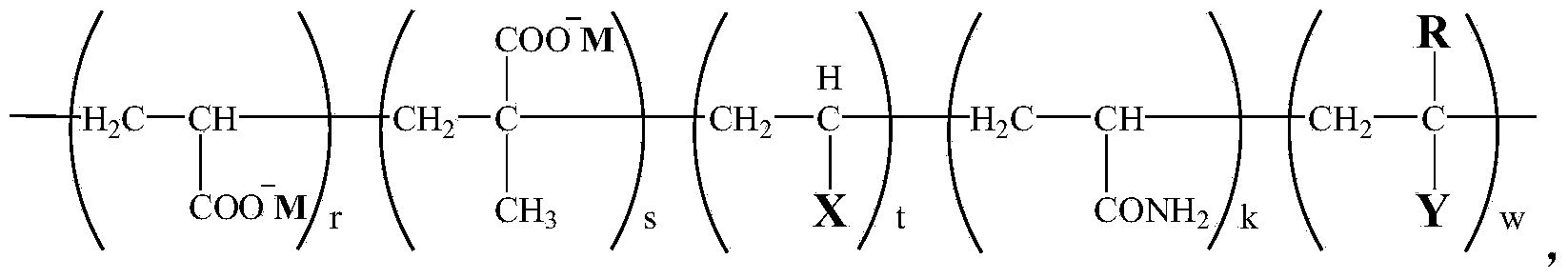

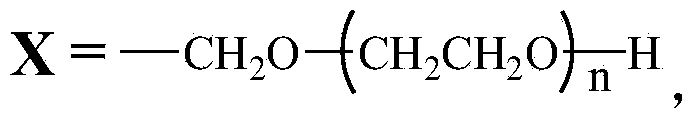

[0021] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0022] 1) Dissolve 12.0 grams of acrylic acid and 12.0 grams of methacrylic acid in 59.4 grams of deionized water, stir at 10-20 ° C, add 40.8 grams of 30% sodium hydroxide aqueous solution dropwise in 30 minutes, and then add it in 10 React at ~20°C for 15 minutes to obtain monomer aqueous solution A;

[0023] 6.0 grams of dimethylaminoethyl acrylate, 18.0 grams of acrylamide, and 3.0 grams of ethylene glycol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0024] Make the initiator aqueous solution C of mass concentration 5% with 2.4 grams of ammonium persulfate;

[0025] 2) Add 12.0 grams of allyl polyether APEG-500 and 25.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and add dropwise within 2.5-3.0 hours Step 1) The prepared mon...

Embodiment 2

[0027] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0028] 1) Dissolve 15.0 grams of acrylic acid and 15.0 grams of methacrylic acid in 44.6 grams of deionized water, stir at 10-20°C, add 71.4 grams of potassium hydroxide aqueous solution with a mass concentration of 30% within 1 hour. React at 10-20°C for 15 minutes to obtain monomer aqueous solution A;

[0029] 12.0 grams of dimethylaminoethyl methacrylate, 12.0 grams of acrylamide, and 4.0 grams of isopropanol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0030] Make the initiator aqueous solution C of mass concentration 5% with 3.6 grams of ammonium persulfate;

[0031] 2) Add 6.0 grams of allyl polyether APEG-700 and 15.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and drop them simultaneously within 2.5-3.0 hours Step 1) The...

Embodiment 3

[0033] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0034] 1) Dissolve 6.0 grams of acrylic acid and 6.0 grams of methacrylic acid in 55.8 grams of deionized water, stir at 10-20°C, add 29.1 grams of monoethanolamine aqueous solution with a mass concentration of 30% dropwise within 30 minutes, and after the addition is completed, in 10 React at ~20°C for 15 minutes to obtain monomer aqueous solution A;

[0035] 18.0 grams of dimethylaminoethyl acrylate, 12.0 grams of acrylamide, and 5.0 grams of ethylene glycol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0036] Make the initiator aqueous solution C of mass concentration 5% with 1.8 gram of ammonium persulfate;

[0037] 2) Add 18.0 grams of allyl polyether APEG-1000 and 40.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and add drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com