Device for preparing clean liquid for clean acetylene gas in chlor-alkali system and method thereof

An acetylene gas, clean technology, applied in the direction of absorption purification/separation, organic chemistry, etc., can solve the problems of high cost of liquid caustic soda and chlorine gas, weak market of concentrated sodium hypochlorite solution, high sales pressure and environmental protection pressure, etc., to achieve good utilization and reduce Costs, the effect of reducing sales pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

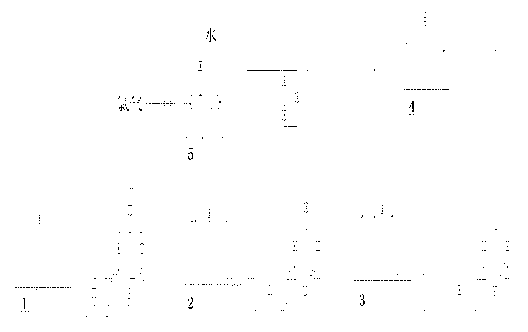

[0016] Such as figure 1 As shown, a kind of equipment for preparing clean liquid used in cleaning acetylene gas in a chlor-alkali system, which includes a concentrated sodium hypochlorite storage tank 1, a concentrated sodium hypochlorite buffer tank 2, a dilute sodium hypochlorite storage tank 3, a dilute sodium hypochlorite high level tank 4 and Venturi 5. A lift pump is arranged between the concentrated sodium hypochlorite storage tank 1 , the concentrated sodium hypochlorite buffer tank 2 , the dilute sodium hypochlorite storage tank 3 and the dilute sodium hypochlorite elevated tank 4 . A flow meter is arranged between the dilute sodium hypochlorite storage tank 3 and the venturi 5 .

[0017] A method for preparing a clear liquid for cleaning acetylene gas in a chlor-alkali system, comprising the steps of:

[0018] a, the concentrated sodium hypochlorite solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com