Efficiency optimizing method of master-slave type multi-motor driving system

A multi-motor drive, efficiency optimization technology, applied in the direction of motor, electric vehicle, control drive, etc., can solve the problem of low comprehensive efficiency, and achieve the effect of extending the driving range, improving economy and power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

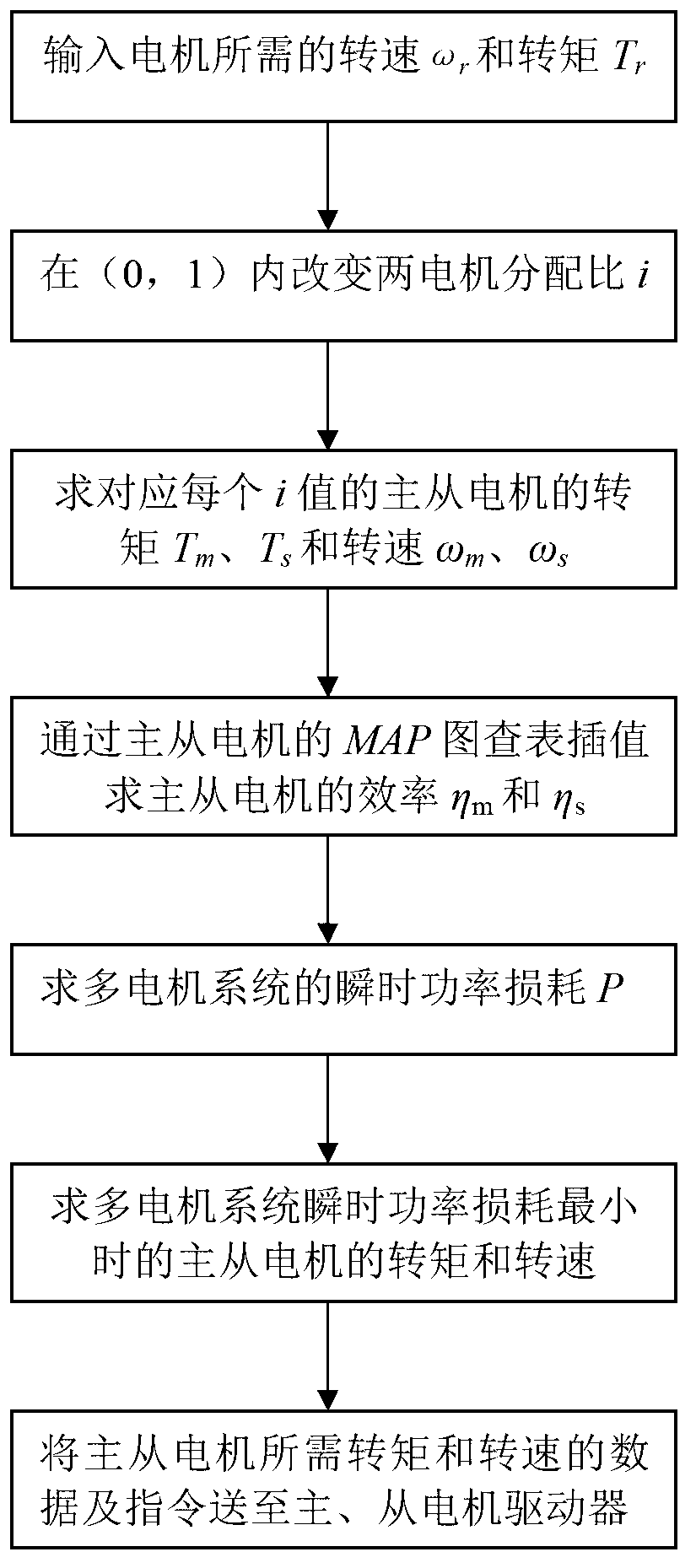

[0038] The present invention will be further described below according to the accompanying drawings and specific embodiments.

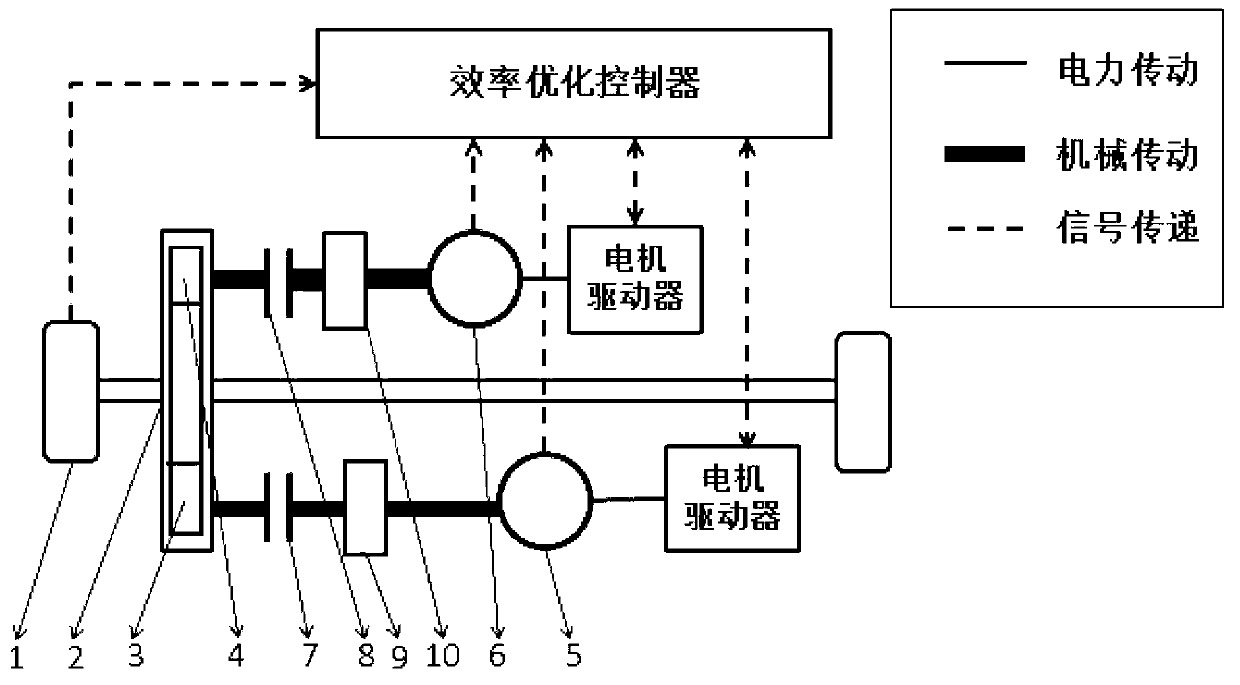

[0039] figure 1 It is a composition block diagram of the master-slave multi-motor drive system involved in the present invention, including: master motor (5), slave motor (6), gear reduction mechanism (2), clutch 1 (7), clutch 2 (8), joint Coupling 1 (9), coupling 2 (10), and motor control system.

[0040] The main motor (5) is a high-power motor, the slave motor (6) is a low-power motor, the main motor (5), the clutch 1 (7), the coupling 1 (9) and the power input end 1 of the gear reduction mechanism (3) Fixedly installed together; the motor (6), clutch 2 (8), coupling and the power input end 2 (4) of the gear reduction mechanism are fixedly installed together; after the two motors are decelerated and increased by the gear reduction mechanism , to output the power from the output terminal to the rear wheels (1).

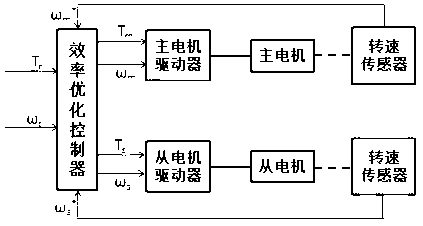

[0041] The block diagram of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com