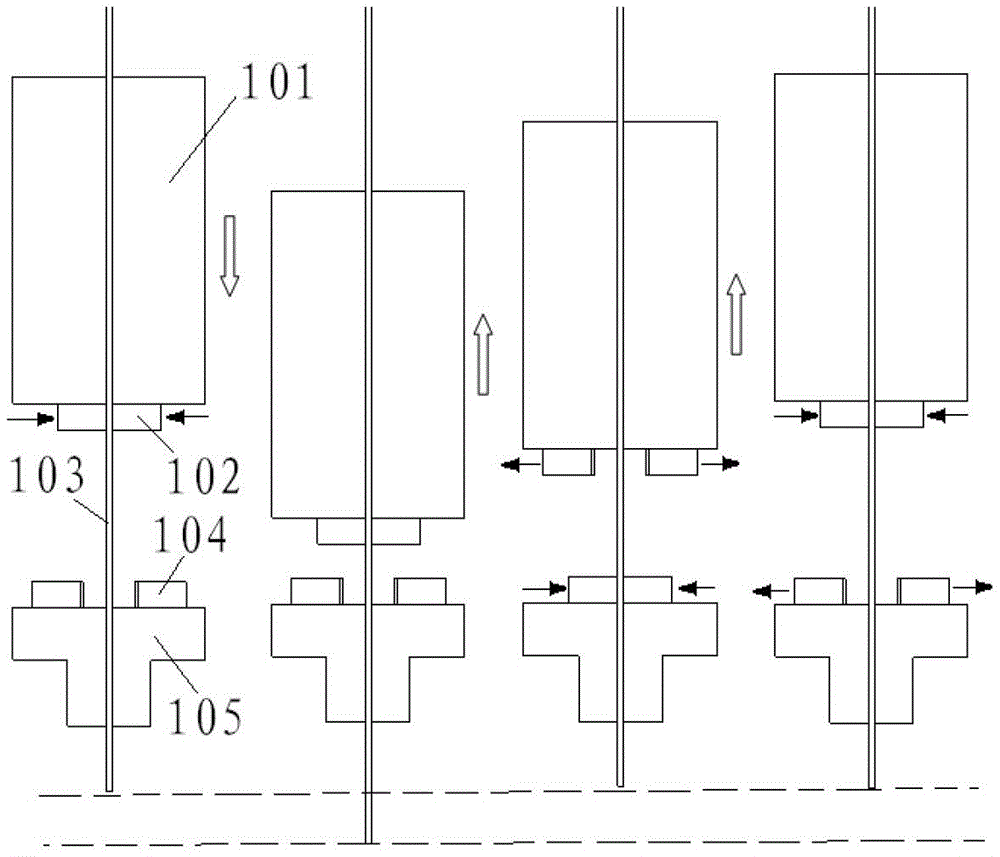

Self-clamping dynamic sealing device capable of feeding electrode wires in wriggled mode

A technology of dynamic sealing and electrode wire, which is applied to the sealing of the engine, accessories, engine components, etc., can solve the problems of increasing the weight of the overall device, unable to discharge debris well, and the size of the device is large, and achieves simple structure and manufacturing. The effect of low cost and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

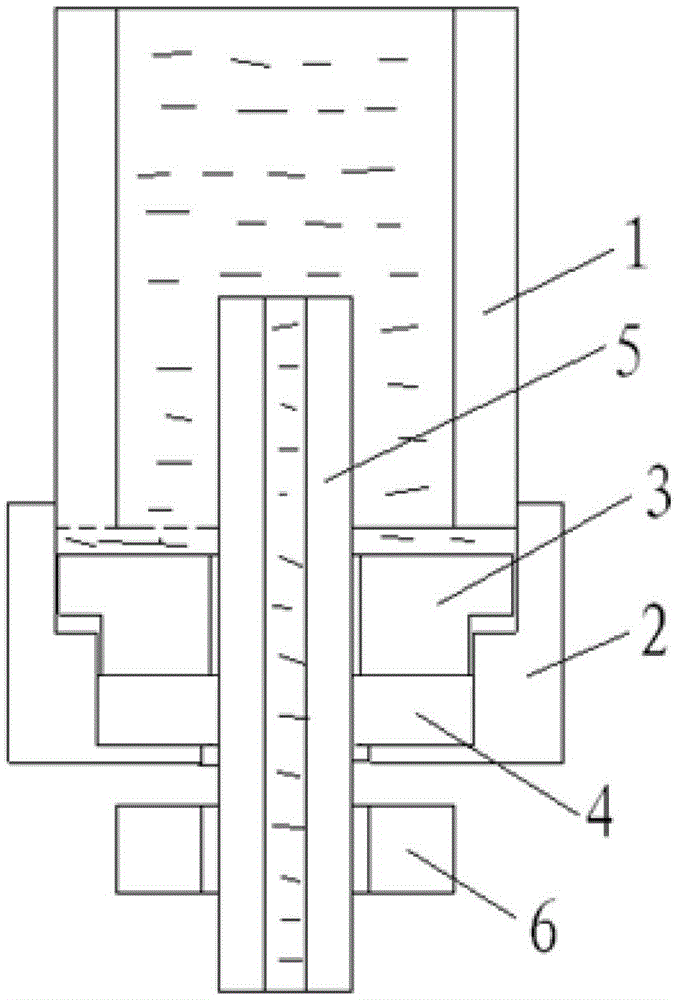

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] Such as figure 2 As shown, a self-clamping dynamic sealing device for peristaltic feeding electrode wire, including a hollow motor shaft 1, a gland 2, a hard sealing ring 3 and a soft sealing ring 4;

[0032] The bottom end of the hollow motor shaft 1 and the upper end of the gland 2 are connected by thread sealing, and an inner cavity is formed inside the gland 2, and the hard seal ring 3 and the soft seal ring 4 are filled in the gland 2 from top to bottom. In the inner cavity; the hollow electrode wire 5 passes through the hollow main shaft 1 of the motor, the hard sealing ring 3, the soft sealing ring 4 and the gland 2; there is a gap between the upper end surface of the hard sealing ring 3 and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com