Automatic nano material filtering machine and use method thereof

A technology of nanomaterials and filters, applied in separation methods, filtration and separation, chemical instruments and methods, etc., can solve the needs of mass production of nanomaterials, affect the performance of nanomaterials, produce defective nanomaterials, etc. problems, to reduce errors, save labor, and avoid solution contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is described in detail below in conjunction with accompanying drawing:

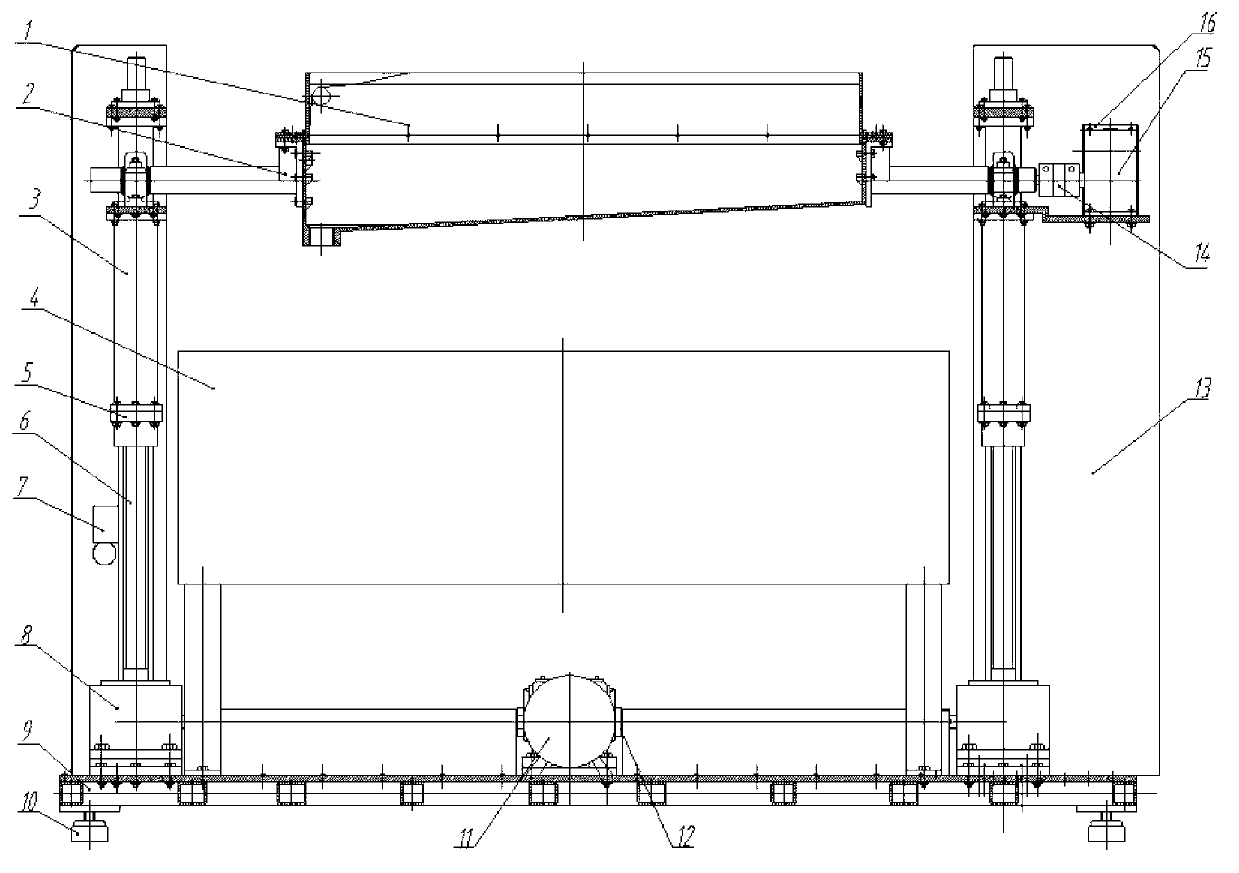

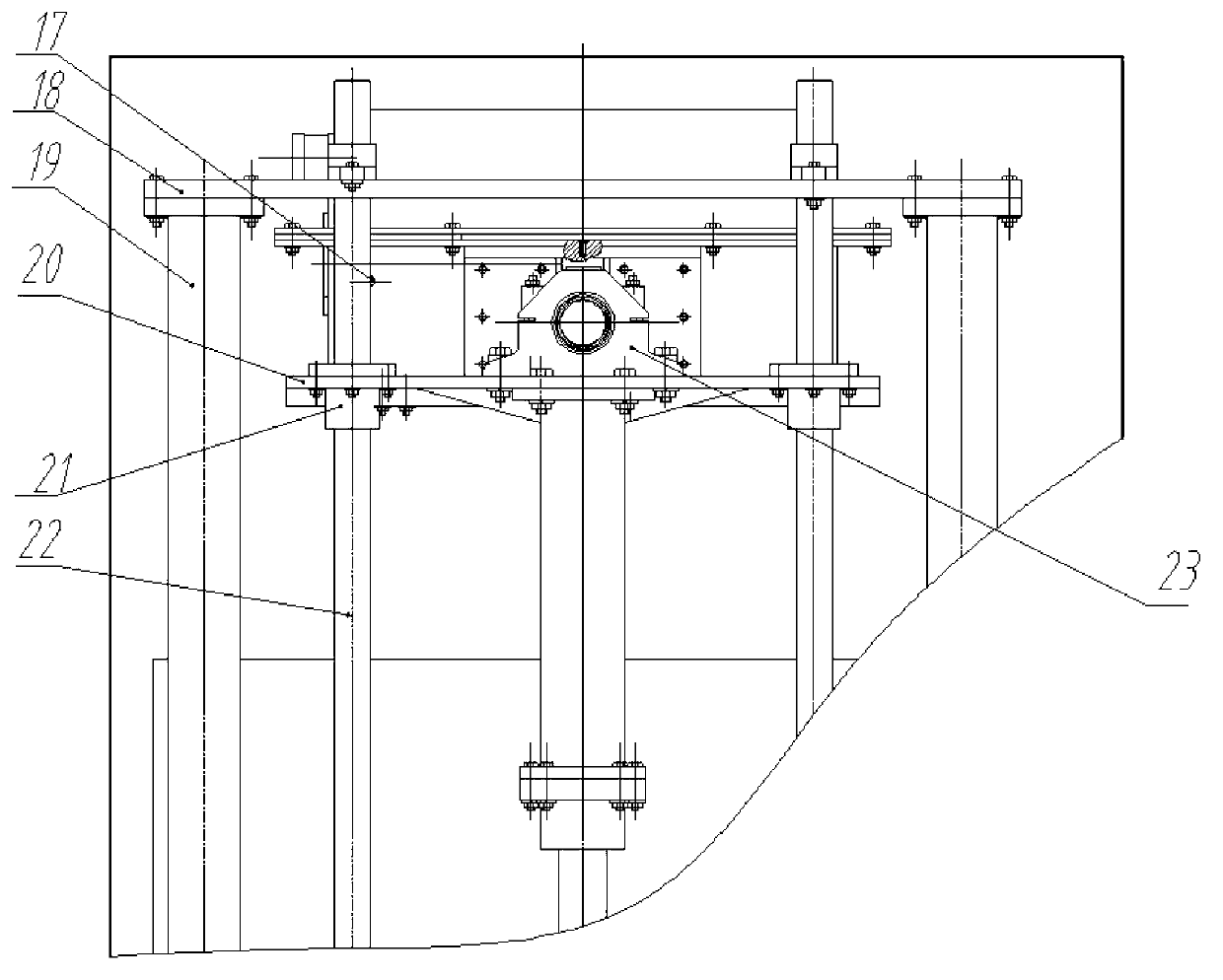

[0055] like figure 1 As shown, a nanometer material automatic filter includes a funnel 1, the two sides of the funnel 1 are connected to a symmetrical lifting device through the funnel support shaft 2, an ultrasonic cleaning machine 4 is arranged below the funnel 1, and the bottom of the funnel 1 is connected to a vacuum pump 34 connected;

[0056] The nanomaterial automatic filter also includes a cleaning liquid pump 42, the cleaning liquid pump 42 is connected to the cleaning liquid bucket 41 through a hose, and the cleaning liquid bucket 41 is connected to the nozzle device;

[0057] The ultrasonic cleaning machine 4, the cleaning liquid pump 42 and the vacuum pump 34 are connected with the control host through the control circuit board.

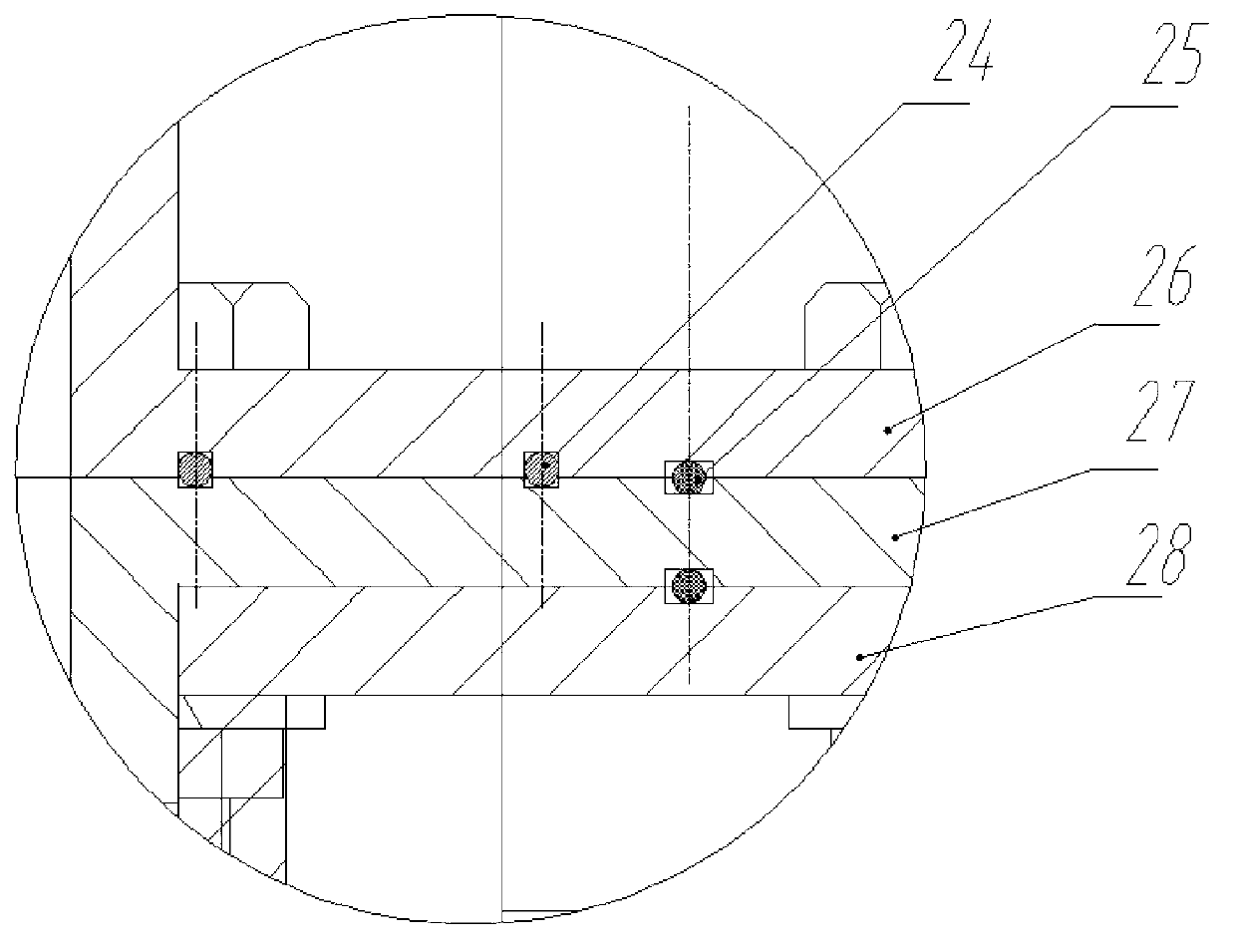

[0058] Funnel 1 comprises funnel top board 26, funnel middle board 27 and funnel base 28, and funnel top board 26 bottoms have two ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com