A wind separator for multi-stage separation of tobacco stems and tobacco flakes

A multi-stage separation and air separator technology, which is applied in solid separation, separation of solids from solids by air flow, and tobacco, etc., can solve the problems of reducing the use value of materials, reducing the size of materials, and intense mechanical friction. Simple structure, high utilization rate and high wind separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

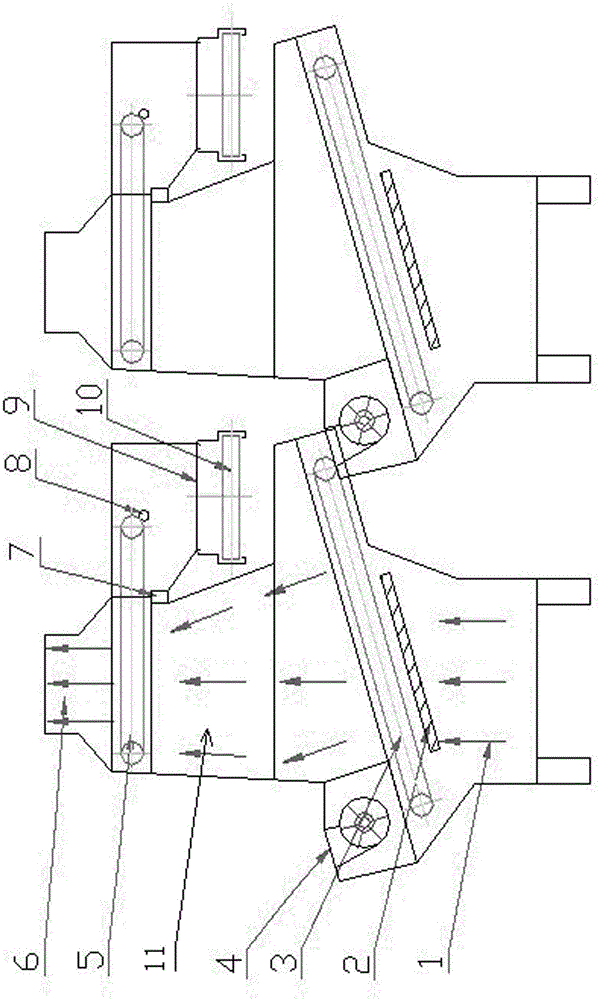

[0024] In the present invention, through the conveying mesh belt (3) installed inside the last independently working air separator, the materials that do not meet the requirements are directly transported from the outlet of the last independently working air separator to the next independently working air separator In the feed inlet, let the material that does not meet the requirements be air-separated again in the next independently working air separator. In this way, through several wind separators connected in series, direct, multiple, graded and fine air separation can be carried out continuously on the tobacco stem and tobacco sheet materials.

[0025] In the present invention, due to the different wind pressure and wind speed in each air separator, the specifications and sizes of the independent working separation chambers are different, the material flow rate is different, and the conveying mesh belt and conveying mesh belt speed are different, so as to realize the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com