Separator for separating solid particles from a vapour-gas mixture

A gas mixture and solid particle technology, applied in the field of separators, can solve the problems of reducing the separation efficiency of the device, and achieve the effect of avoiding penetration and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

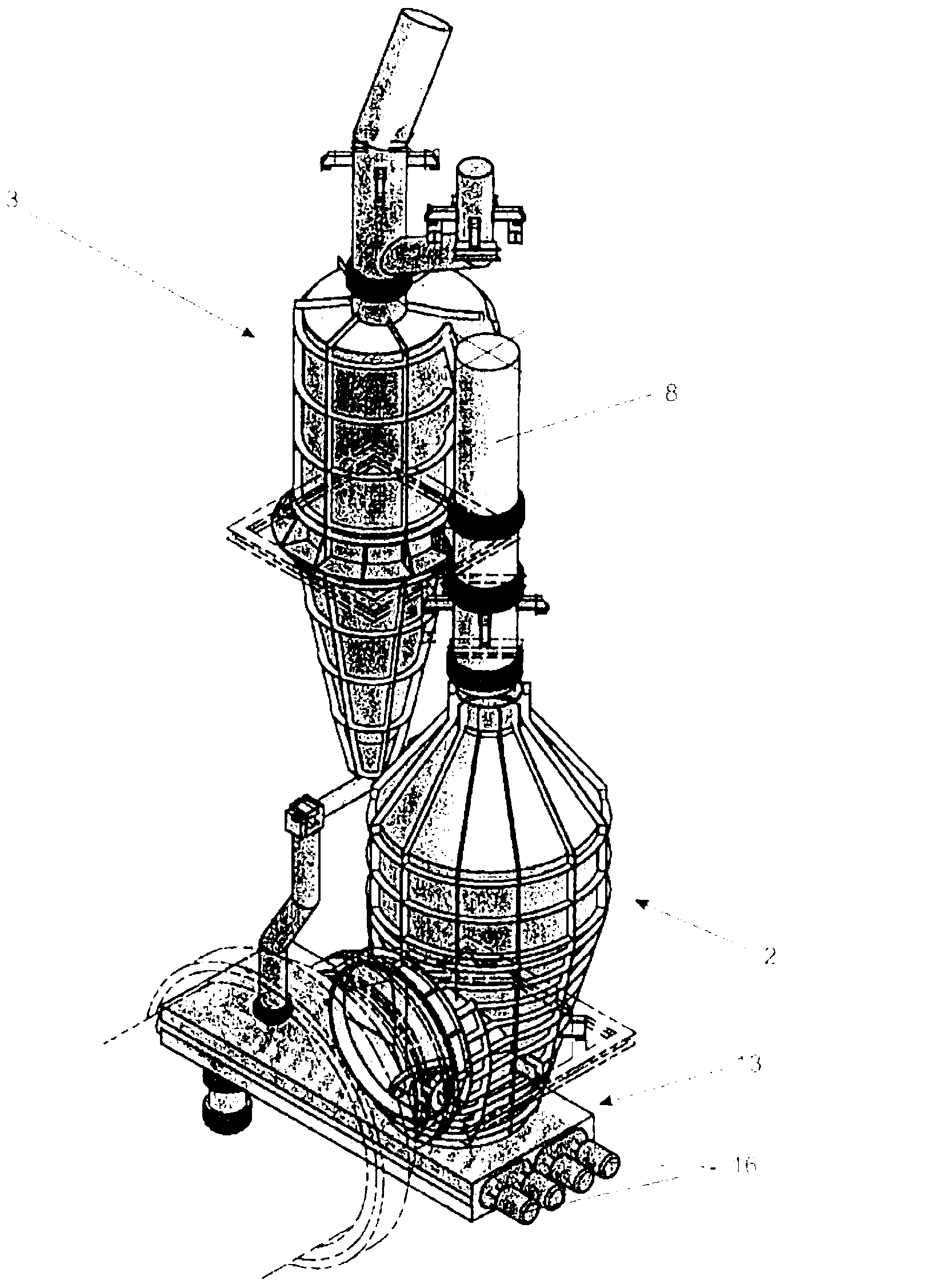

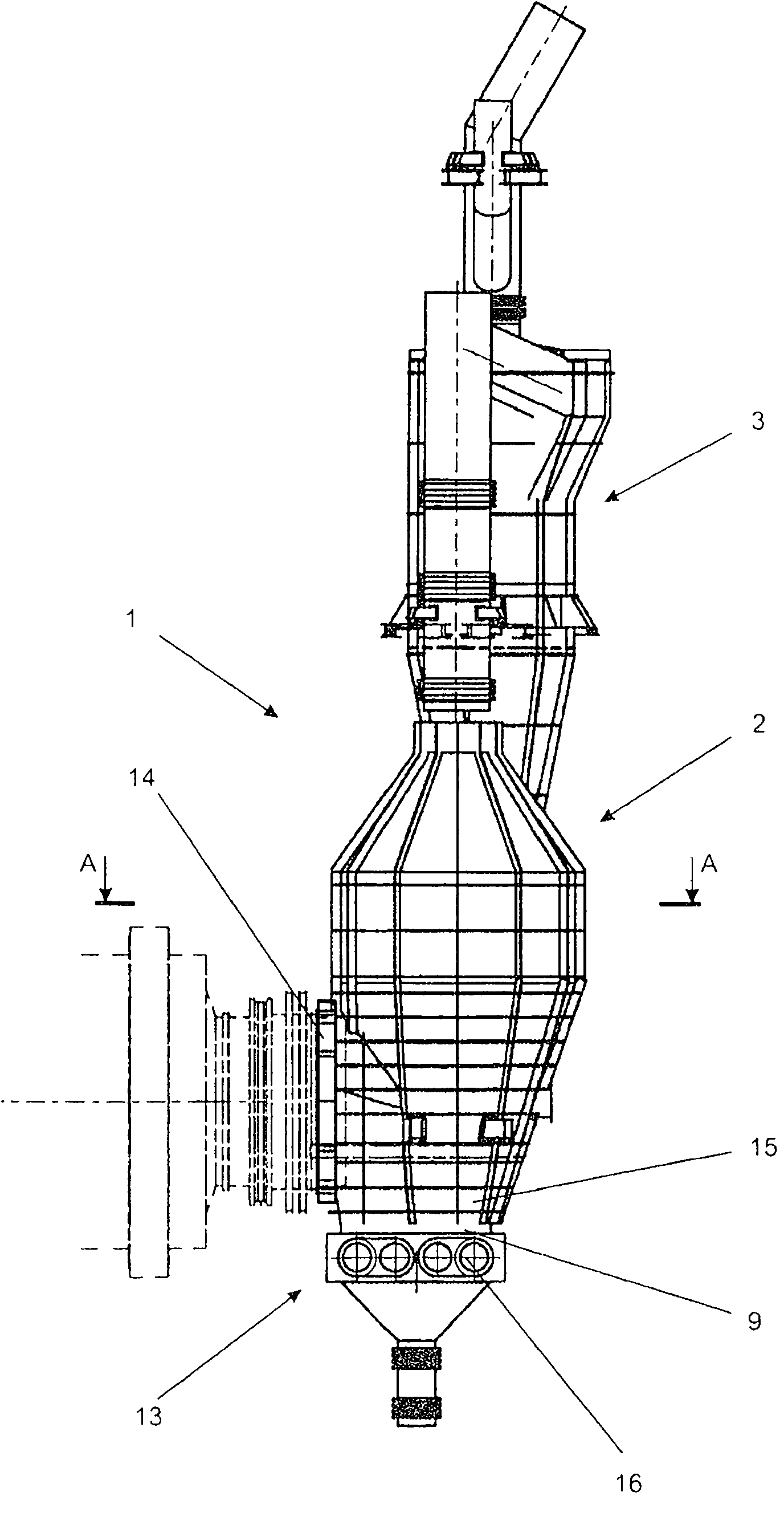

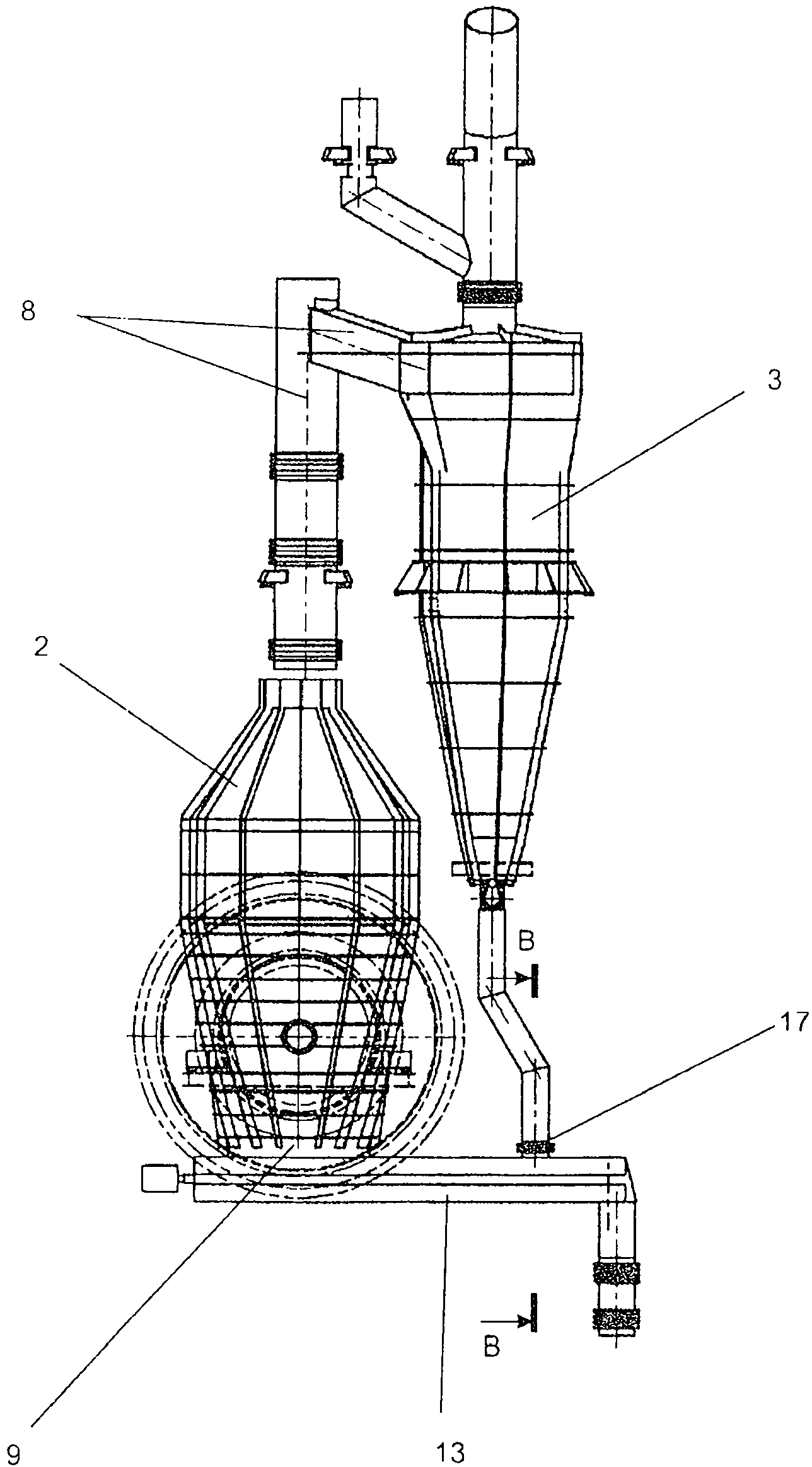

[0036] Pyrolysis of pulverized fossil fuels (e.g. oil shale) or materials containing organic matter occurs in a retort using a solid heat carrier process and thereafter, up to 1200 g / Nm 3 The steam-gas mixture (at standard pressure and temperature) containing semi-coked particles, hydrocarbon vapors, water vapour, cracked gas and other gases is directed to a separator 1 comprising a dedusting chamber 2 for separating from the steam The gas mixture separates solid particles. The temperature of the steam gas mixture entering the processing unit is about 460°C to 520°C.

[0037] The solids contained in the steam-gas mixture are separated in this device by the gravitational settling of the particles in the dedusting chamber 2 and by the centrifugal force in the cyclone 3 .

[0038] figure 1 A separator 1 according to the invention for separating solid particles from a vapor-gas mixture, shown in , comprises a dedusting chamber 2 having a main body 4 (see Figure 4 ), the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com