Optical performance detection device of liquid crystal projector

A detection device and optical performance technology, which is applied in the direction of testing optical performance, etc., can solve the problems of many workers, missed inspections and misjudgments, and low inspection efficiency, so as to avoid missed inspections, realize automatic storage, and reduce inspection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

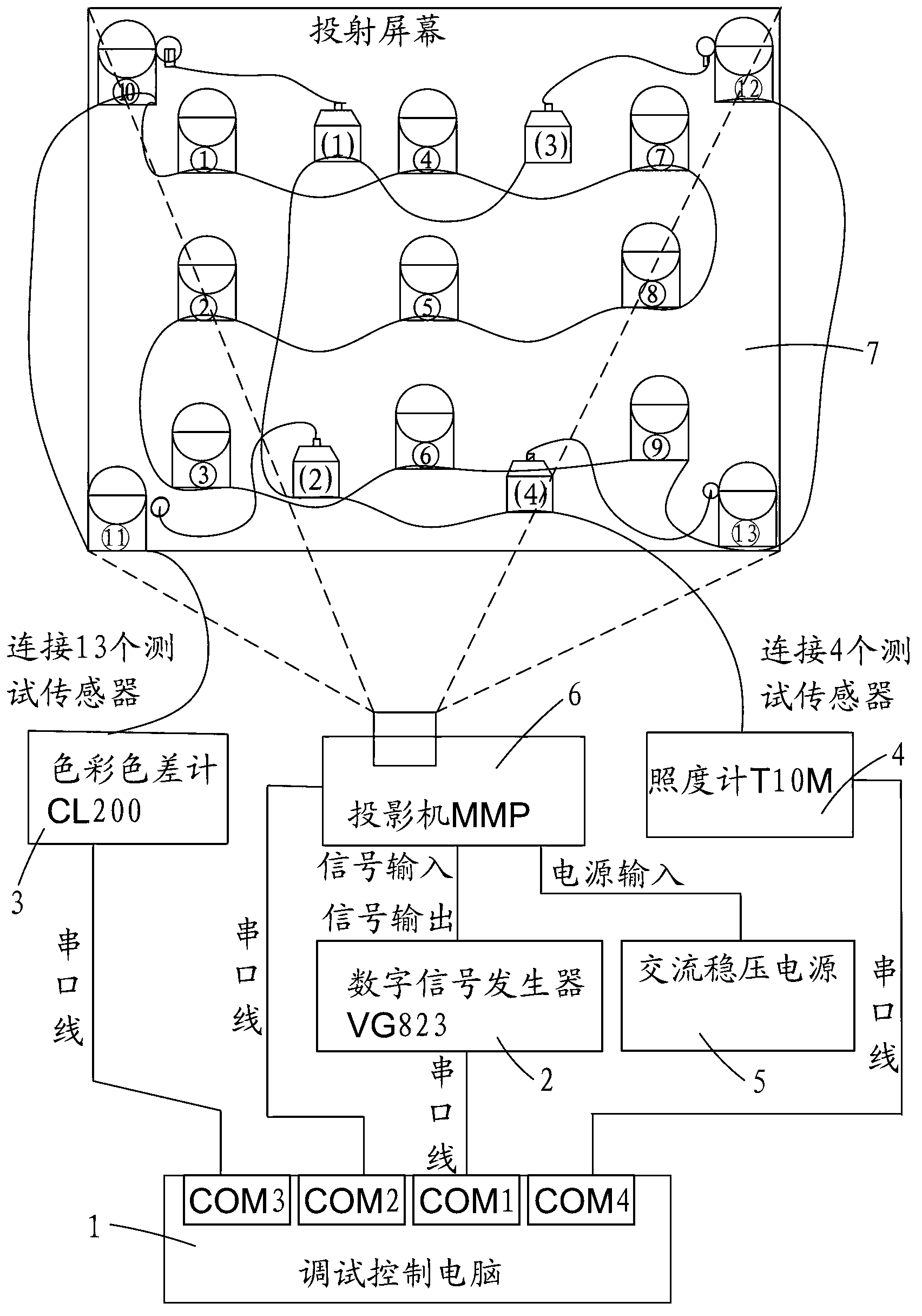

[0016] see figure 1 As shown, the embodiments of the present invention will be described in detail. The optical performance testing device in the production process of liquid crystal projectors, which includes: a debugging control computer 1, a digital signal generator VG8232, a color difference meter CL2003, a brightness meter T10M4, an AC stabilized voltage power supply 5, and a projector to be tested 6.

[0017] The debugging control computer 1 has four control ports COM1, COM2, COM3, and COM4, wherein the control port COM1 is connected to the digital signal generator VG823 2 through a serial communication line, and the control port COM2 is connected to the projector 6 to be tested through a serial communication line ; The control port COM3 is connected to the color difference meter CL200 3 through a serial communication line; the control port COM4 is connected to the luminance meter T10M 4 through a serial communication line.

[0018] The projector 6 to be detected is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com