Lever type steel coil on-line weighing metering device

A measuring device and lever-type technology, which is applied in the field of lever-type steel coil online weighing and measuring device, can solve the problems of high center of gravity, difficult limit and unsafe operation of the weighing system, and achieve reduced failure rate and good stability , Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

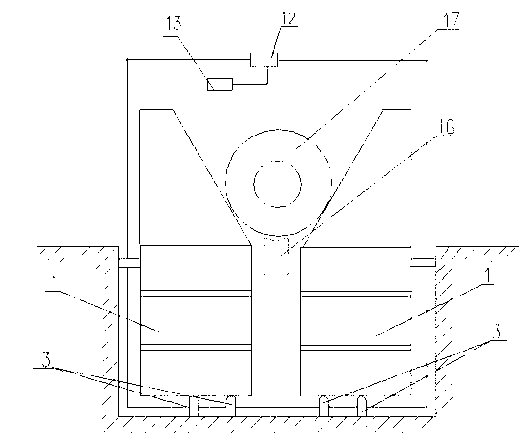

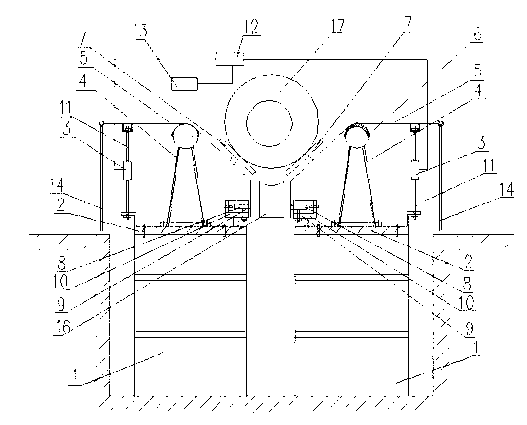

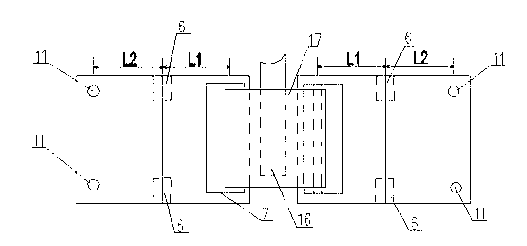

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

[0022] like figure 2 , image 3 As shown, a lever-type steel coil online weighing and measuring device is used to fix the weighing platform base 2 with bolts or direct welding on a set of (two) frames 1 on both sides of the guide groove of the walking beam 16 in the production line. Two sets of (two) support frames 4 are arranged longitudinally parallel to the middle position of the weighing platform base 2, and are fixed on the weighing platform base 2 with bolts; A set of inclined weighing table 5 constitutes a "V"-shaped weighing table mechanism in section. In order to strengthen the strength of the inclined weighing table 5, 2 vertical, 2 horizontal and 4 reinforcing ribs are added on the back of the inclined weighing table 5 (in the figure not shown), so that the inclined weighing table 5 will not be deformed. A set of (two) bushings 6 are welded and fixed long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com