Method for improving the content of characteristic aroma component ethyl propionate of special-flavor Chinese spirits

A characteristic technology of ethyl propionate, which is applied in the field of increasing the content of ethyl propionate, a characteristic aroma component of special-flavor liquor, can solve the problems that the content of ethyl propionate needs to be increased, and achieves the reduction of cultivation cost and acid resistance. Good, quality-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

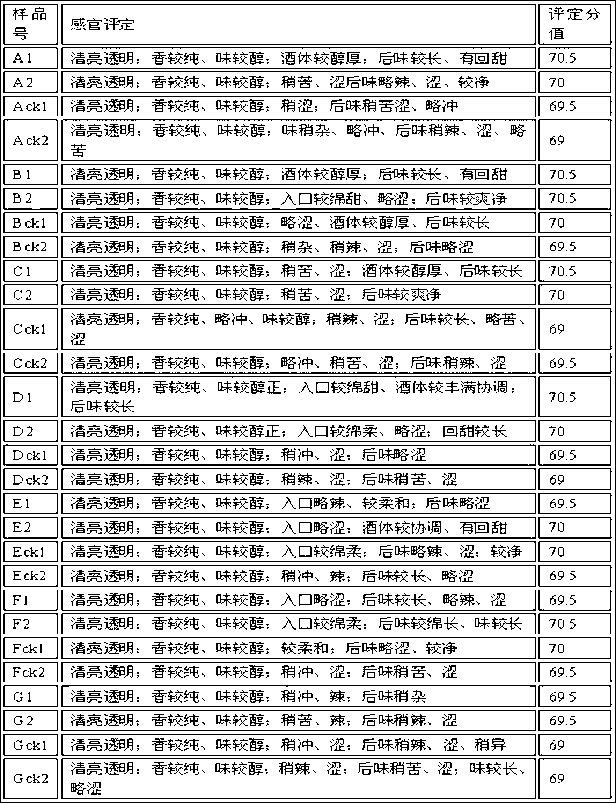

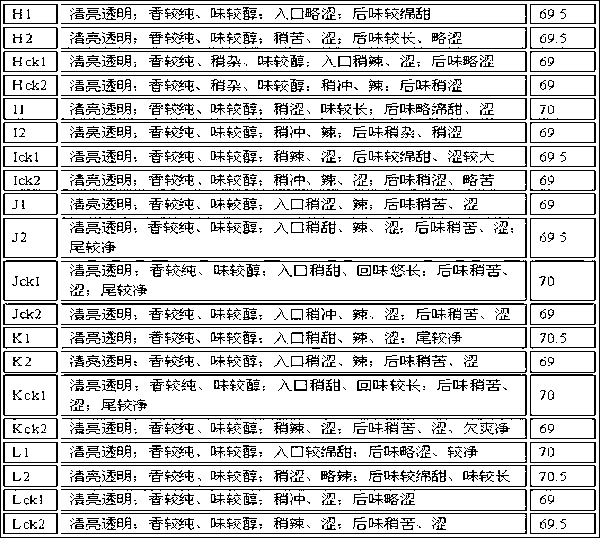

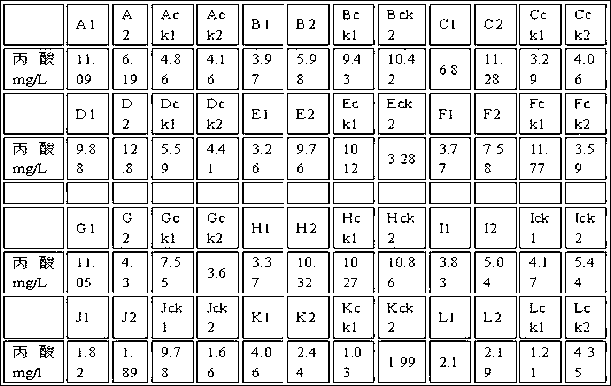

[0009] Select 48 cellars in the brewing workshop of a limited liability company, and divide them into 12 batches of experiments. Each time, 2 experimental cellars are selected and filled with the same amount of propionic acid bacteria solution, and the other 2 are blank control cellars. The volumes of the first to fifth batches are 25kg, 20kg, 15kg, 10kg, and 5kg, and the volumes of the sixth to twelfth batches are 5kg, 10kg, 15kg, 20kg, 25kg, 25kg, and 25kg. Drill 5 holes evenly on the cellar, divide the propionic acid bacteria solution into 5 parts, and pour them into 5 holes respectively. The diameter of each hole is 3.5 cm and the depth is 30 cm. Cellar filling time: the 15th day after the fermented grains are put into the pond for fermentation.

[0010] A represents the first batch of experiments (A1 represents the first experimental cellar, Ack1 represents the blank cellar of the first experiment, A2 represents the second experimental cellar, Ack2 represents the blank ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com