Manufacturing method of modified meerschaum

A manufacturing method and a sepiolite technology are applied in the field of environmental engineering and can solve the problems of small channels, weak surface acidity of natural sepiolite, weak heavy metal adsorption capacity and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

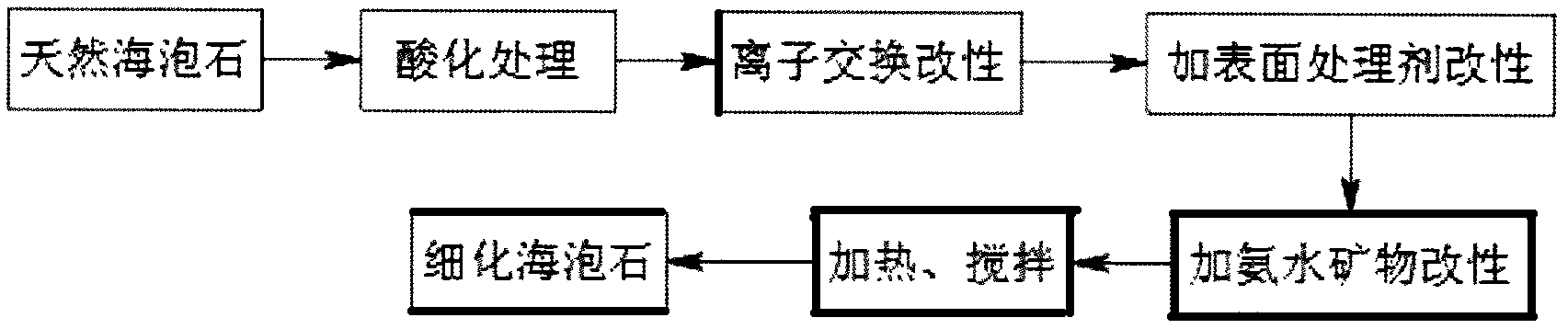

[0019] see figure 1 , a kind of manufacture method of modified sepiolite, comprises the steps:

[0020] Acidification treatment: Although different strong acids have the same treatment mechanism for sepiolite, compared with the treatment results of nitric acid, sulfuric acid and hydrochloric acid, hydrochloric acid has the best effect, and the adsorption capacity of sepiolite is related to the concentration of hydrochloric acid used for acid activation. Great relationship, too large or too small acid concentration will affect the properties of sepiolite, use 15%-17% hydrochloric acid to acidify sepiolite at a temperature of 453K-473K, the results show that the treated sepiolite The pore structure changes, the diameter of the original micropores expands, and the surface area increases significantly. Generally, the more micropores in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com