Omni-directional moving unit module structure of modularized self-reconfiguration robot

A unit module and modular technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of less docking surfaces, complex structures, and insufficient movement capabilities, and achieve convenient reconfiguration, space saving, and enhanced mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

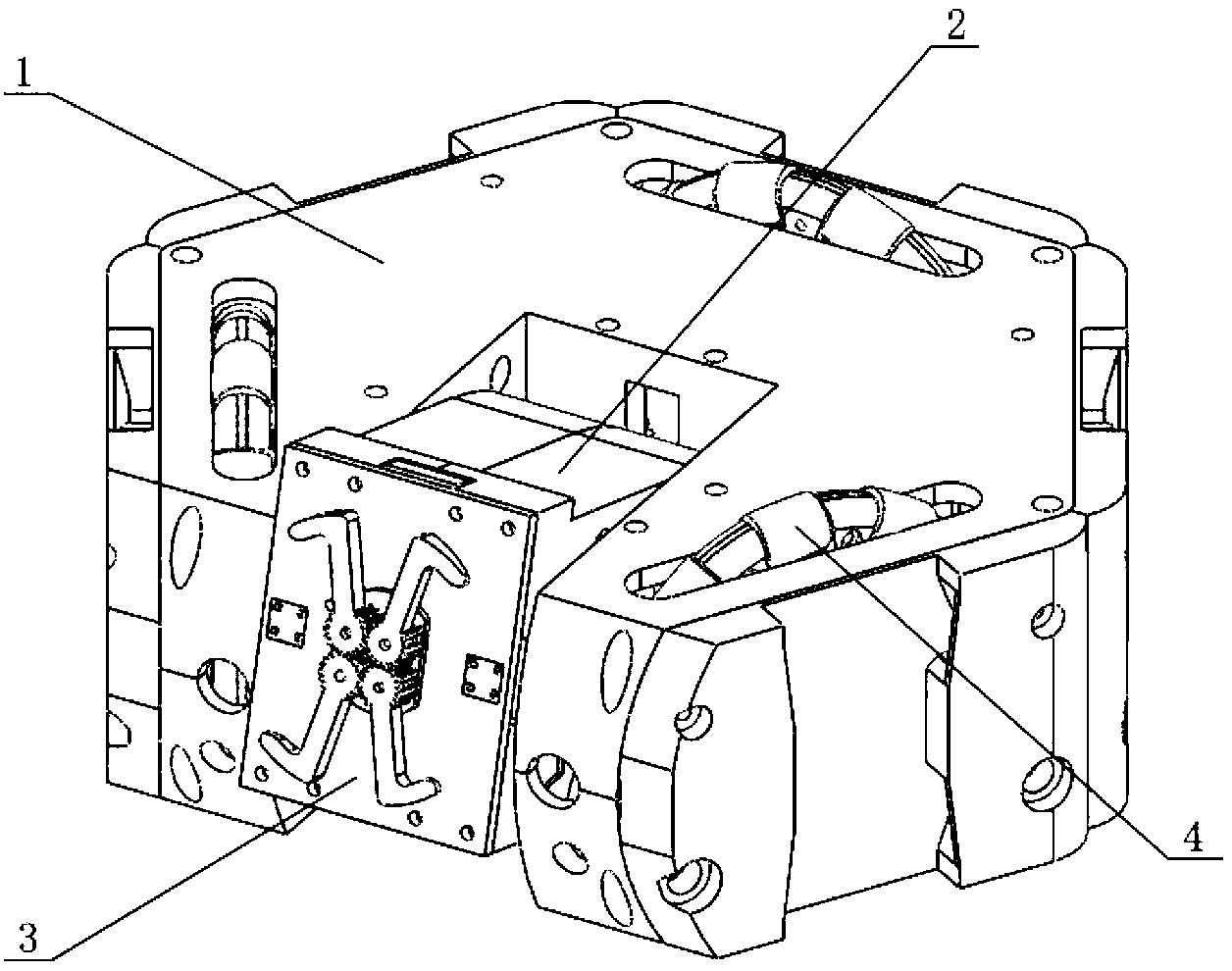

[0036] figure 1 It is the overall structure diagram of the unit module according to the present invention. As shown in the figure, the unit module of the present invention is composed of a unit module body 1 , a unit module pitch joint 2 , a unit module docking device 3 and a unit module moving wheel device 4 . The pitch joint, docking device, and moving wheel device are installed and fixed on the unit module body, wherein the pitch joint of the unit module can rotate 90° up and down around the axis.

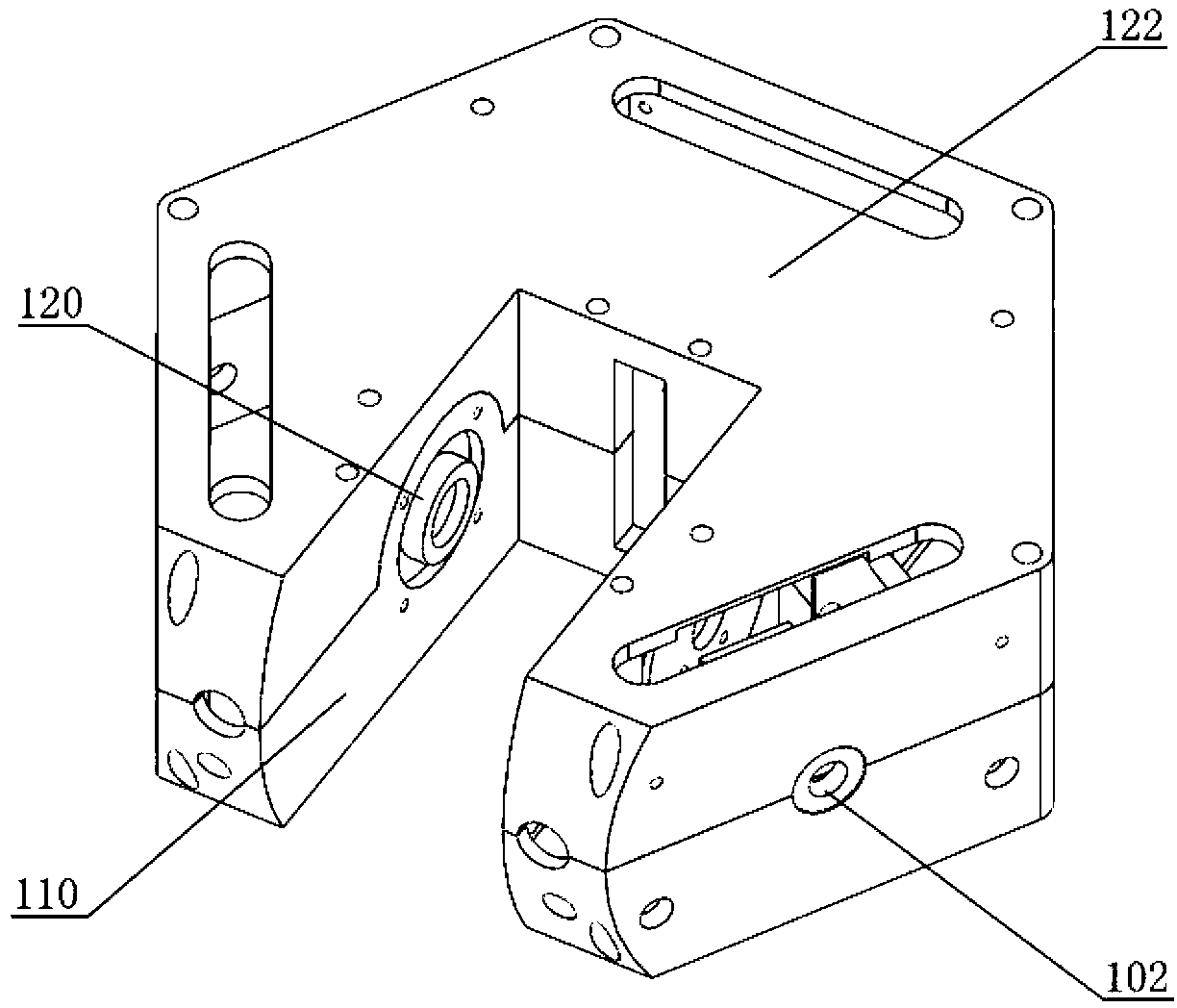

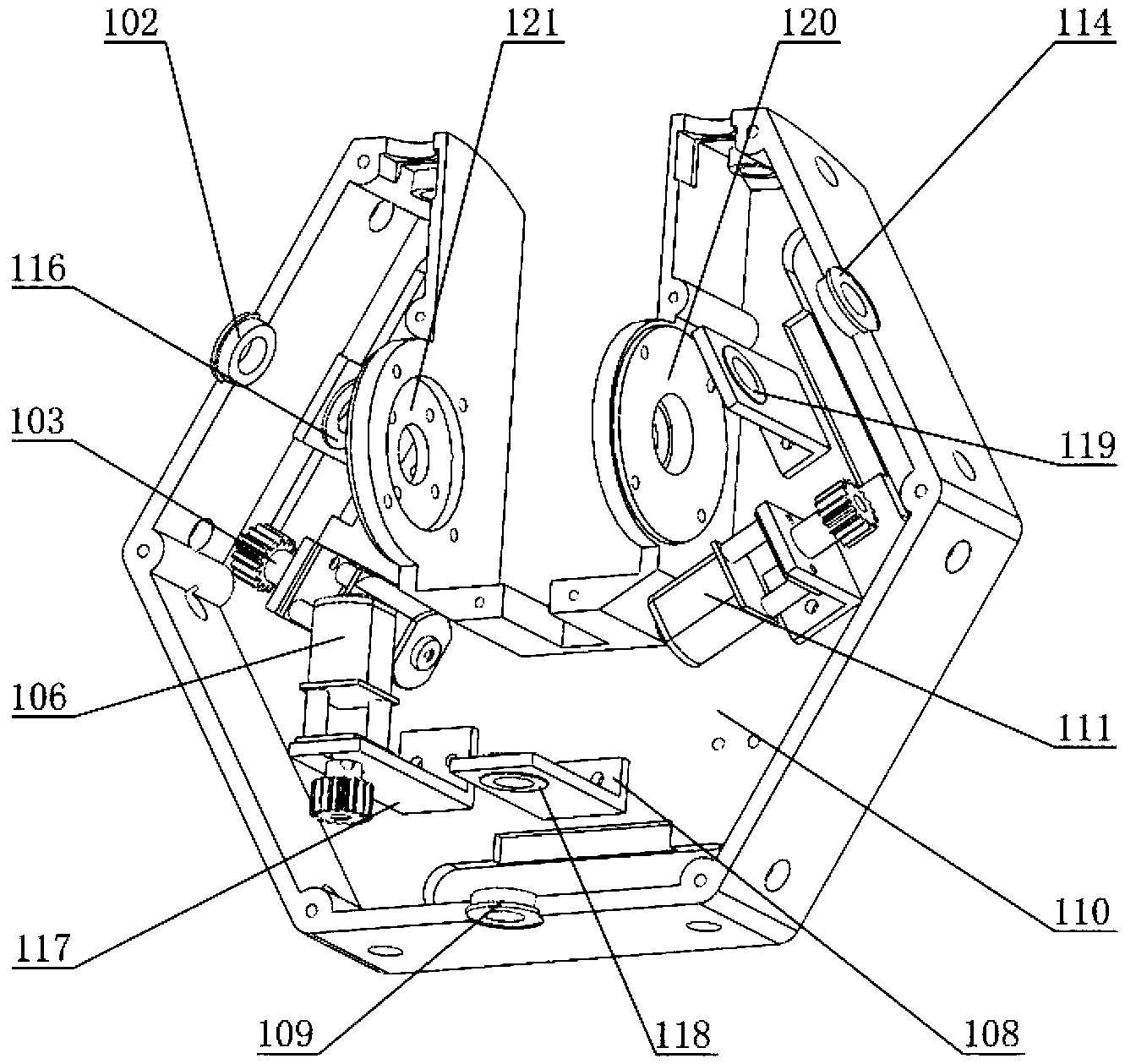

[0037] figure 2 It is the overall structure diagram of the unit module fuselage. Such as figure 2 As shown in the figure, the overall fuselage is in the shape of a hexahedron, which is mainly formed by connecting and fixing the upper half of the fuselage and the lower half of the fuselage. For the structure of the upper and lower parts of the fuselage, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com