Trimming and burr clearing device for orifice

A technology of burr cleaner and burr, which is applied in the field of orifice burr and burr cleaner, can solve the problems of low efficiency, cluttered high-precision installation plane, cumbersome and other problems, and achieves easy and labor-saving use, easy to purchase, and portable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

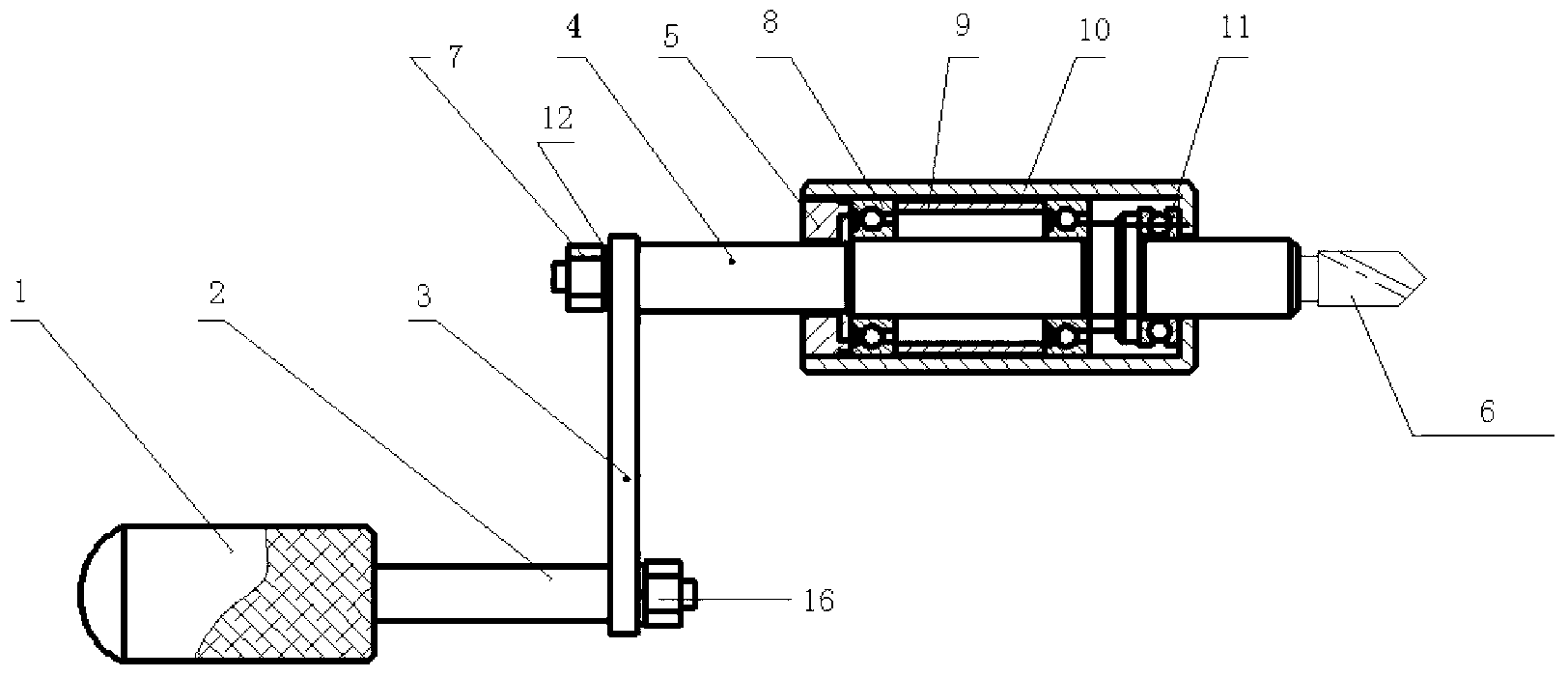

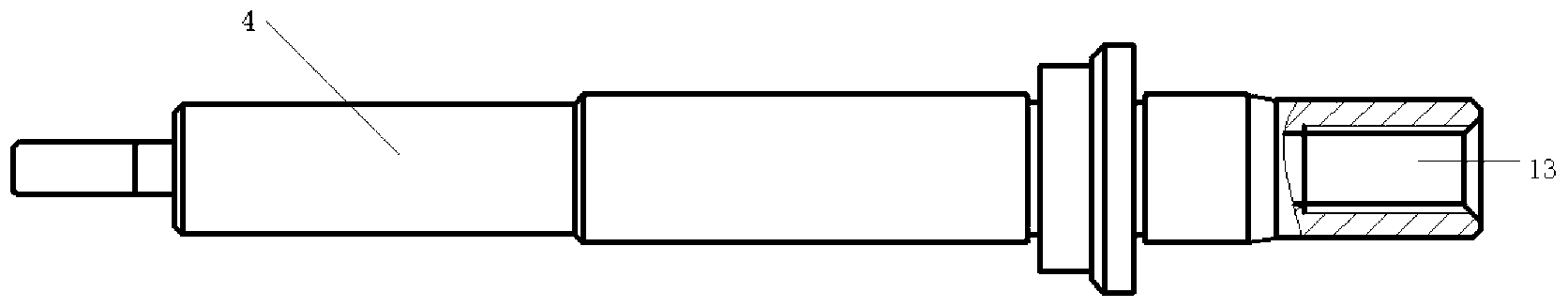

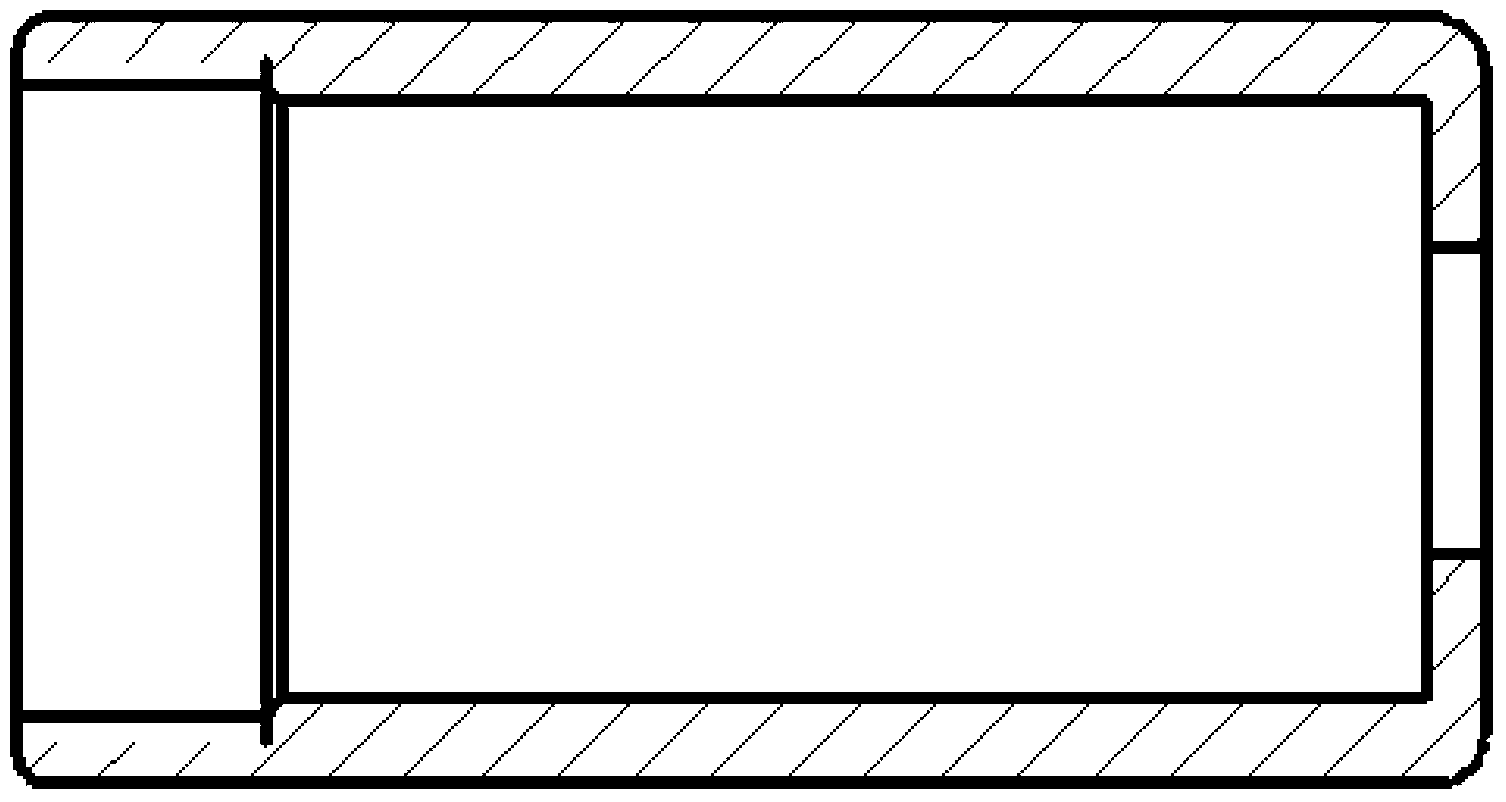

[0030] refer to Figure 1 to Figure 7 , orifice flash and burr cleaner, including handle 1, rocker arm 2, connecting rod 3, main shaft 4, chamfering countersink 6 and housing 10, the housing 10 is a hollow structure and its interior is provided with the A main shaft 4, one end of the main shaft 4 protrudes from the housing 10 and is in transmission connection with the connecting rod 3, and the other end protrudes from the housing 10 and is detachably connected with the chamfering countersink 6; One end of the connecting rod 3 is provided with a first through hole 14, the main shaft 4 passes through the first through hole 14 and is connected with the connecting rod 3 through the first nut 7, and the connecting rod 3 can drive the main shaft 4 rotation; the other end of the connecting rod 3 is provided with a second through hole 15, and one end of the rocker arm 2 passes through the second through hole 15 and is fixedly connected to the connecting rod 3 through a second nut 16; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com