Battery cell, battery cell module, method for producing a battery cell module and motor vehicle

A battery cell and motor vehicle technology, applied in battery/battery traction, secondary battery manufacturing, large flat battery/battery, etc., can solve problems such as unsuitable assembly costs, and achieve low power loss and good overall efficiency operation , The effect of reducing the contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

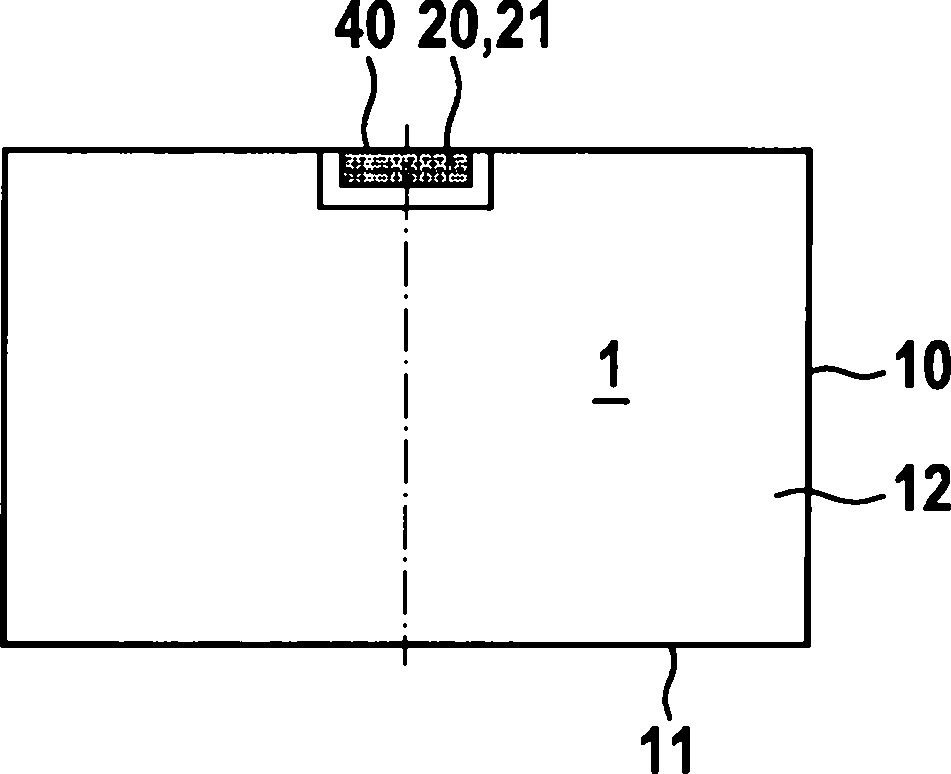

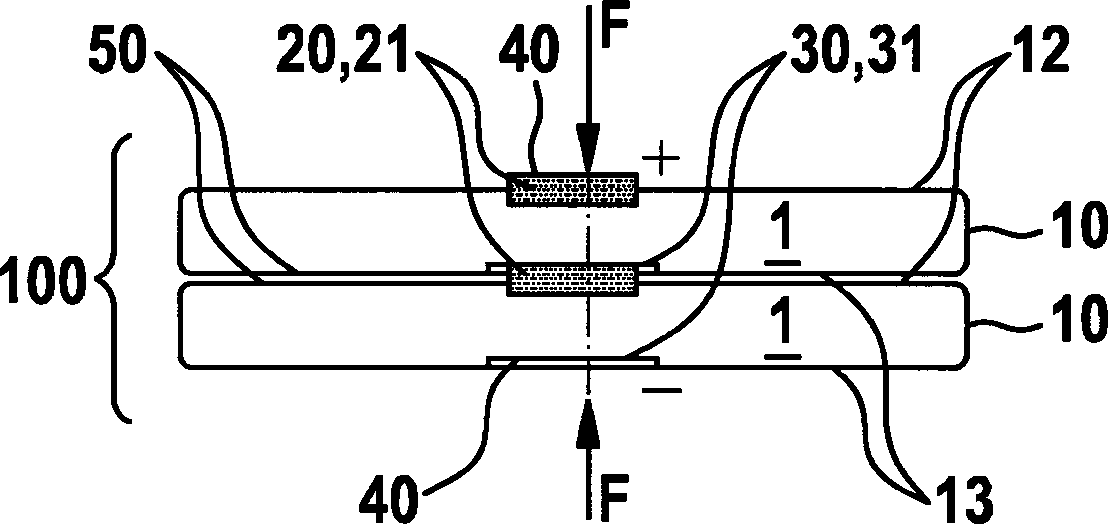

[0032] exist figure 1 A battery cell 1 is shown in , which has a substantially rectangular cell housing 10 . The cell housing 10 comprises a base surface 11 arranged on the bottom side, as can be obtained in particular from figure 2 As can be seen in , the first side 12 and the second side 13 , which are arranged parallel to each other, extend substantially perpendicularly from the base surface 11 .

[0033] exist figure 1 The first side 12 can be seen in the figure 1 The views shown in the corresponding figure 2 The view of the battery cell module 100 shown in , drawn from top to bottom, in the direction of the pressing force F acting on the positive pole.

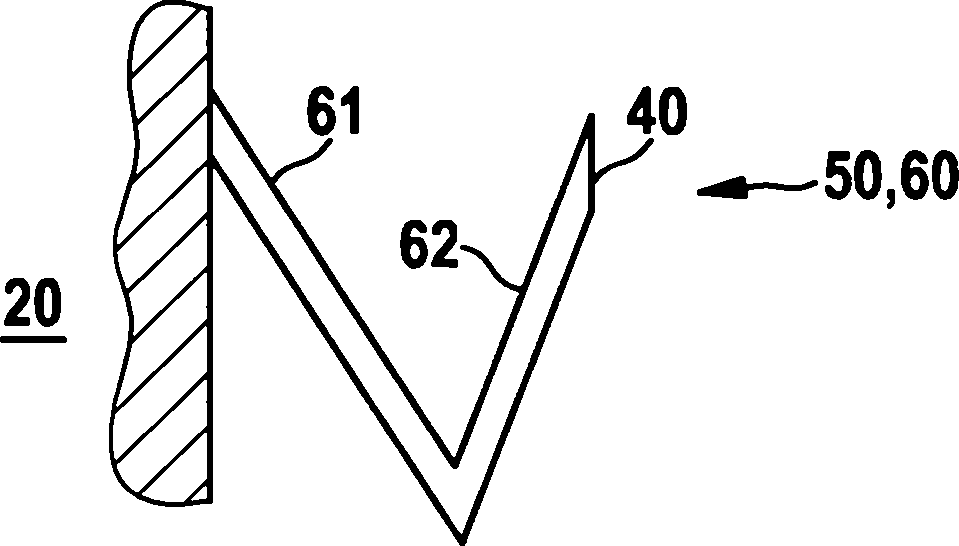

[0034] exist figure 1 A first terminal 20 is arranged on the first side 12 shown in . The first terminal 20 has a contact surface 40 . exist figure 1 In the embodiment shown in , the first terminal 20 comprises a block 21 .

[0035] That is to say, unlike conventional battery cells, on the battery cell 1 accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com