A kind of wind power generation device

A wind power generation device and wind power technology, which is applied to electromechanical devices, wind turbines, and wind turbines at right angles to the wind direction, etc., can solve the problems of poor typhoon resistance performance of wind power generation devices, many wind power generation device components, and low generator efficiency. , to achieve the effect of improving anti-typhoon performance, good heat dissipation effect and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

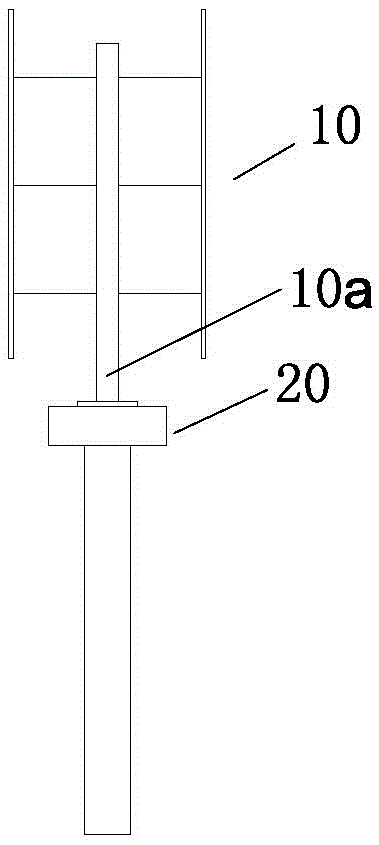

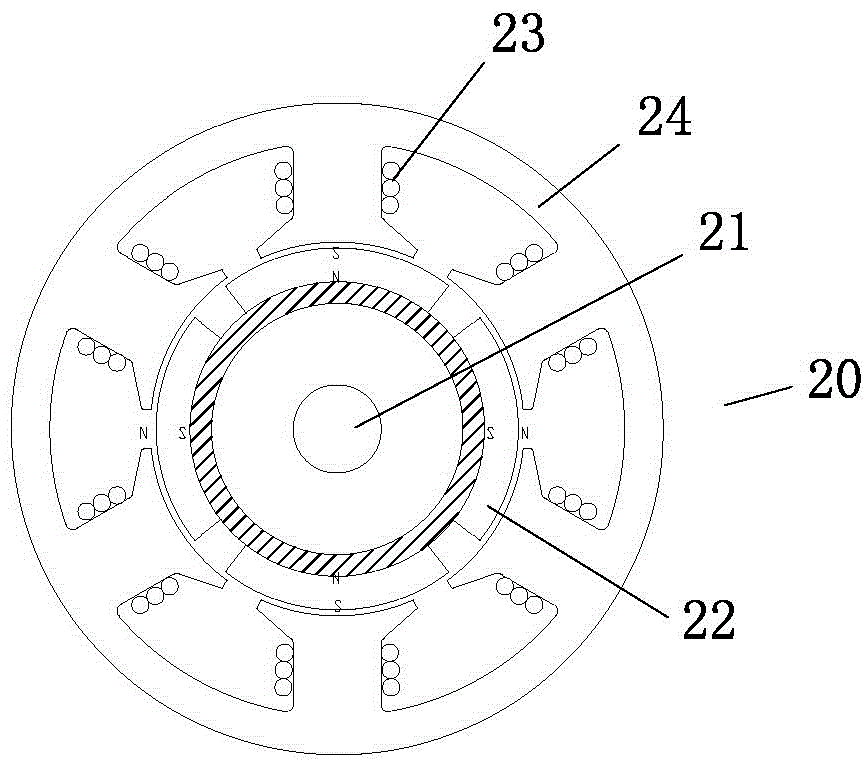

[0029] Such as Figure 1-2 Shown is the cylindrical wind power generation device in the prior art and the cross-sectional view of the existing generator, which can be obtained from figure 1 It can be seen that the existing wind power generation device is formed by connecting two parts of the fan blade drum 10 and the generator 20, and the central rotating shaft 10a of the fan blade drum 10 is connected with the input shaft of the generator 20 to drive the generator to work and generate electricity; figure 2 It can be seen that the structure of the existing generator 20 is composed of a central shaft 21 , a rotor formed by several magnets 22 and several group winding coils 23 fixed on the outer ring. The winding coils 23 are wound on the core 24 . The drawbacks of this construction have been pointed out in the background art.

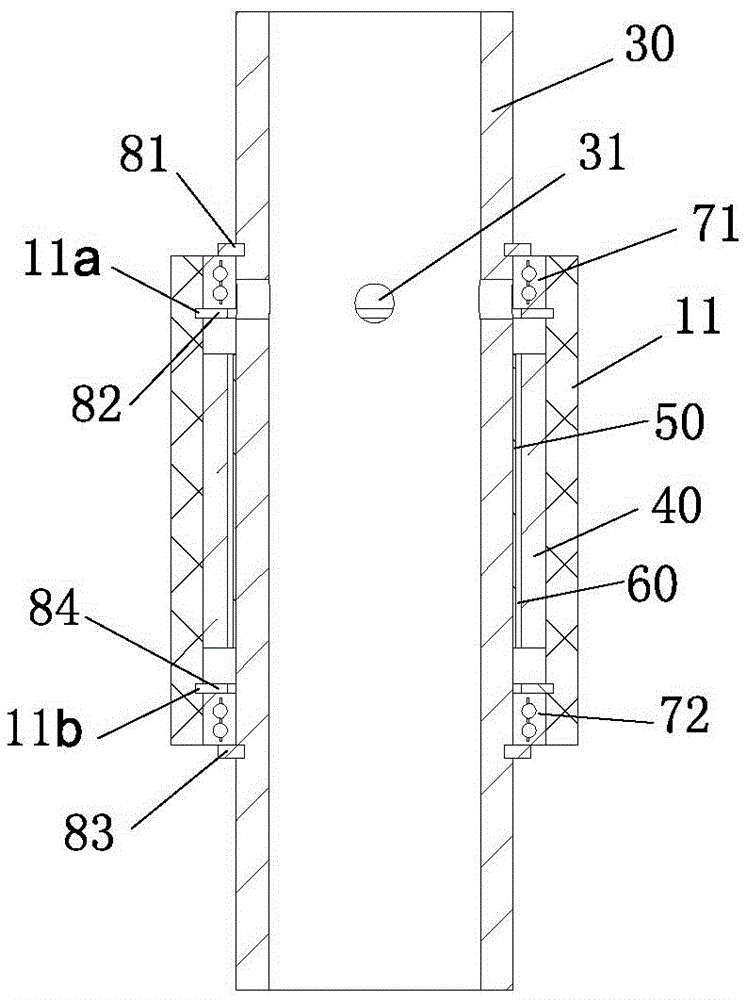

[0030] Figure 3-7 It is an embodiment of the present invention, and it includes: a fixed central shaft 30 and a blade rotor 10, the middle of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com