Compact direct coupling all-solid-state laser device

An all-solid-state, laser technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as poor stability of resonators, limited integration, and application limitations, and achieve laser stability, improved conversion efficiency, and energy. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

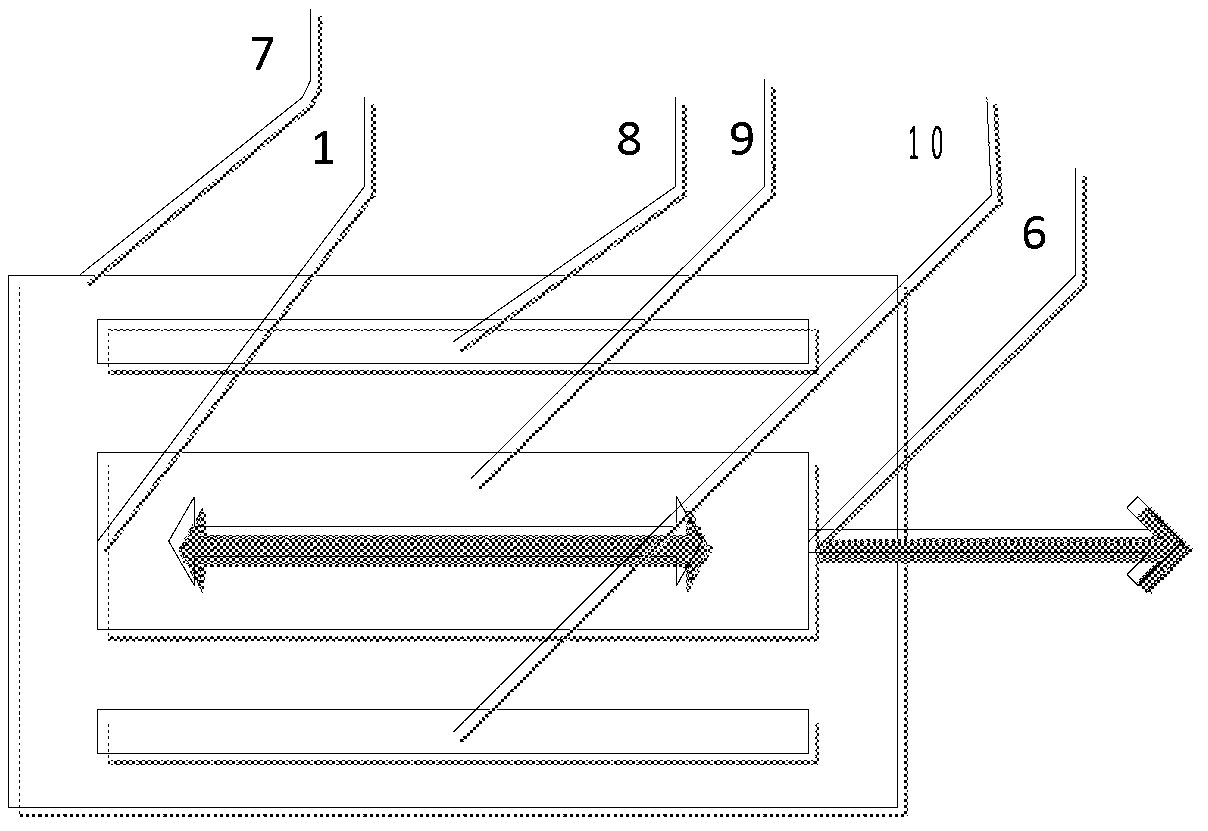

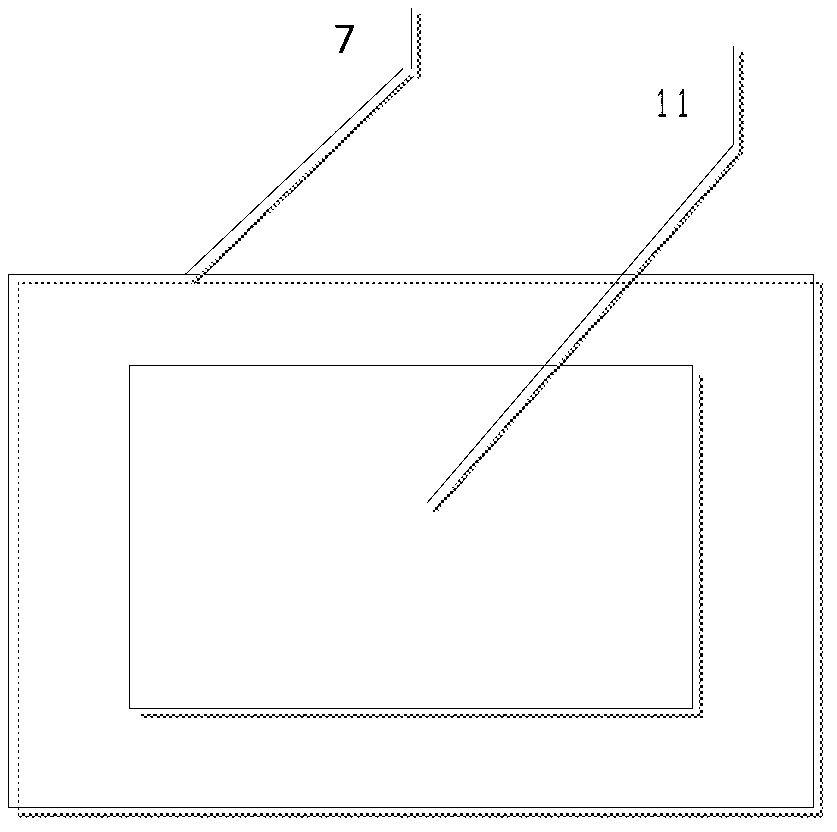

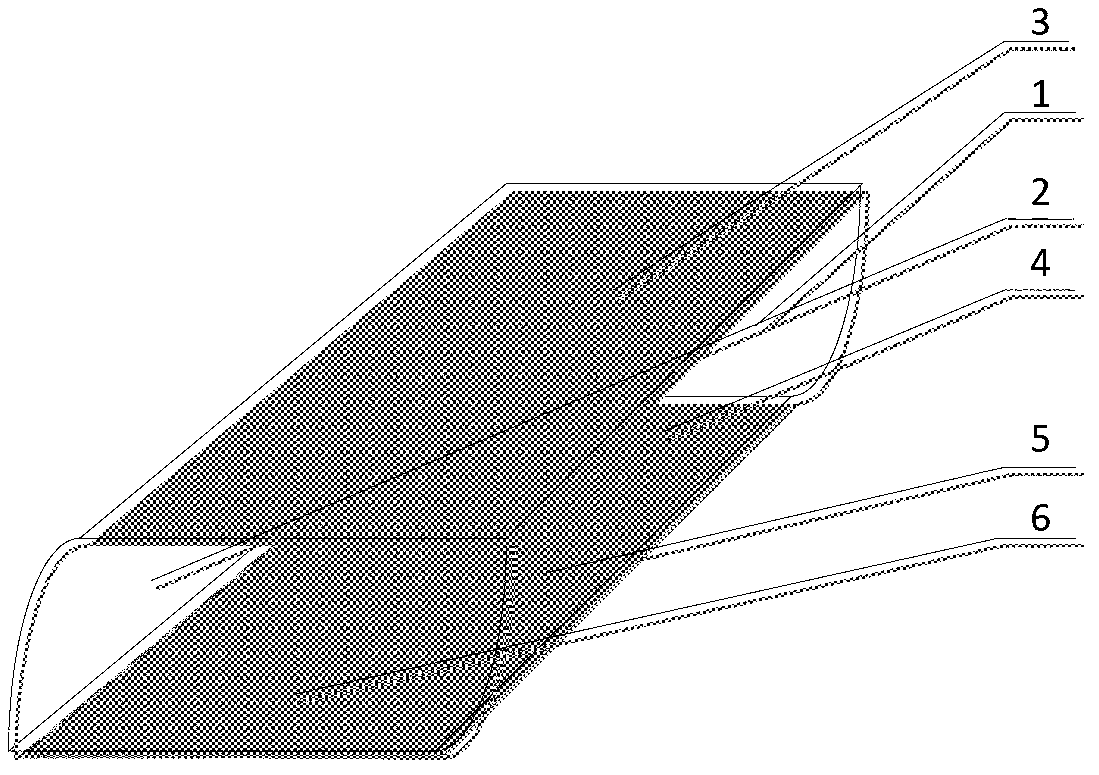

[0019] refer to Figure 1-Figure 3 , a compact direct-coupled all-solid-state laser, mainly including a laser diode pump source 8, a laser crystal 9 coated on the end face and side surface, a heat sink 7 and a semiconductor cooler 11, and the laser crystal 9 and the semiconductor cooler 11 are fixed on the heat sink respectively. On both sides of the Shen 7, the laser diode pumping source 8 is double-sided symmetrical pumping of the laser diode linear array, which are respectively located on both sides of the laser crystal 9. The two sides of the laser crystal 9 are designed with semi-cylindrical lenses for coupling the pump light. The two ends of the laser crystal are respectively coated with a film, which is used as a reflector of the laser resonator. The first laser crystal surface 1 is coated with a las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com