Jumper-connection-free optical fiber cross connecting cabinet

A fiber optic cable transfer box and jumper technology, which is applied in the field of optical communication, can solve problems affecting product quality, messy fiber distribution, inconvenient maintenance and management, etc., to facilitate line management and expansion, reduce construction and maintenance costs, and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

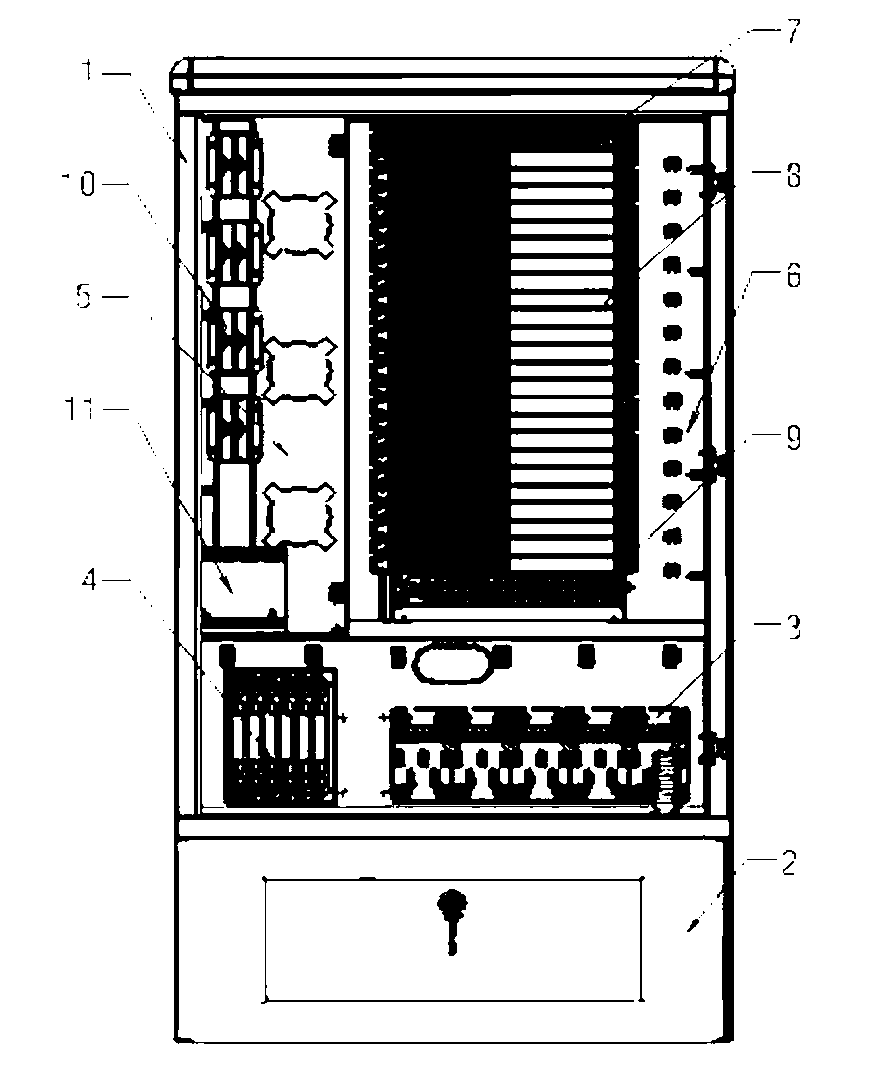

[0008] See figure 1 As shown, a jumper-free optical cable transfer box includes a box body 1, the box body 1 is installed on the base 2, and the box body 1 is provided with a trunk fusion and distribution integration unit 7, a wiring fusion storage integration unit 8, Direct melting unit 4, optical cable lead-in unit 3, a box-type optical splitter 10 is vertically arranged on the left side inside the box body 1, and a fiber storage unit is arranged between the box-type optical splitter 10 and the integrated wiring melting storage unit 8 The unit 5 and the redundant fiber jumper berth 11 are equipped with a fiber winding column 12 inside the fiber storage unit 5. The box-type optical splitter 10 has the characteristics of small size and good light distribution uniformity. The interior of the cabinet 1 does not need to take up too much space, and there is a large setting space for the fiber storage unit 5 and the redundant fiber jumper berth 11; the right side of the cabinet 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com