Protection material hot-cold pulse fatigue resistance test apparatus

A technology for protective materials and fatigue testing, applied in measuring devices, analyzing materials, using mechanical devices, etc., can solve problems such as unsatisfactory experimental equipment, and achieve fast cold and heat exchange time, high temperature control accuracy, and good temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

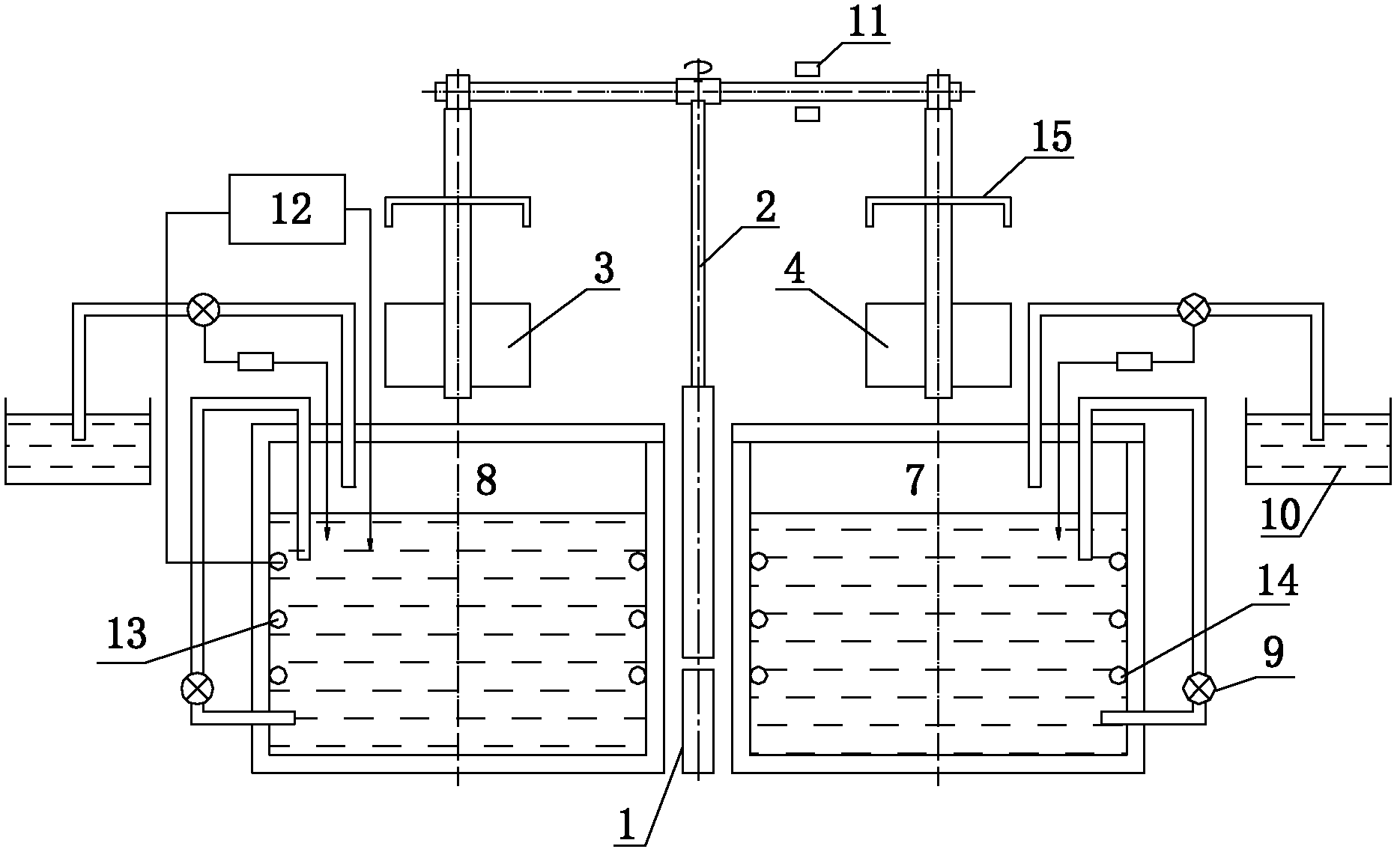

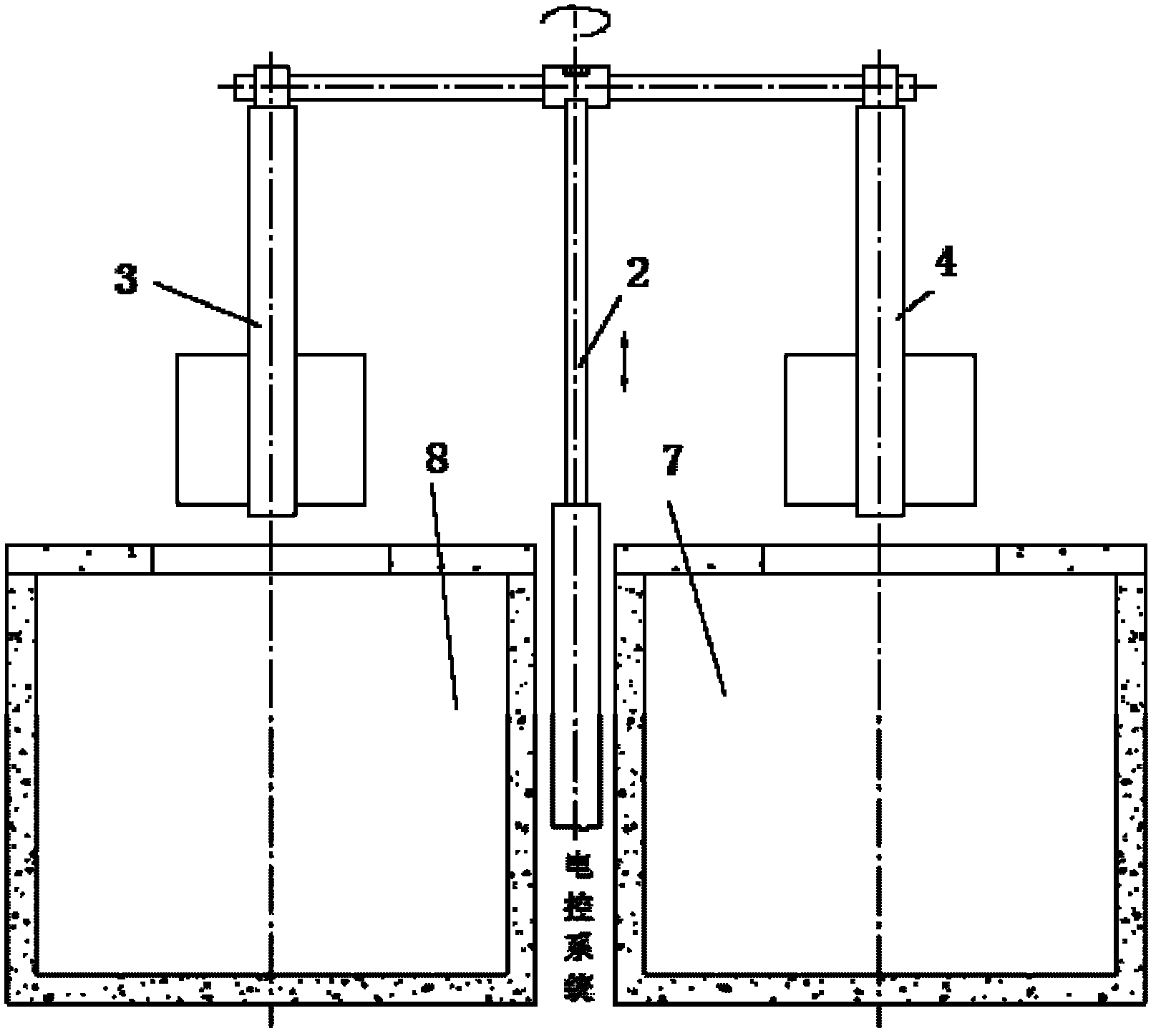

[0038] Such as figure 1 , 2 shows the coating anti-high frequency thermal pulse fatigue test device, which includes an electronic control system 1, a lifting and rotating device 2, two special sample racks: sample rack A3 and sample rack B4, two test tanks: high temperature Tank 7 and low temperature tank 8.

[0039] The sample rack A3 and the sample rack B4 are respectively vertically fixed on the left and right supports of the lifting and rotating device. The electronic control system 1 automatically controls the cylinder lifting and rotating device 2 to drive the sample holder A3 and the sample holder B4 of the two installed coating samples (6) to move up, down and counterclockwise high-frequency rotation. The low temperature tank 8 and the high temperature tank 7 are located vertically below the two sample racks.

[0040] Work process description:

[0041] Start the heating and condensing device before the experiment, then set the temperature of the high temperature tank to 95℃...

Embodiment 2

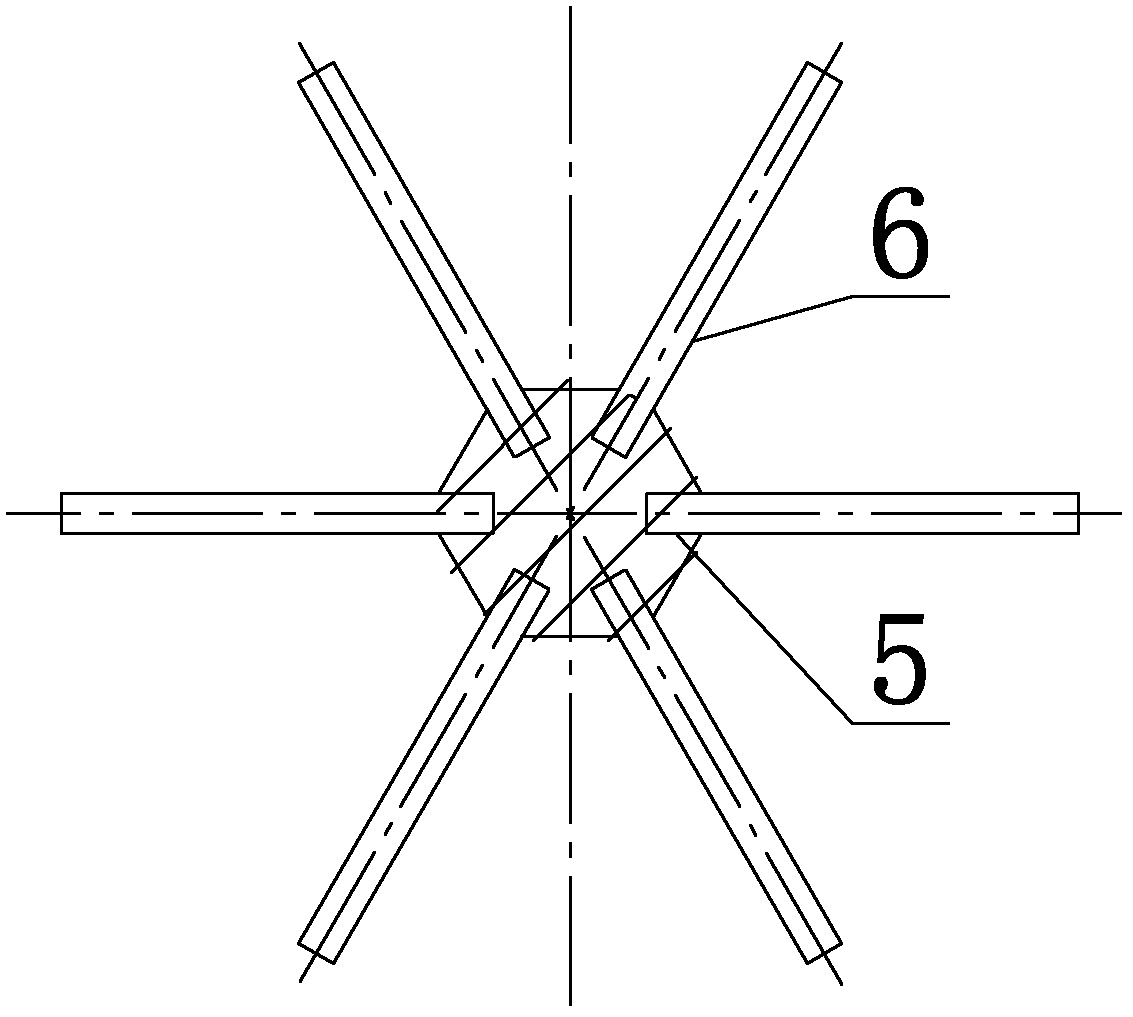

[0043] A protective material anti-cold and heat pulse fatigue test device. The protective material anti-cold and heat pulse fatigue test device specifically includes the following structures: an electric control system 1 and a lifting and rotating device 2, two sample racks, namely sample rack A3 and samples Frame B4, test tank; among them: the electric control system 1 and the lifting and rotating device 2 are connected as a whole; the lifting and rotating device 2 with the rotation axis in the vertical direction is fixedly provided with a sample rack, and the sample rack is fixedly arranged for placing samples 6 sample slot 5;

[0044] The test tank for holding the sample 6 is arranged below the rotation path of the sample holder outside the rotation axis of the lifting and rotating device 2.

[0045] The protective material anti-cold and heat pulse fatigue test device of this embodiment also includes the following content requirements:

[0046] There are two groups of the sample ...

Embodiment 3

[0057] The content of this embodiment is basically the same as that of embodiment 2, and the difference lies in:

[0058] Two sample slots 5 are fixedly arranged on the sample rack A3 and the sample rack B4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com