machine tool cooling pump

A technology for cooling pumps and machine tools, used in pumps, pump components, mechanical equipment, etc., can solve the problems of high-pressure fluid idling vortex loss, low lift and efficiency, and achieve improved utilization, improved efficiency, broad market prospects and promotion value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

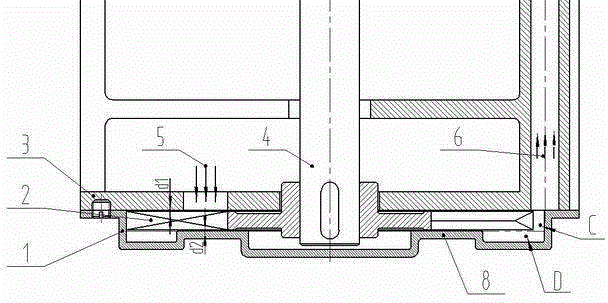

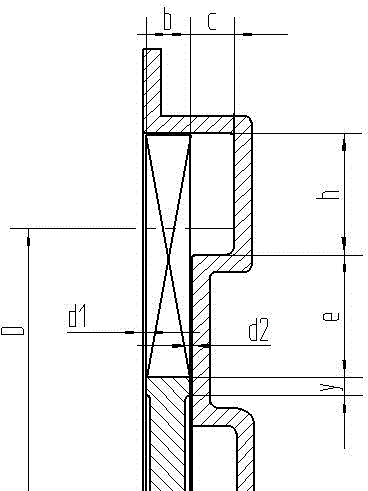

[0030] Such as figure 1 As shown in the schematic diagram of the pump head part of the machine tool cooling pump of the present invention, the present invention is mainly composed of a pump cover 1, an impeller 2, a pump body 3, and a pump shaft 4, which are arranged coaxially from bottom to top; the pump cover 1 and the pump body 3 pass through The set screws are fixed; the impeller 2 is located between the pump cover 1 and the pump body 3, and there are axial gaps d1=0.1mm and d2=0.1mm between the pump cover 1 and the pump body 3 respectively; the impeller 2 and the pump The shaft 4 is fixed and rotates in the circumferential direction relative to the pump cover 1 and the pump body 3; the pump cover 1 is provided with a radial flow passage C at the position corresponding to the width b of the impeller, and is provided with an annular protrusion 8 and a concave flow passage D; The pump body 3 is provided with a water inlet 5 and a water outlet hole 6, both of which communicat...

Embodiment 2

[0050] The machine tool cooling pump in this embodiment is also coaxially arranged sequentially from the bottom to the top by the pump cover 1, the impeller 2, the pump body 3 and the pump shaft 4; the pump cover 1 and the pump body 3 are affixed; the impeller 2 is located between the pump cover 1 and Between the pump body 3 and between the pump cover 1 and the pump body 3, there are axial clearances of d1=0.3mm and d2=0.3mm respectively; The body 3 rotates in the circumferential direction; the pump cover 1 is provided with a radial flow channel C corresponding to the impeller width b, and is provided with an annular protrusion 8 and a concave flow channel D; the pump body 3 is provided with a water inlet 5 and The water outlet hole 6 communicates with the flow channels C and D; the pump shaft 4 runs through the impeller 2 and the pump body 3 , leaving an axial gap with the pump cover 1 .

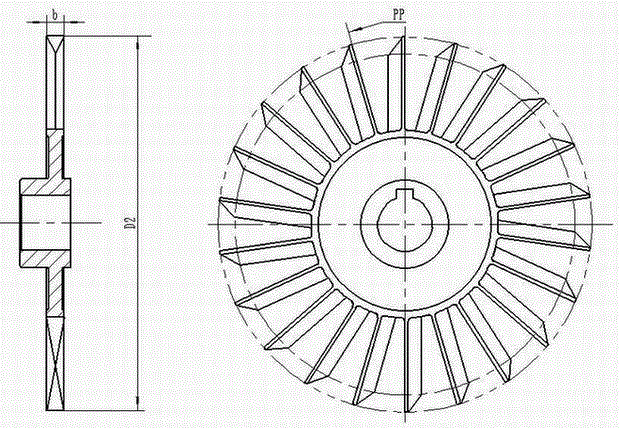

[0051] figure 2 It is a schematic diagram of the structure of the impeller 2 of the p...

Embodiment 3

[0070] The machine tool cooling pump in this embodiment consists of pump cover 1, impeller 2, pump body 3 and pump shaft 4 arranged coaxially from bottom to top; pump cover 1 and pump body 3 are fixed; impeller 2 is located between pump cover 1 and pump There are axial gaps d1=0.2mm and d2=0.2mm between the pump body 3 and between the pump cover 1 and the pump body 3 respectively; Rotate in the circumferential direction; the pump cover 1 is provided with a radial flow channel C at the position corresponding to the impeller width b, and is provided with an annular protrusion 8 and a concave flow channel D; the pump body 3 is provided with a water inlet 5 and a water outlet hole 6. It communicates with the flow channels C and D; the pump shaft 4 runs through the impeller 2 and the pump body 3, leaving an axial gap with the pump cover 1.

[0071] figure 2 It is a schematic diagram of the structure of the impeller 2 of the present invention. Considering the application of machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com