Ballastless track bed plate elevation rapid inspection vehicle

A ballastless track and base plate technology, which is applied to tracks, track maintenance, roads, etc., can solve problems such as surface elevation errors on the base plate, and achieve the effects of improving construction efficiency, real-time detection, and improving the level of construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

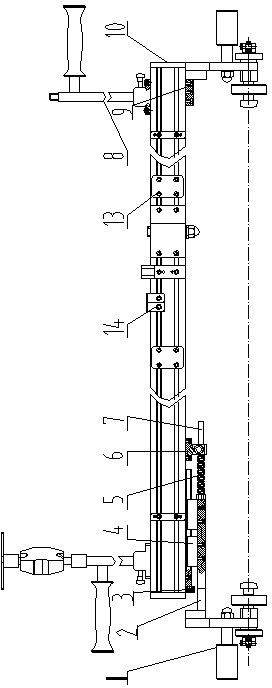

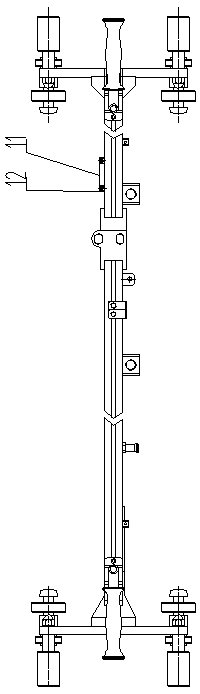

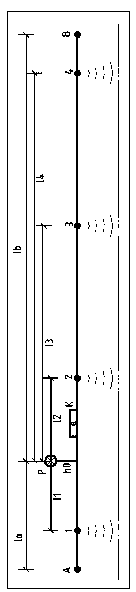

[0017] Including the wheel seat body 1 across both sides of the base plate, such as figure 1 , 2 As shown, one side of the wheel seat body 1 is provided with a movable pulley plate seat 2, and one end of the movable pulley plate seat 2 is connected to a spring guide rod 7, and the spring guide rod 7 is provided with a compression spring 5 and a spring retainer seat 6, and the spring retainer seat 6 is connected to A crossbeam 10, the movable pulley seat 2 is provided with a guide rail 4; the other side of the wheel base body 1 is connected to the crossbeam 10 through the pulley seat 9; the crossbeam 10 is provided with a battery box plug-in plate 11, a battery box socket 12, a cable Lock seat 14; the beam 10 is provided with a prism, an inclination sensor and 4 sonar sensors, and the prism, inclination sensor and sonar sensor are connected with the total station.

[0018] One end of the crossbeam 10 is provided with a rail retaining seat 3 , two ends of the crossbeam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com