Biogas fermentation accelerant and preparation method thereof

A technology of biogas fermentation and accelerator, applied in the direction of fermentation, waste fuel, etc., can solve the problems of slow start of fermentation, low efficiency of production period, and restrictions on the promotion and popularization of biogas projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

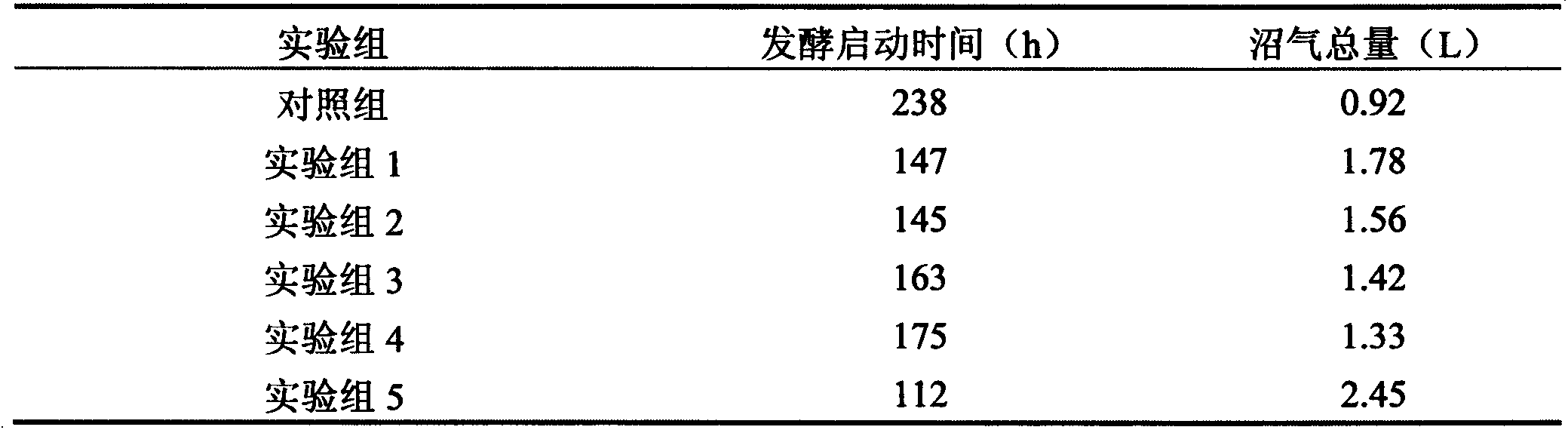

[0009] Embodiment 1: Effect of biogas fermentation accelerator on fermentation start-up time and gas production

[0010] In this experiment, cow dung was selected as the substrate for fermentation in a 1L fermenter, and the fermentation was run for 60 days. In the process of biogas fermentation, the fermentation with iron, cobalt, nickel and zinc metal elements alone, the biogas fermentation with this accelerator and the biogas fermentation without adding any substances were compared, and the start-up time of biogas fermentation in each group was compared, so as to prove that the biogas Additives can promote the start of biogas fermentation to a certain extent.

[0011] application:

[0012] Experimental group 1: Biogas fermentation was carried out in a 1L fermenter with cow dung as the substrate, ferric chloride was prepared into a concentrated salt solution, and 0.1mg / L / d was fixed into the reactor with a syringe every day, and the gas was collected by a drainage collector....

Embodiment 2

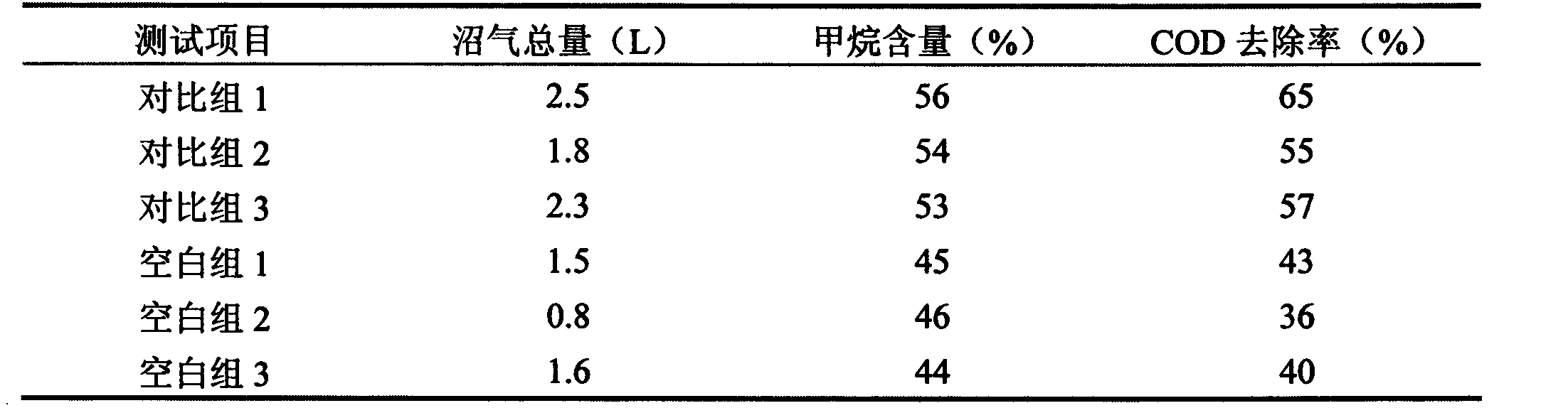

[0021] Example 2: Fermentation was carried out in a 1L fermenter by selecting cow dung, pig manure, and sheep dung as substrates. During the biogas fermentation, the biogas fermentation with this accelerator was compared with the biogas fermentation without adding any substances. The biogas The fermentation time was 60 days, and the total gas production, methane content in biogas, and COD removal rate of each group were compared, which showed that the biogas fermentation accelerator had a good promoting effect on various indicators of biogas fermentation.

[0022] Contrast group 1: The cow dung substrate was selected for fermentation in a 1L fermenter. During the process of biogas fermentation, this accelerator was added to the fermenter for biogas fermentation every day. The gas collection was carried out by drainage and gas collection. The COD removal rate was based on the reaction Calculation of COD values before and after

[0023] Contrast group 2: pig manure substrate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com