A composition containing polyethylene terephthalate and its preparation method

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of compositions containing polyethylene terephthalate, and can solve problems such as increased viscosity and difficulty in extrusion , achieve the effect of lower torque value, higher strength and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

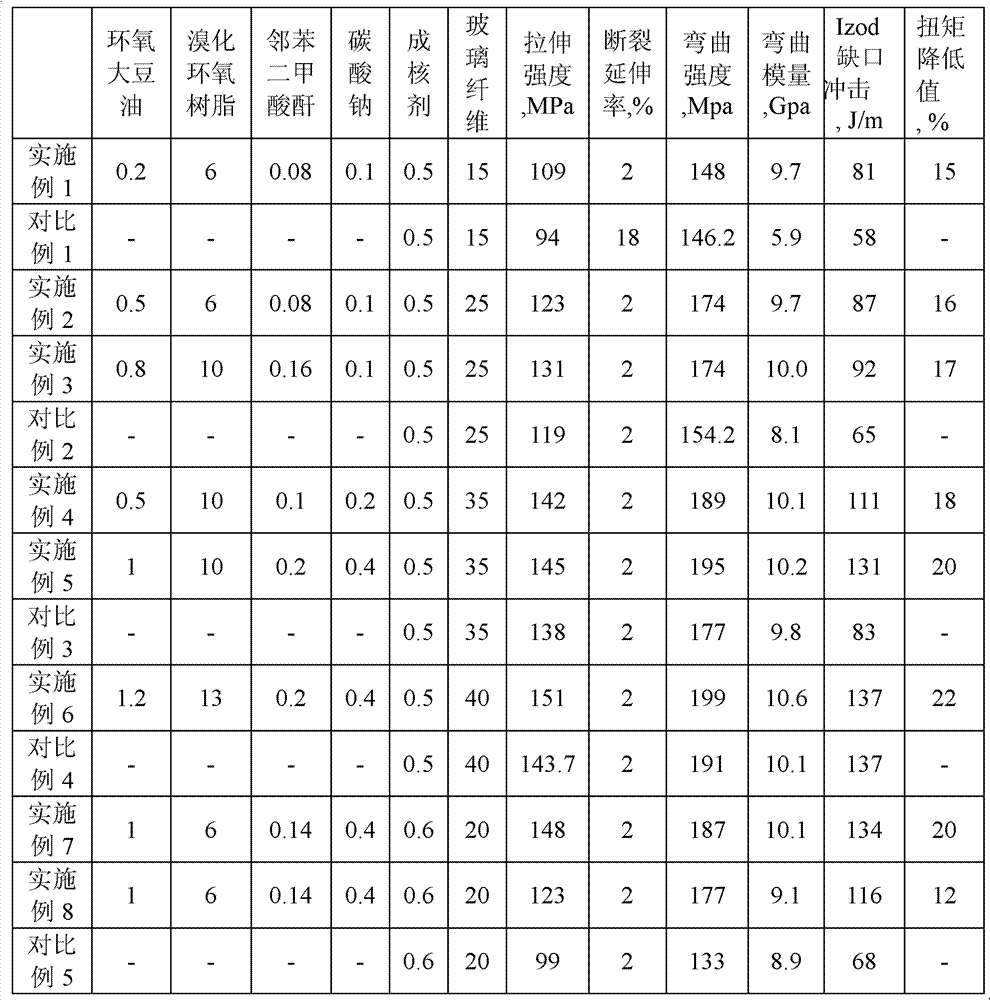

Examples

preparation example Construction

[0033] In the preparation method of the present invention, in order to further improve the performance of the polyethylene terephthalate-containing composition, it is preferable that the above-mentioned mixture undergoes a 3-5 minute high-speed stirring process before melt extrusion. The uniformly stirred mixture is melt-extruded, and the processability of the obtained composition is better.

[0034] In the preparation method of the present invention, the glass fiber and sodium carbonate are added during extrusion, wherein the glass fiber is added through the glass fiber port of the extruder, and the sodium carbonate is added through a side screw.

[0035] When the composition to be prepared is a composition containing at least one of antioxidant, flame retardant and toughening agent, the timing and way of adding the antioxidant, flame retardant and toughening agent can refer to existing technology. Preferably, the flame retardant is added during the extrusion process, and it...

Embodiment 1

[0054] 100 parts of polyethylene terephthalate (intrinsic viscosity is 0.7dl / g) chips, 5 parts of ultra-fine pyrene-butadiene powder rubber (particle size is 50-150 nanometers), 0.5 parts of sodium benzoate, 0.3 parts Antioxidant (weight ratio of antioxidant 1010 to antioxidant 168 is 2:1), 0.2 parts of epoxy soybean oil (epoxy value ≥ 6.0, iodine value ≤ 6.0, chemically pure), 6 parts of brominated epoxy resin (trade name BEP-3) and 0.08 parts of phthalic anhydride are put into a high-speed mixer, stirred at room temperature for 4 minutes, and stirred evenly. Using WP ZSK25 twin-screw, the temperature in each section is 230-245-255-260-260 Melt extrusion at a temperature of -255°C, and add 15 parts of glass fiber (product model 1000#), 0.1 part of sodium carbonate and 12 parts of flame retardant (decabromodiphenyl ether and Sb 2 o 3 The weight ratio is 4:1), the time of melt extrusion is 30 seconds, after extrusion, it is cooled and pelletized, and then dried in an oven at a...

Embodiment 2

[0058] Slice 100 parts of polyethylene terephthalate (intrinsic viscosity 1dl / g), 3 parts of ultra-fine styrene-butadiene powder rubber (particle size is 50-150 nanometers), 0.5 parts of sodium benzoate, 0.1 parts of anti- Oxygen agent (weight ratio of antioxidant 1010 and antioxidant 168 is 3: 1), 0.5 parts of epoxy soybean oil (epoxy value ≥ 6.0, iodine value ≤ 6.0, chemically pure), 6 parts of brominated epoxy resin ( Brand name BEP-3) and 0.08 parts of phthalic anhydride are put together in a high-speed mixer, stirred at room temperature for 5 minutes, and stirred evenly. Using WP ZSK25 twin-screw, the temperature in each section is 230-245-255-260-260- Melt extrusion at a temperature of 255°C, and add 25 parts of glass fiber (product model 1000#), 0.1 part of sodium carbonate and 10 parts of flame retardant (decabromodiphenyl ether and Sb 2 o 3 The weight ratio is 2:1), the time of melt extrusion is 50 seconds, after extrusion, it is cooled and pelletized, and then dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com