Can opener

A technology of can opener and occluder, which is applied in the disassembly of disc closures, etc., which can solve the problems of non-conformity with environmental protection, opening nine cows and two tiger dishes, and reducing the value of reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

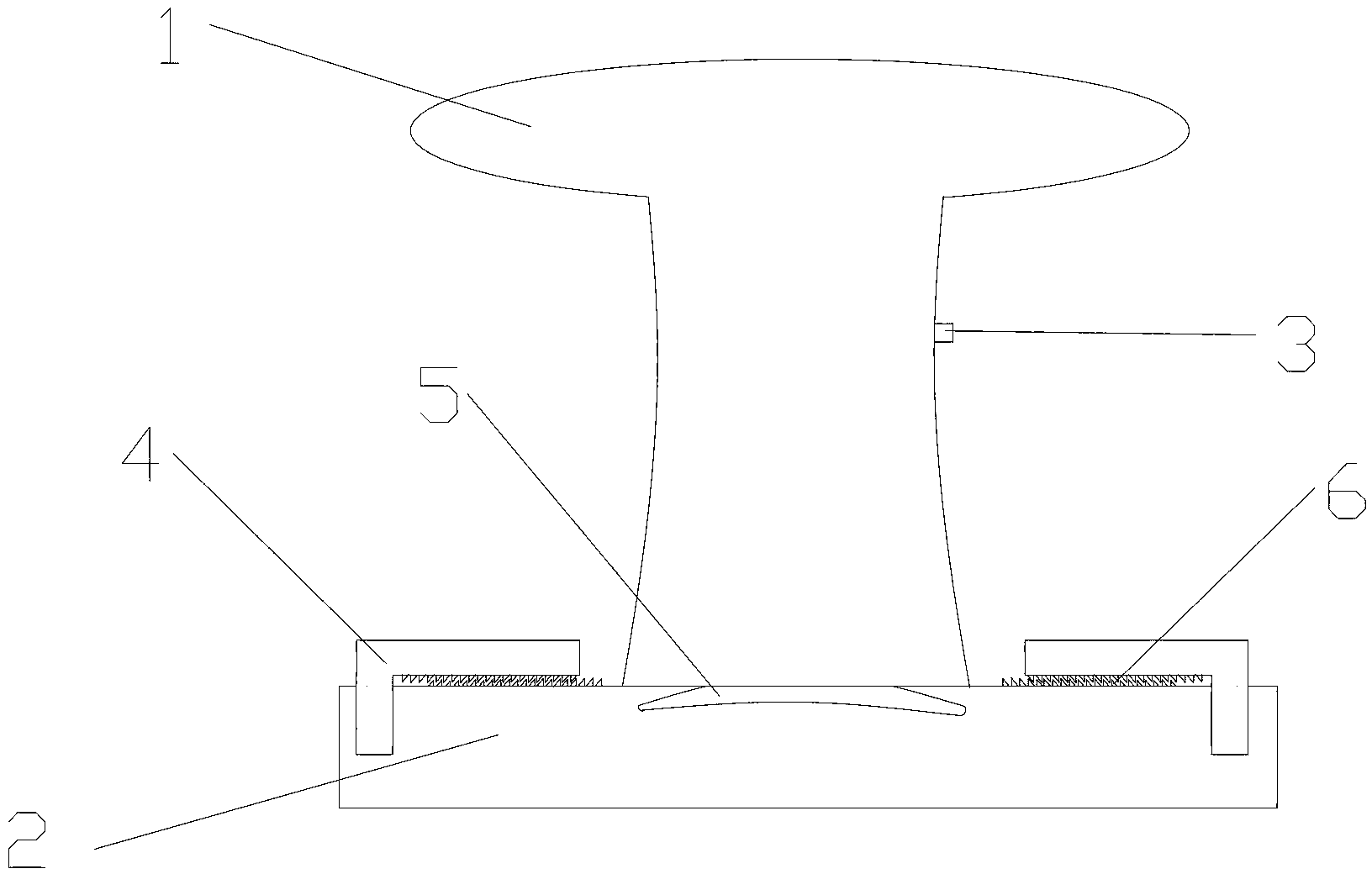

[0012] A can opener, comprising a handle 1 and a occluder 2, the handle is fixedly arranged at the center of the occluder, the occluder includes a thimble 3, a suction cup 5, inverted teeth 6 and a mouthpiece 4, the suction cup is fixedly arranged on the bottom of the occluder, The bottom of the mouthpiece is equipped with inverted teeth, and the upper surface of the articulator is equipped with positive and inverted teeth. The inverted teeth are arranged in a ring shape. The mouthpiece and the articulator are locked and set, and the mouthpiece is pushed inward to make the mouthpiece and the lid fully contact. , The number of mouthpieces is at least 3, and multiple mouthpieces can fully contact the can lid to bear the force. One end of the thimble is set at the handle, and the other end is set in the suction cup. Press the thimble to release the suction cup adsorbed on the can lid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com