Integrated vehicle trunk lid hinge reinforcing plate support structure

A technology for hinge reinforcement plates and trunk lids, which is applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve problems affecting machining accuracy, error accumulation, waste of man-hours, etc., and achieve enhanced stiffness performance and increased stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

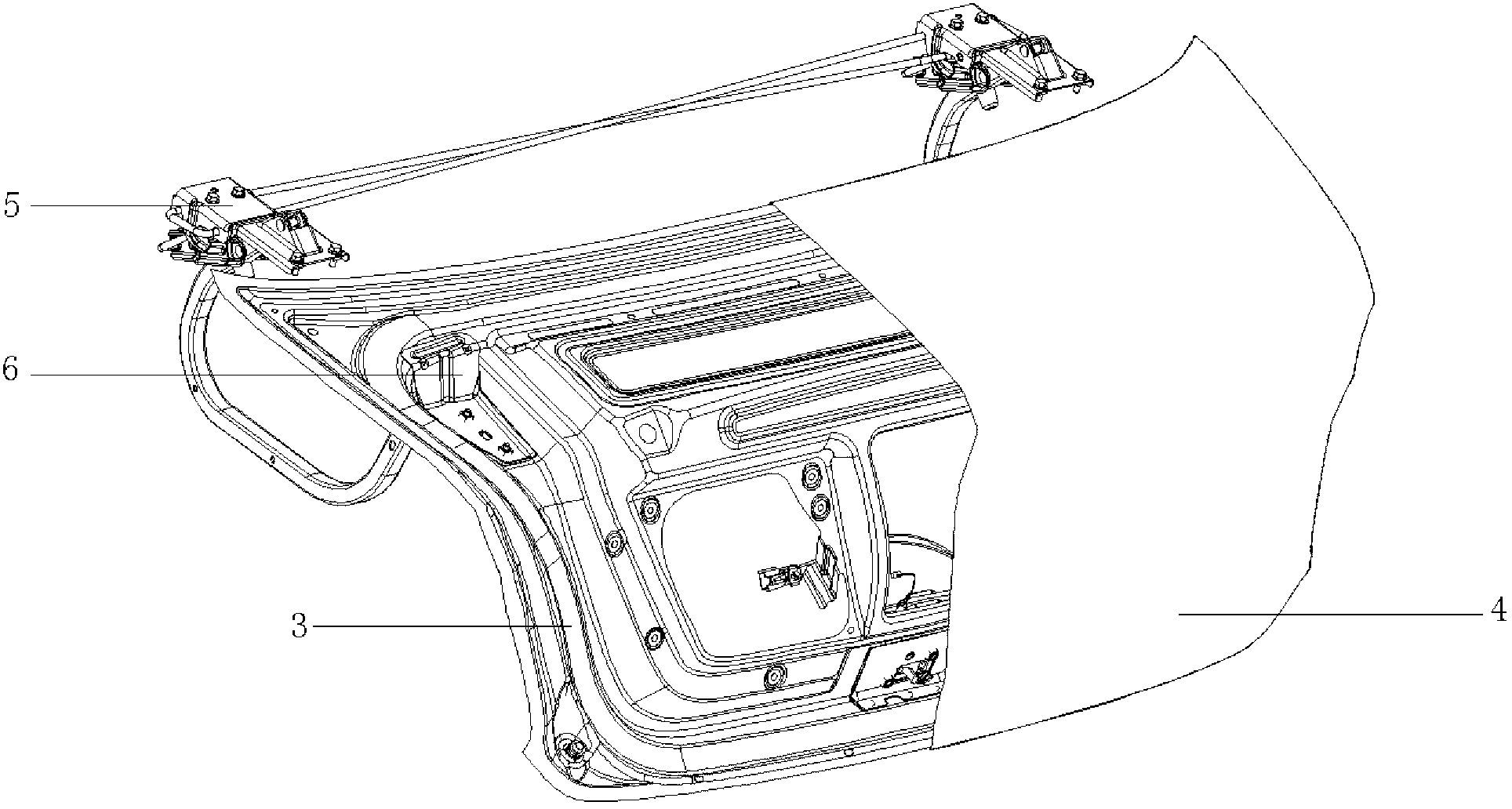

[0038] see figure 2 As shown, the embodiment of the present invention provides a one-piece car trunk lid hinge reinforcement plate support structure, which improves the hinge reinforcement plate 1 and the outer panel support plate 2 of the trunk lid in the prior art, and is provided with an integrally formed The hinge reinforcement plate bracket assembly 6 is welded on the trunk lid inner panel 3 at one time, which is used to enhance the rigidity of the existing trunk lid outer panel 4 and the hinge assembly 5 mounting plate of the car, so that the rigidity here is not easy to occur out of shape. In addition, a separate outer plate support plate 2 is saved, the total weight of the body in white is reduced, and the goal of lightweight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com