Printer dolly with ultraviolet curing function

A printer and ultraviolet technology, applied in the direction of printing device, printing, etc., can solve the problems of unstable electric heating power consumption, unadjustable height of the printer carriage, unsafe, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

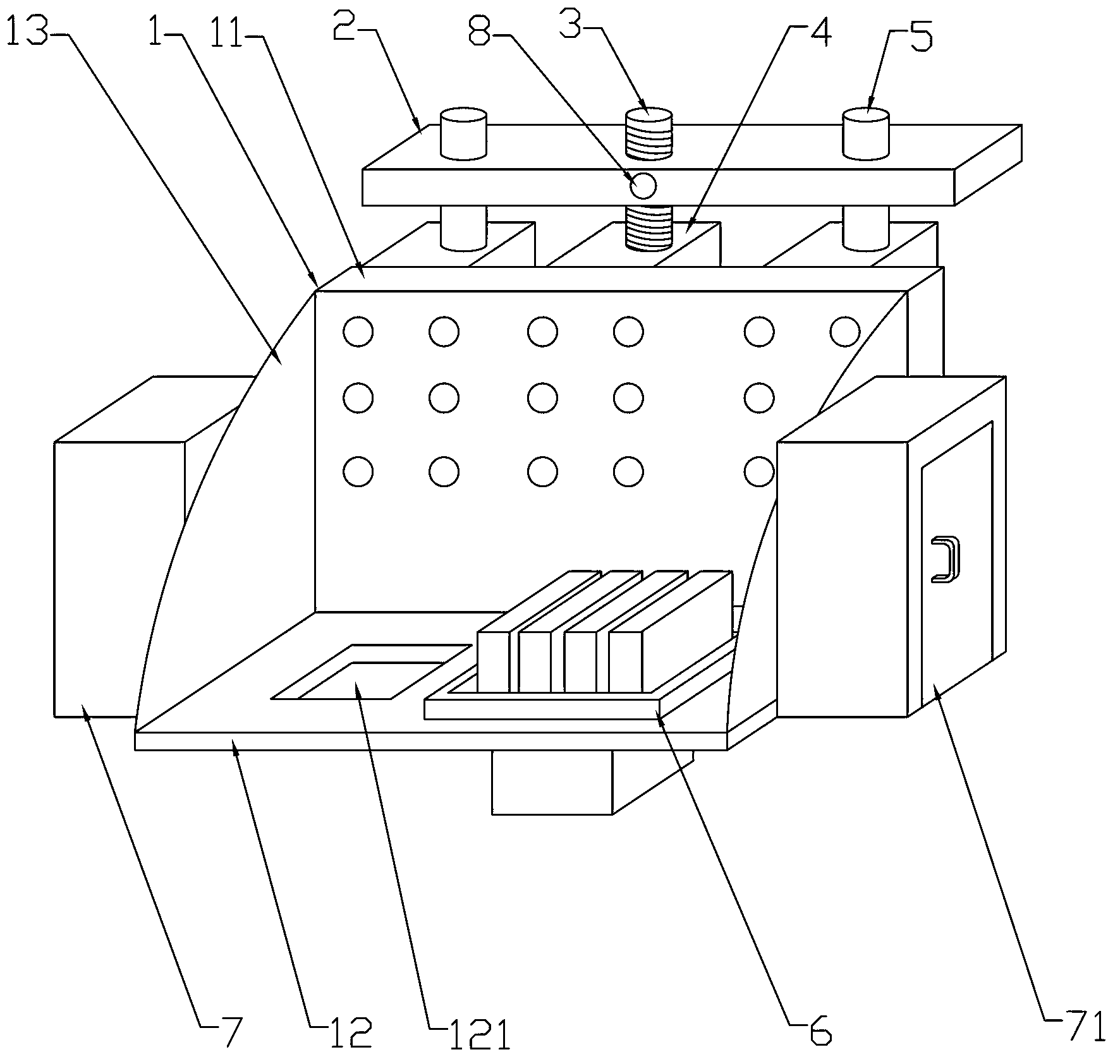

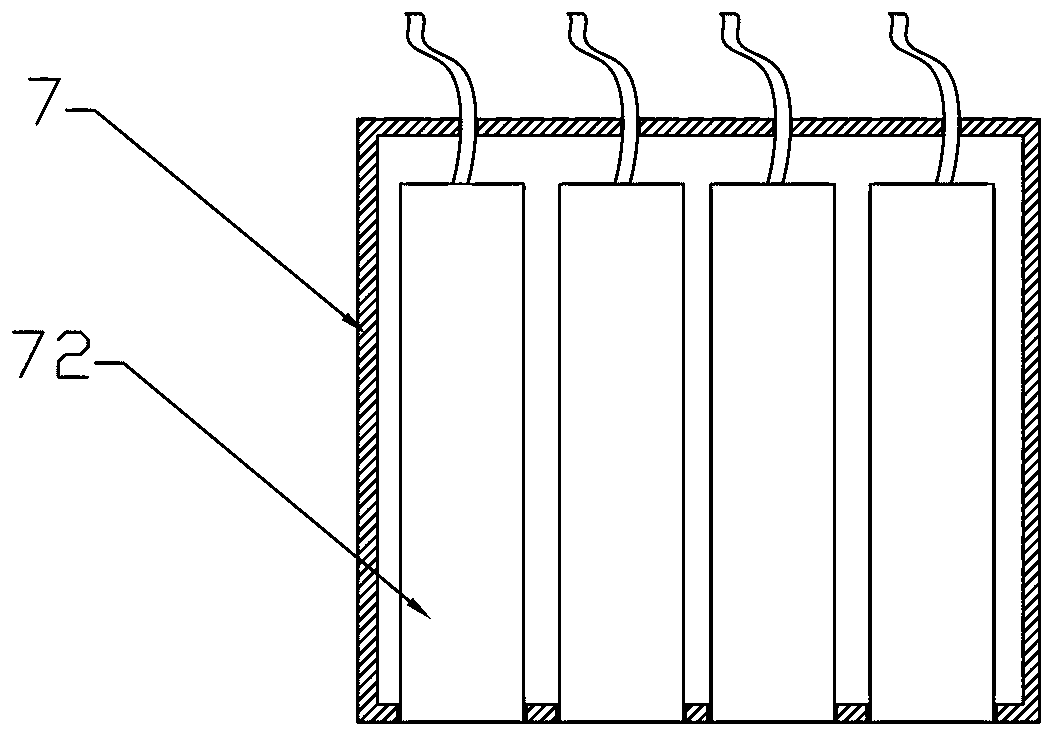

[0012] like figure 1 As shown, the printer trolley of the invention includes a trolley frame 1, an adjustment plate 2, an adjustment bolt 3, a fixed block 4, a guide column 5, an inkjet device 6 and a heating box 7, and the trolley frame 1 includes a vertical Plate 11, bottom plate 12 and side plate 13, described side plate 13 is a pair, vertical plate 11 and bottom plate 12 are respectively fixed between two side plates 13, and described vertical plate 11 is vertically fixed on the bottom plate 12 The base plate 12 is provided with a plurality of through openings 121, and the inkjet device 6 is disposed in the openings 121.

[0013] There are three fixed blocks 4, and they are respectively fixed on the outside of the vertical plate 11 by bolts, the described guide columns 5 are two cylinders, and the described adjustment bolts 3 and the two guide columns 5 are arranged from top to bottom The adjustment plate 2 and the fixed block 4 are passed through in turn, and the three f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com