A cutting and pressing wheel for electrode material

An electrode material and pressure roller technology, applied in the field of electrode material slitting equipment, can solve the problems of no slitting press roller, electrode material deviation, scrapping of electrode materials, etc. Adjustable, good compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

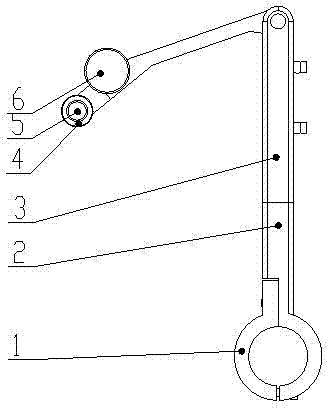

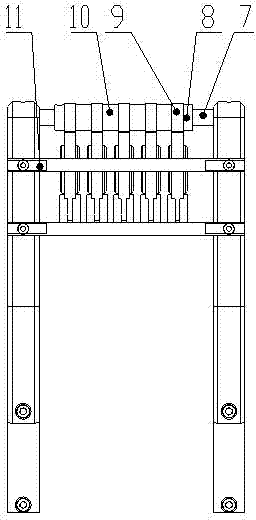

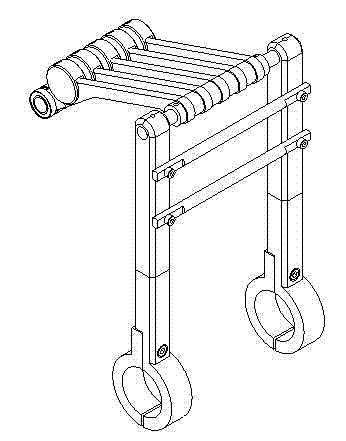

[0014] The present invention as figure 1 and figure 2 As shown, two left fixed half rings 1 and two right fixed half rings 2 are fixed on the small slitting machine, and then the main support rod 3 is installed on the right fixed half ring 2, and two limit shafts 11 are installed on the two Between two main support rods 3, the two ends are fixed on two main support rods, a fixed shaft 7 is installed on the top of the main support rod 3, and two stop rings 8 and a plurality of pressure roller arms 9 are installed on the fixed shaft 7. and spacer ring 10, two limit rings are located at both ends, a plurality of pressure roller arms 9 and spacer rings 10 are arranged at intervals, the pressure roller arms 9 can rotate around the fixed shaft 7, and the pressure roller arms 9 are limited by the limit shaft 11, The front end of the pressure roller arm 9 is respectively eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com