Welding fixture for reinforcing ribs of knee guard bar

A technology for welding tooling and protection rods, which is applied in the field of tooling and fixtures, can solve the problems of large welding errors and burrs, and achieves the effects of small welding errors and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

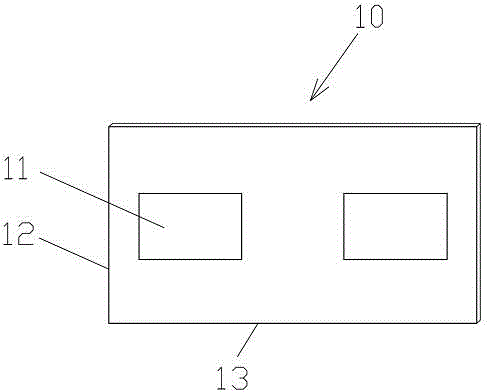

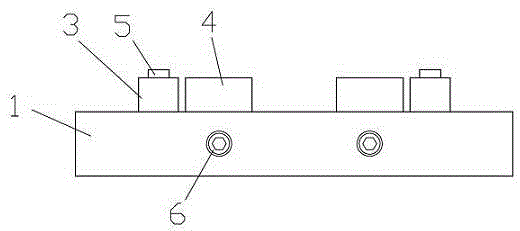

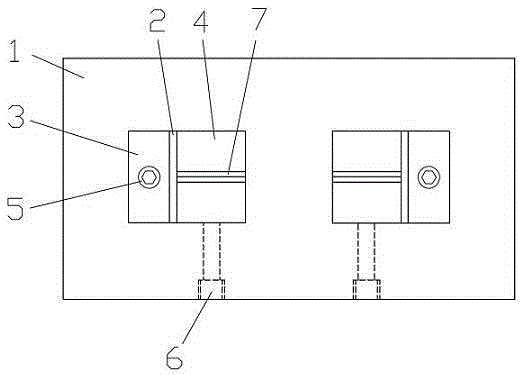

[0014] The invention discloses a welding frock for the reinforcing bar of the knee protection bar, such as Figure 2 to Figure 3 As shown, it includes a rectangular base 1, and the upper surface of the base 1 is provided with two grooves 2 corresponding to the through holes of the knee protection bar reinforcement ribs. The groove 2 is provided with a first direction positioning block 3 and a second direction positioning block 4, and the first direction positioning block 3 respectively arranged in the two grooves 2 is locked by a locking bolt 5 and used for the knee The positioning of the first direction of the protective bar reinforcement 10; each of the grooves 2 is provided with at least two second direction positioning blocks 4, which are locked by the tightening bolt 6 and used for the positioning of the knee protection bar reinforcement 10 Orientation in the second direction. The locking bolt 5 is arranged on the upper surface of the positioning block 3 in the first dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com