Novel small gas-water backwashing filtration tank

A technology of backwashing and filtering tanks, applied in the field of water treatment, can solve the problems of high operating costs, large investment in equipment, complicated operation, etc., and achieve the effects of preventing the loss of filter materials, prolonging the renovation period, and improving the effect of backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

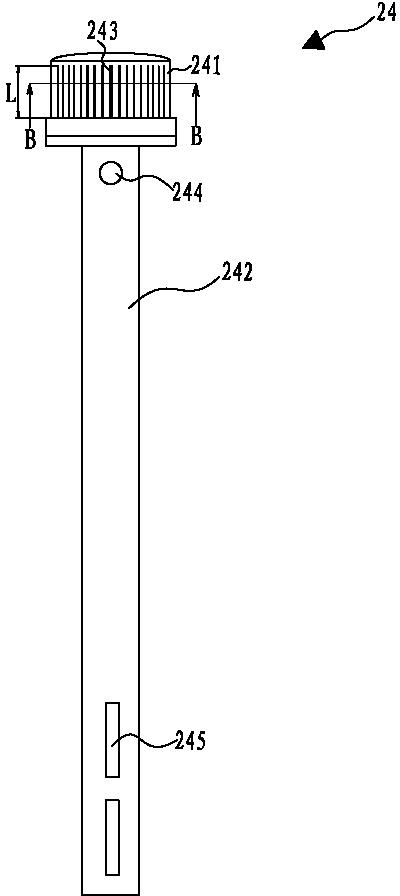

[0047] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, a new type of small air-water backwash filter tank, including a tank body, the tank body can be divided into 2 to 6 filter cells, each filter Filter area is not more than 30m 2 .

[0048] The filter grid is provided with a water inlet area 10, a filter area 20, and a water and air distribution area 30; each filter grid is provided with a water inlet 11, and each water inlet 11 is connected to a water inlet branch pipe 12, and each water inlet branch pipe 12 is connected to an inlet The water main pipe 13 is in communication; the water inlet 11 is in communication with the water inlet area 10.

[0049] The water inlet area 10 is provided with a backwash waste water tank 14, and the bottom of the backwash waste water tank 14 is provided with a sewage outlet 141. The backwash waste water tank 14 and the filter area 20 are separated by a baffle 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com