Preparation method for optical thin-film of polaroid

An optical film and polarizer technology, applied in the optical field, can solve the problems of easy dust accumulation, high material consumption, and low service life, and achieve the effects of reducing fatigue, good wear resistance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

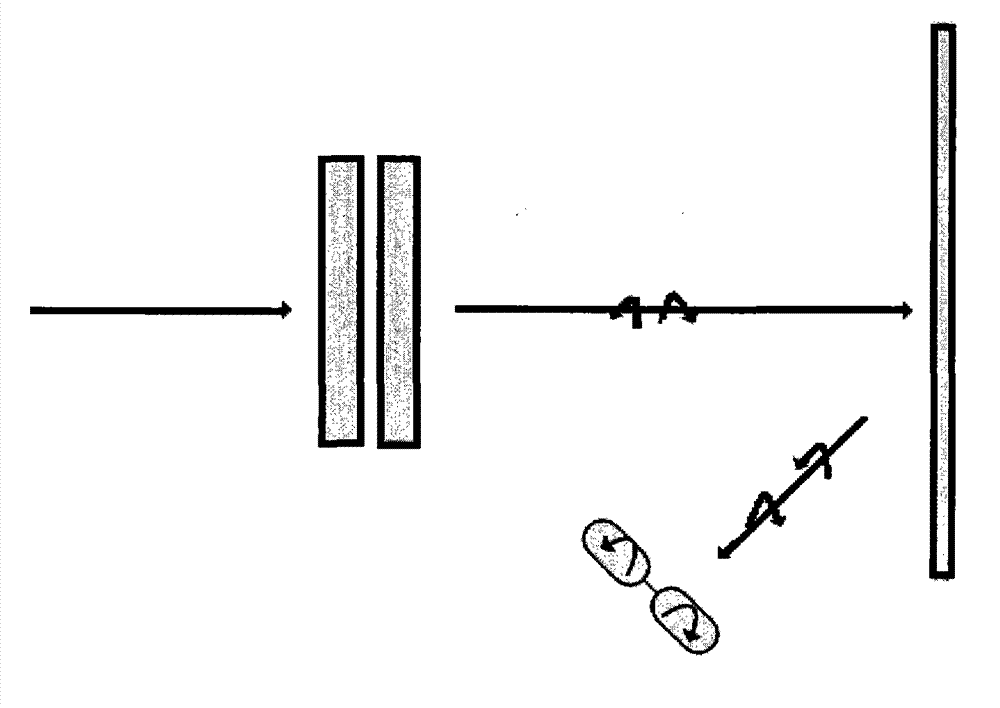

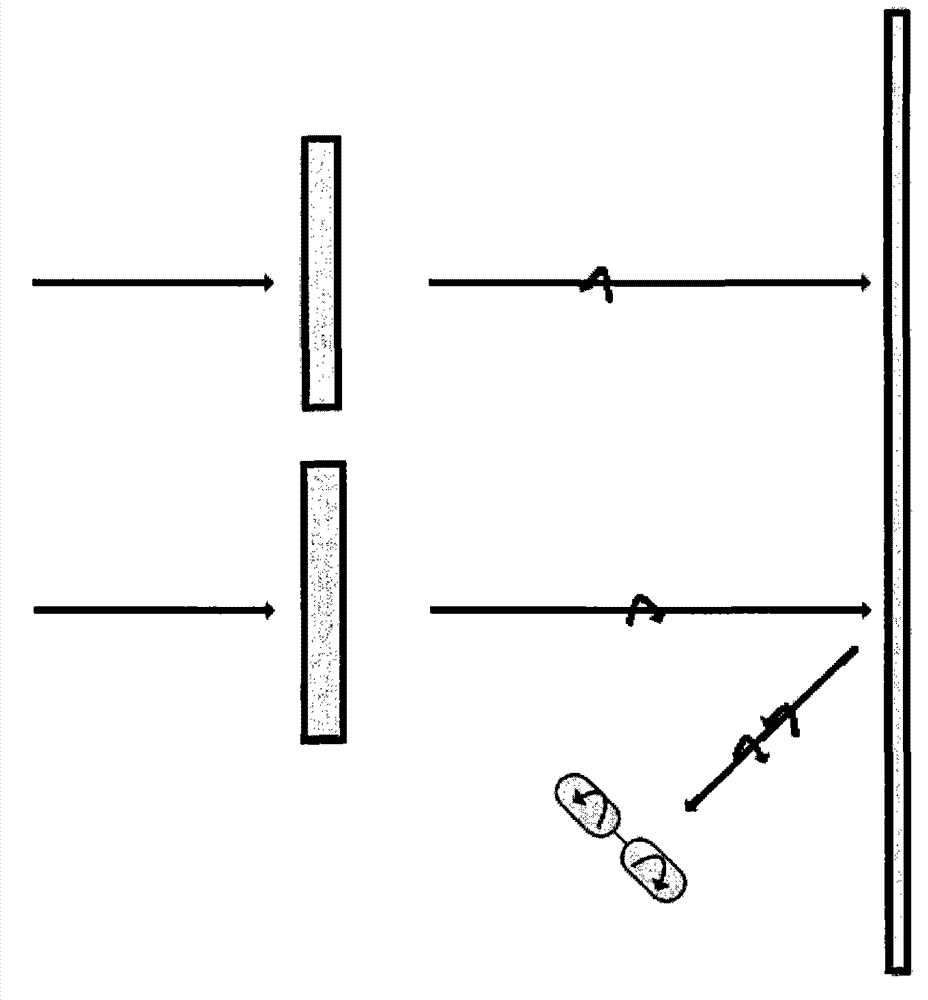

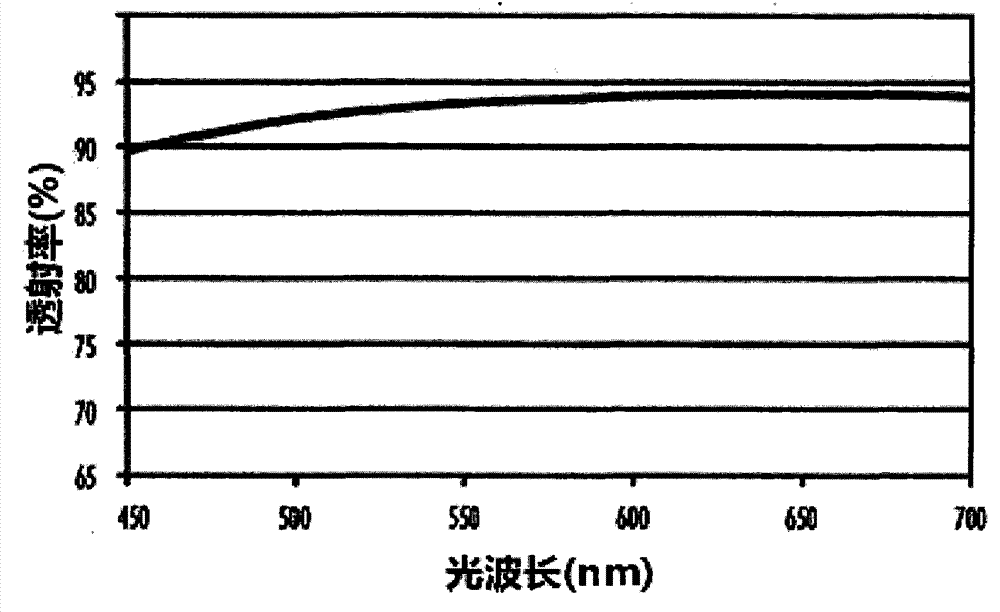

Image

Examples

Embodiment Construction

[0018] The preparation method of polarizer optical film of the present invention comprises the following steps:

[0019] Step 100: pre-plating treatment

[0020] Provide polarizers with optical glass matrix or resin matrix; then pre-treat them, including degreasing, pickling, cleaning and other steps to clean the surface of the polarizers;

[0021] Step 110: Chemical vapor deposition of nano-ceramic film

[0022] The nano-ceramic thin film is deposited in a chemical vapor deposition reactor, the gas is supplied by a gas supply pipe and the flow of each gas is controlled by a flow meter. The reaction system is ZnCl 2 -H 2 S-BCl 3 -H 2 O-O 2 -H 2 , the reaction temperature is 380-420°C, the working pressure is 1000-1500Pa, where ZnCl 2 The flow rate is 50ml / min, H 2 The flow rate of S is 15-35ml / min, BCl 3 The flow rate is 20-25ml / min, H 2 The flow rate of O is 5-20 ml / min, O 2 The flow rate is 5-10ml / min, H 2 The flow rate is 500ml / min, the deposition time is 3-10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com